Hydraulic control system of safety stop valve

A technology of hydraulic control system and safety cut-off valve, which is applied in the direction of fluid pressure actuation system safety, fluid pressure actuation device, servo motor, etc. It can solve the problems of electric gate valves being unable to move, slow in speed, and not meeting safety requirements, etc., to achieve Fast recovery of fire protection function, convenient and simple operation, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

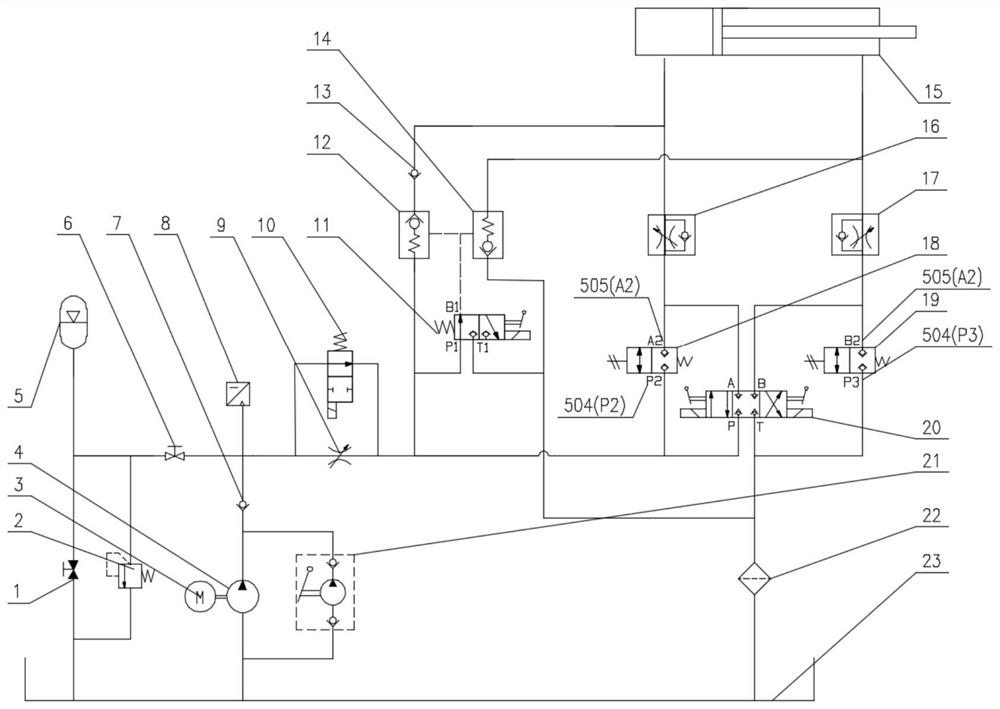

[0030] see figure 1 As shown, the hydraulic control system of the present invention includes an accumulator 5, a first fire damper 18, a second fire damper 19, an oil circuit connected to the upper chamber of the actuator cylinder 5, an oil passage connected to the lower chamber of the actuator cylinder 5, and an oil tank 23 The oil return circuit; wherein: the valve-closing oil circuit is provided with a valve-opening control valve, and the valve-closing control valve is respectively connected with the accumulator, the oil circuit connected to the upper chamber of the executive cylinder, the oil circuit connected to the upper chamber of the executive cylinder, and the The oil circuit of the fuel tank is connected to form a valve-closing oil circuit; the first fire damper is connected in parallel with the valve-closing control valve, and the first fire damper is respectively connected to the accumulator and the oil circuit connected to the upper chamber of the executive oil cyl...

