Intelligent heat treatment device used before cable winding

A heat treatment device and cable technology, which is applied in the direction of thin material processing, transportation and packaging, and delivery of filamentous materials, etc., can solve the problems of poor winding effect and inability to handle cables, and achieve better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

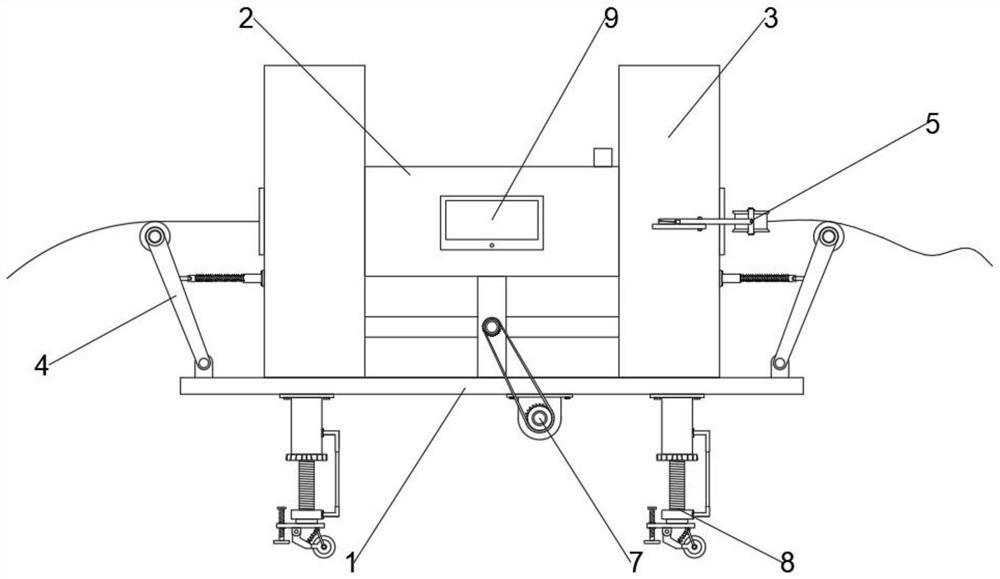

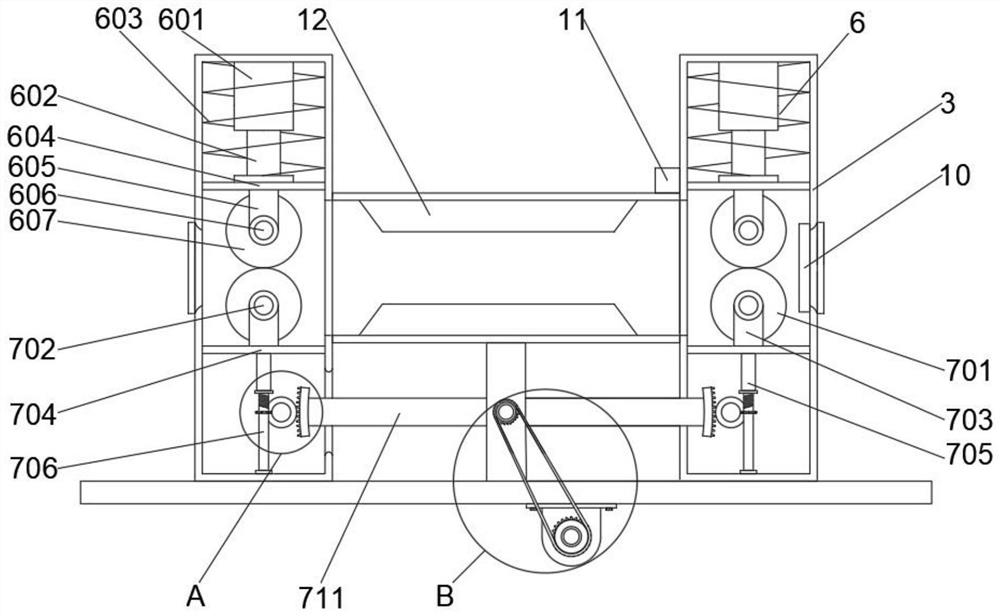

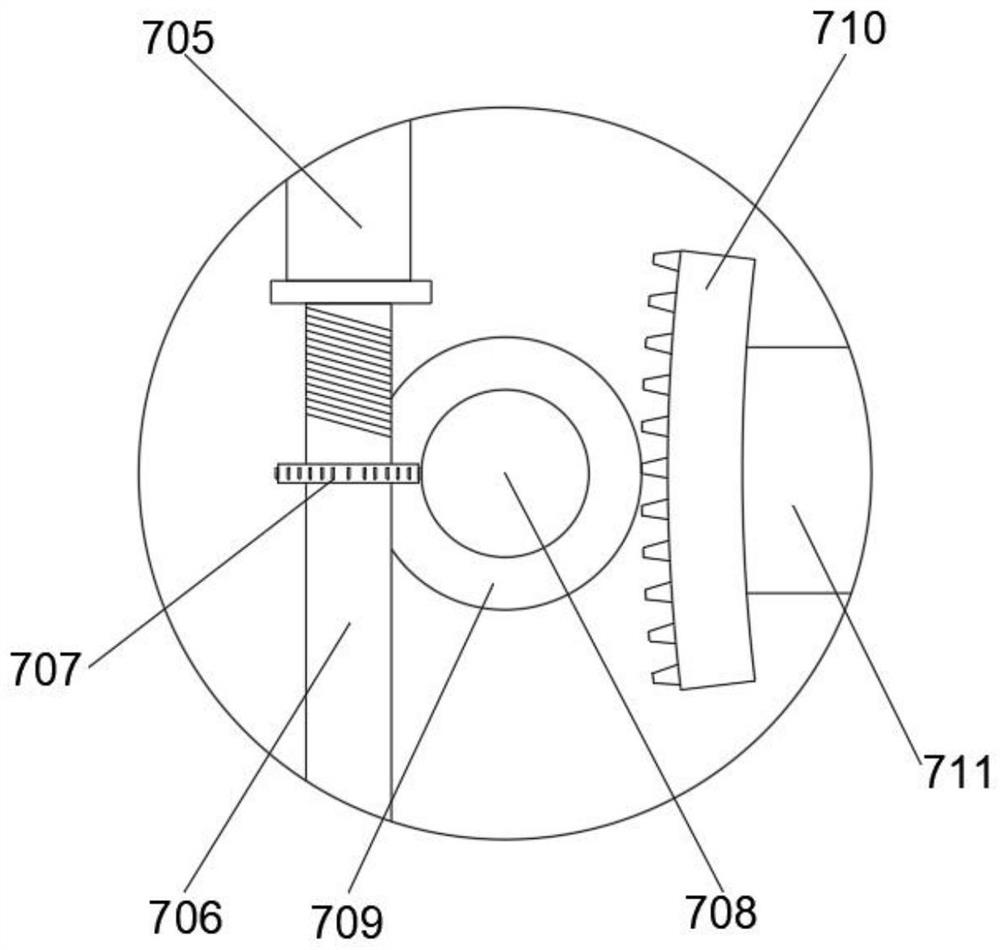

[0030] Such as Figure 1-8 As shown, an intelligent heat treatment device used before cable winding includes a bottom plate 1, a heating pipe 2, a control panel 9, an annular pressure sensor 10, a heater 11 and a heating ring 12, and the control panel 9 is installed on the heating pipe 2 At the outer end, the heater 11 is electrically connected to the heating ring 12, the heating ring 12 is installed in the heating tube 2, the control panel 9 is electrically connected to the annular pressure sensor 10 and the heater 11 respectively, and the two ends of the heating tube 2 are connected through Tension box 3, the tension box 3 is fixedly installed on the top surface of the bottom plate 1, the tension box 3 is installed with a vertical pressure telescopic assembly 6 and a tension adjustment assembly 7, there are two vertical pressure telescopic assemblies 6, and two vertical pressure telescopic assemblies 6 is matched with a tension adjustment assembly 7. A horizontal support ass...

Embodiment 2

[0049] Based on Example 1, when the present invention is adapted to the rewinding device, since the height cannot be adjusted, it cannot adapt to more rewinding devices, and cannot adjust the equipment and the rewinding device to an optimal tension support line.

[0050] Such as figure 1 and 9 As shown, the four corners of the base plate 1 are equipped with a lifting wheel assembly 8, and the lifting wheel assembly 8 includes a shock-absorbing universal wheel 801, a connecting plate 802, a fixed block 808, a lifting screw rod 806 and a sliding cylinder sleeve 805, and the shock-absorbing universal wheel 801 The direction wheel 801 is installed on the bottom end of the connecting plate 802, the top of the connecting plate 802 is connected with the fixed block 808 in rotation, the top of the sliding cylinder liner 805 is fixedly connected with the bottom plate 1 through bolts, and the bottom end of the sliding cylinder liner 805 is rotatably sleeved with threads Rotary sleeve 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com