Reinforcing system for large-scale landslide treatment and construction method thereof

A construction method and landslide technology, which can be used in excavation, infrastructure engineering, climate change adaptation, etc., can solve problems such as increased construction costs, achieve high resistance to horizontal loads, reduce sliding forces, and contribute to long-term stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

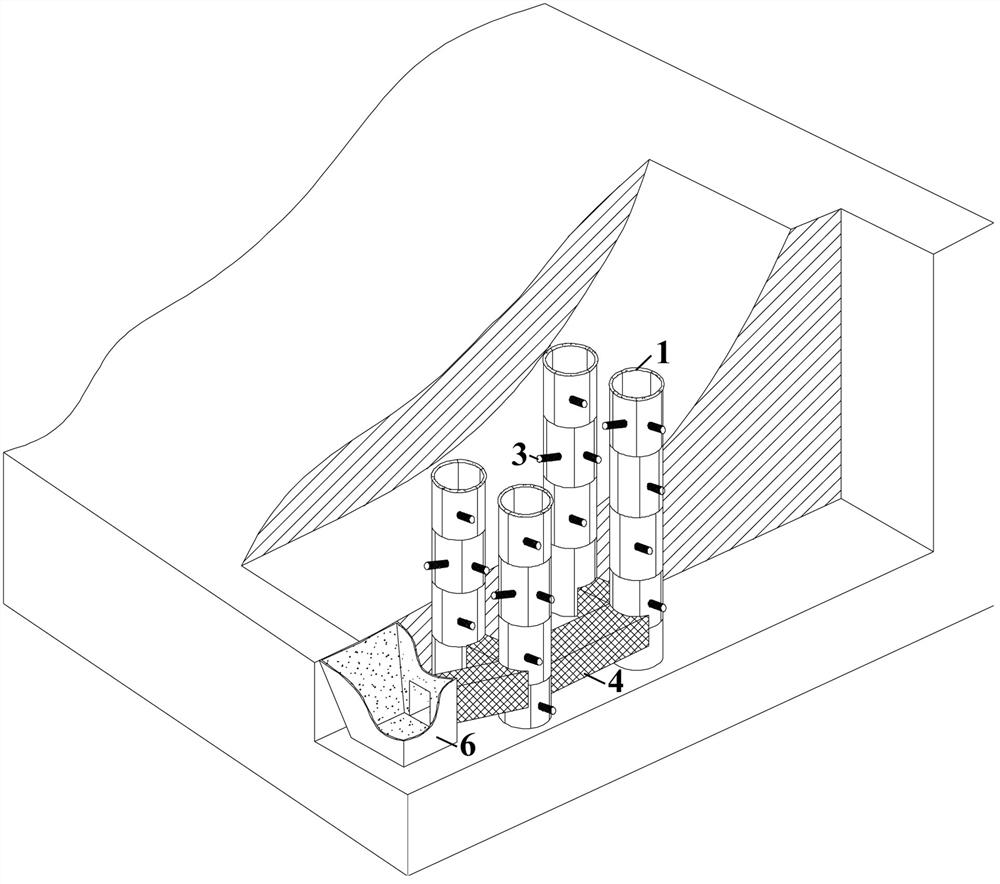

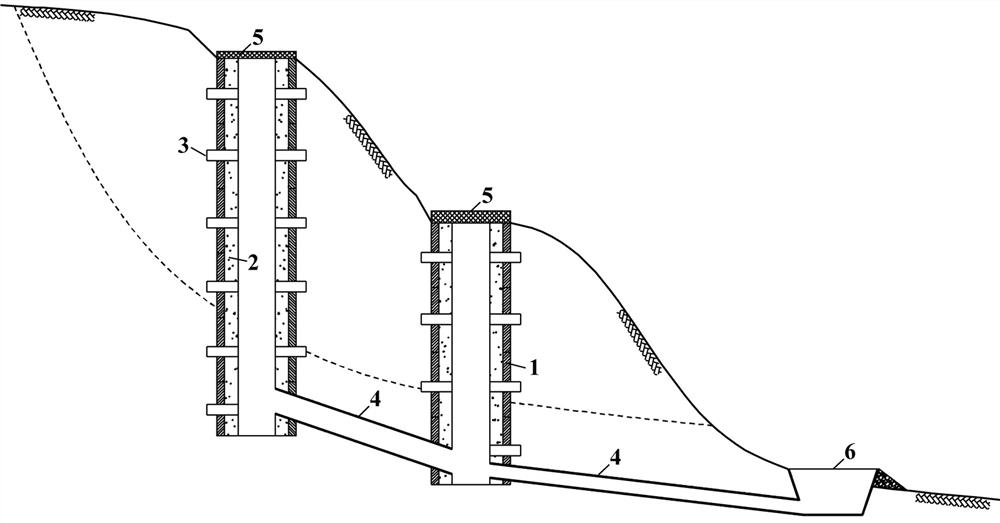

[0047] see Figure 1-8 , a reinforcement system for large-scale landslide treatment, which includes composite assembled caissons arranged inside the landslide body, and the composite assembled caissons that are uniformly distributed form a composite assembled caisson group; the lower part of the composite assembled caisson group They are connected through the collection and drainage culverts 4, and jointly form the drainage channel network of the landslide body, and finally merge into the water collection well 6 to efficiently discharge the groundwater in the landslide body. By adopting the reinforcement system of the above structure, it can not only meet the anti-sliding bearing requirements of large-scale landslides, but also efficiently discharge the groundwater in the landslide body, reduce the sliding force of the slope body, and ensure the long-term stability of the landslide body.

[0048] Further, the composite prefabricated caisson is assembled from prefabricated cais...

Embodiment 2

[0057] A construction method for a reinforcement system for large-scale landslide control, comprising the following steps:

[0058] Step 1, assembly and sinking construction of composite prefabricated caisson:

