Composite material with stepped hole structure distribution and preparation method thereof

A technology of composite materials and stepped pores, which is applied in the direction of molecular sieve compounds, chemical instruments and methods, silicon compounds, etc., can solve the problems such as the inability to form a gradient stepped pore structure, and the octane number of FCC gasoline is not significantly reduced, and achieve good hydrothermal Stability, large specific surface area, and activity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

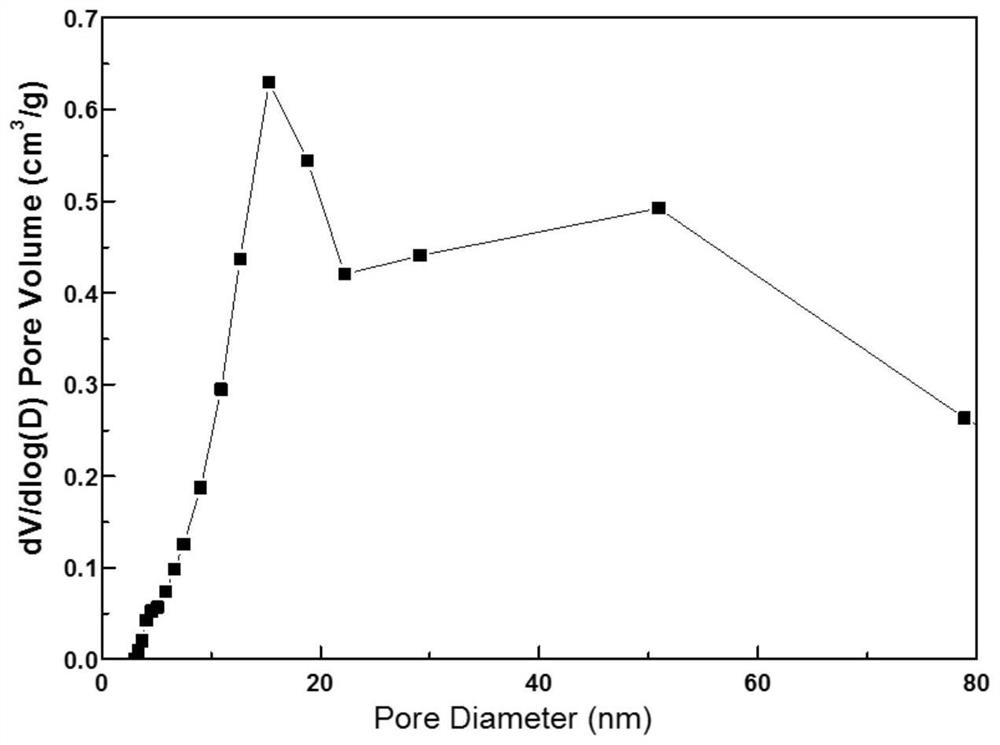

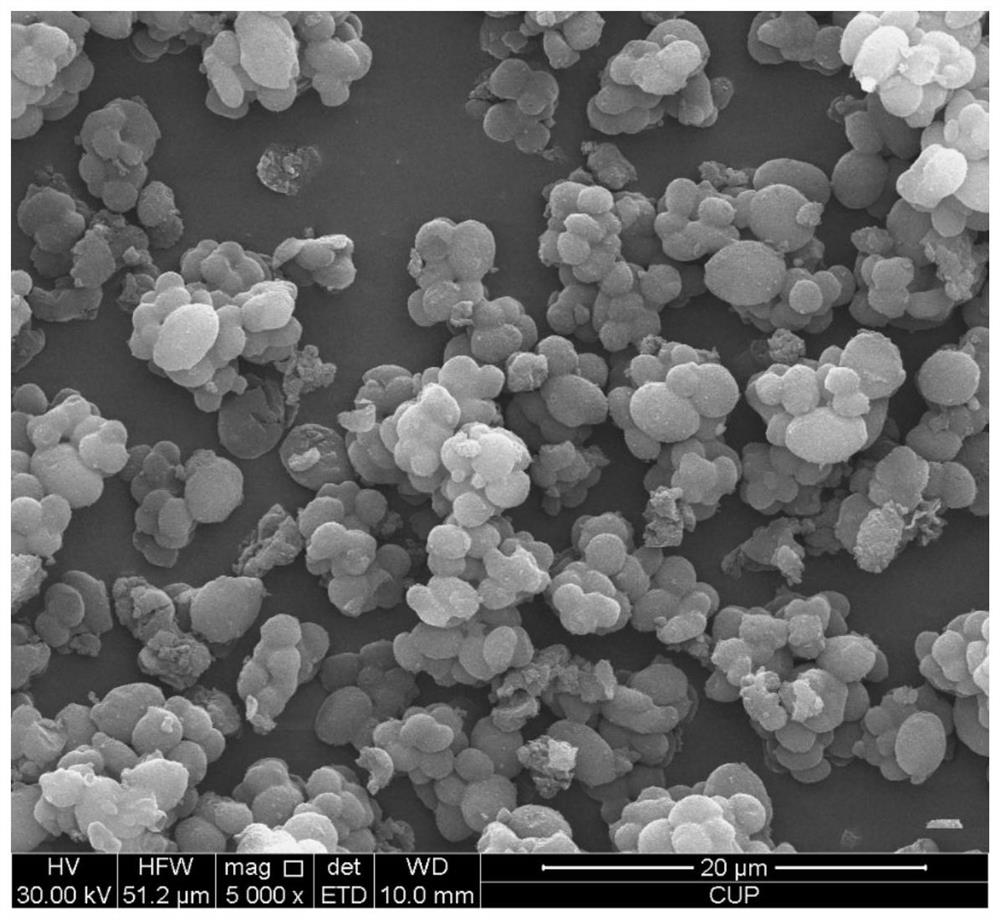

[0026] The invention discloses a method for preparing a composite material with stepped pore structure distribution. It includes the following steps: 1) Mix the template agent F127 or P123 with the corresponding silicon source in an acidic environment and heat and stir until uniform; 2) Evenly add the pore expander dropwise to the mixed solution obtained in 1), stir evenly and then let it stand for a while 3) put the above-mentioned precipitate into a crystallization kettle for crystallization, obtain SBA-15 and MCFs composite material after crystallization, suction filtration, drying, and roasting, and the material has a stepped pore structure. In the present invention, the composite material specific surface area is 400~600m 2 / g, the pore volume is 1.0~2.0cm 3 / g, the pore diameter of 15-20nm accounts for more than 20%, and the pore diameter of 48-53nm accounts for more than 15%.

[0027] The preparation method of the composite material provided by the present invention h...

Embodiment 1

[0037] Preparation of MCFs-SBA-15 composites

[0038] ①Using P123 as the template agent, weigh 40g deionized water, 60g certain concentration of hydrochloric acid and 2g P123 template agent, stir in a water bath at 35°C until a uniform solution is formed;