Embodiment 2

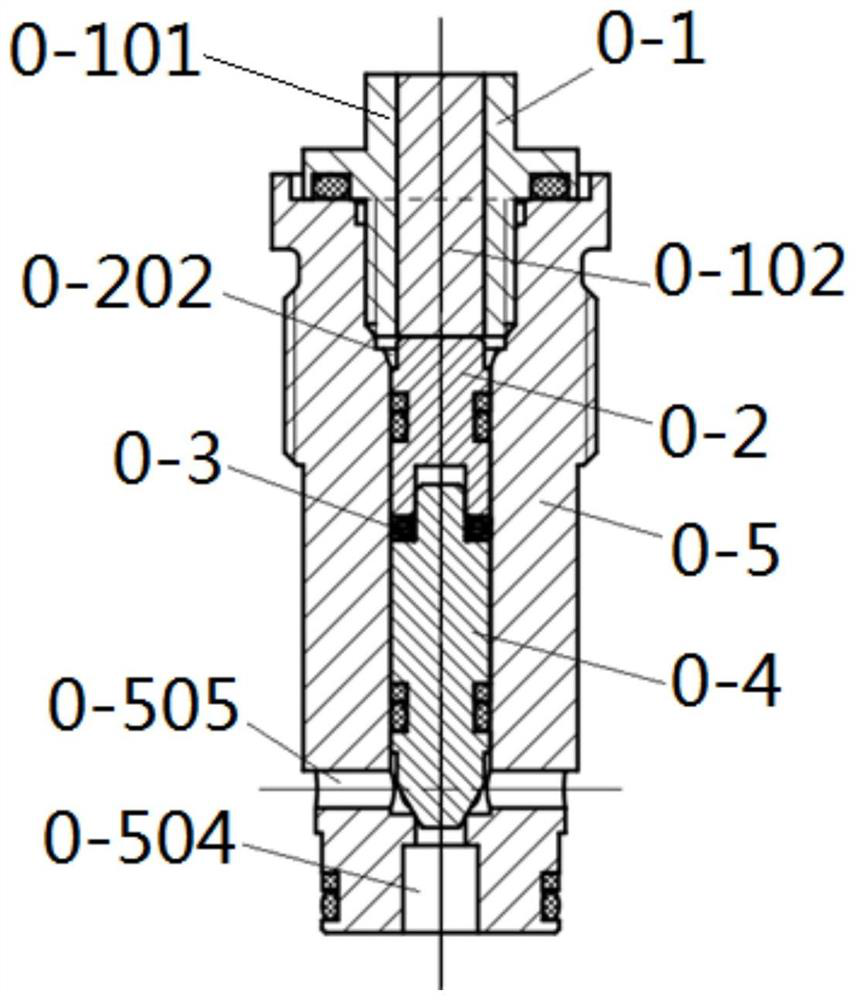

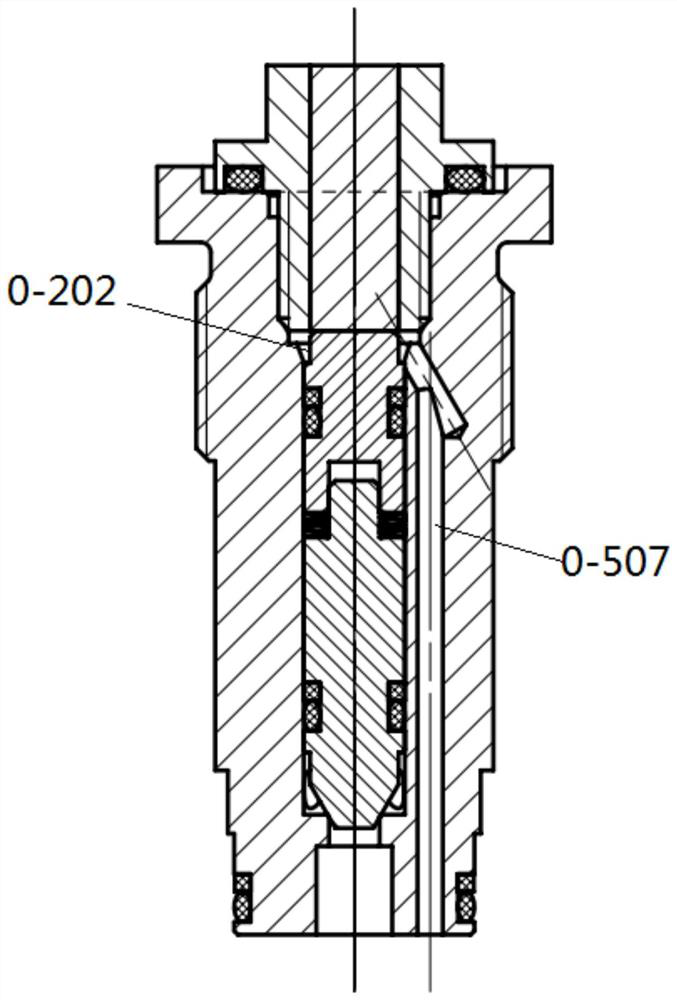

[0039] The first fire damper or / second fire damper of the present invention can be selected from commercially available fire dampers, and in a preferred example, can adopt figure 2 The fire damper shown, the fire damper valve includes fusible plug 0-1, valve body 0-5, valve core 0-4, pressure sleeve 0-2 and spring 0-3; the valve body is provided with a working through hole in the axial direction , one end of the working through hole is used to install the fusible plug, the other end is the medium inlet and outlet 0-504, and the side wall of the medium inlet and outlet is provided with the first inlet and outlet 0-505;

[0040] The valve core, spring and pressure sleeve are sequentially installed in the working through hole along the axial direction, and the fusible plug is installed at one end of the working through hole, pressing the pressure sleeve, spring and valve core in sequence, so that the end of the valve core blocks the medium from entering. The outlet and the first...

Embodiment 3

[0051] In some schemes, the control system of the present invention is provided with an emergency shut-off oil circuit, which is used to shut down the controlled valve in an emergency when the power supply fails. figure 1 As shown, the emergency shutdown oil circuit includes an emergency shutdown solenoid valve 11, a first hydraulic control check valve 12 and a second hydraulic control check valve 14, wherein the emergency shutdown solenoid valve is connected with the accumulator and the first hydraulic control check valve respectively. The pressure guiding port of the check valve, the pressure guiding port of the second hydraulic control check valve are connected to the oil circuit connected to the fuel tank; the first hydraulic control check valve is respectively connected to the accumulator and the oil circuit connected to the upper chamber of the executive cylinder, The second hydraulically controlled one-way valve is respectively connected to the oil return circuit connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com