[0059] Including the assembly of the fabricated caisson segment 1, sinking to the design depth, the construction of the drainage pipe on the outer wall of the caisson and the construction of the reinforced concrete lining on the pipe wall, forming a caisson-lining composite structure to jointly provide the anti-sliding bearing capacity of the slope;

[0060] Step 2, construction of drainage culverts:

[0061] After the construction of the caisson-lining composite structure is completed, the collection and drainage culvert 4 is constructed using the pipe jacking method or the underground excavation method, and the composite assembled caissons are connected through the collection and drainage culvert 4 to form a drainage channel network for the landslide body. Effective...

Embodiment 3

[0065] The concrete construction process of described step 1 comprises the following steps:

[0066] Step 1.1, according to the design requirements, level the surface of the area to be reinforced by manual or small-scale mechanical leveling, the leveling area should be larger than the outer diameter of the composite prefabricated caisson; at the same time, lay plain concrete or sand and gravel cushion on the leveled surface , the thickness of the cushion layer is about 100mm, which provides a stable and reliable working surface for subsequent caisson construction and material stacking;

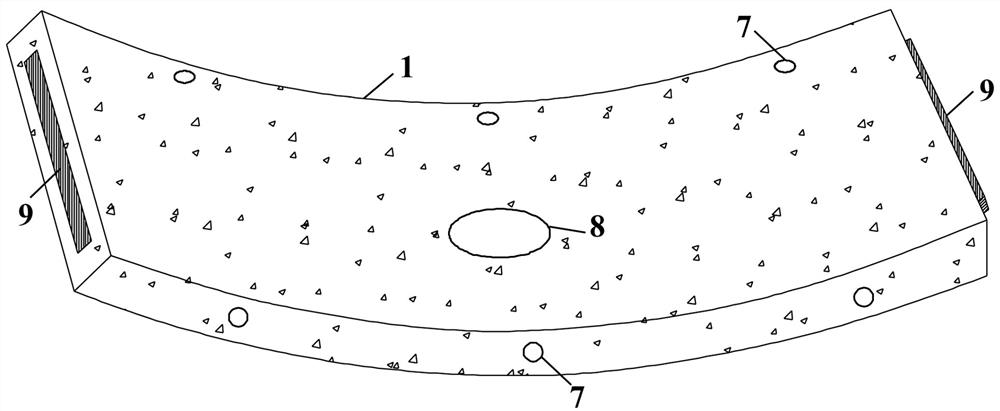

[0067] In step 1.2, the assembled caisson segment 1 is connected as a ring segment through the connecting screw 10 and placed on the surface cushion, and each ring segment is assembled from 5 to 7 assembled caisson segments 1; for the convenience of follow-up For culvert construction, the diameter of each ring segment is greater than 2m, the height of each ring segment is 0.8~1.2m, and the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com