[0039] ②The pore-enlarging agent mesitylene of 30wt% of the template agent was slowly added dropwise to the homogeneous solution of step ①, and continued stirring in a water bath to obtain a mixed solution;

[0040] ③ Weigh 10wt% tetraethyl orthosilicate (TEOS) as a template agent, slowly add it dropwise to the mixed solution in step ②, and place it in a sealed environment to continue stirring in a water bath, then transfer it to a crystallization tank and place it at 120°C Crystallization in oven for 24h;

[0041] ④ After the crystallization process is over, take out the crystallization kettle for cooling water treatment, filter and wash the product, dry it at 120°C for about 12 hours, and roast it in a muffle furnace at ...

Embodiment 2

[0043] Preparation of MCFs-SBA-15 composites

[0044] ①Using P123 as the template, weigh 40g of deionized water, 60g of hydrochloric acid of a certain concentration and 2g of P123 template, and stir in a water bath at 35°C until a uniform solution is formed;

[0045] ②The pore-enlarging agent mesitylene, which takes 30wt% of the template agent, is slowly added dropwise to the homogeneous solution of step ①, and continues to stir in a water bath to obtain a mixed solution;

[0046] ③ Weigh water glass with 30wt% template agent, slowly add it dropwise to the mixed solution in step ②, and place it in a sealed environment to continue stirring in a water bath, then transfer it to a crystallization kettle and place it in an oven at 120°C for crystallization for 24 hours;

[0047] ④ After the crystallization process is over, take out the crystallization kettle for cooling water treatment, filter and wash the product, dry it at 120°C for about 12 hours, and roast it in a muffle furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com