Labeling device for glass bottles

A glass bottle and labeling technology, applied in labeling, labeling machines, labels, etc., can solve problems such as low productivity and inability to guarantee labeling quality, and achieve the effect of ensuring labeling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A labeling device for glass bottles, such as Figure 1-2 As shown, it includes a base 1, a first support frame 2, a servo motor 3, a second support frame 4, a third support frame 5, a first rotating shaft 6, a collection drum 7, a storage drum 8, and a connecting block 9 , a labeling block 10, a rotating mechanism 11 and a fitting mechanism 12, a first support frame 2 is provided on the front side of the top of the base 1, a servo motor 3 is provided on the top of the first support frame 2, and a second support is provided on the left side of the top of the base 1 frame 4, a third support frame 5 is provided in the middle of the top of the base 1, a first rotating shaft 6 is provided at the output end of the servo motor 3, and a collecting drum 7 and a rotating drum 7 are arranged between the second support frame 4 and the third support frame 5 The material storage drum 8 is connected with the first rotating shaft 6, the second support frame 4 is provided with a connect...

Embodiment 2

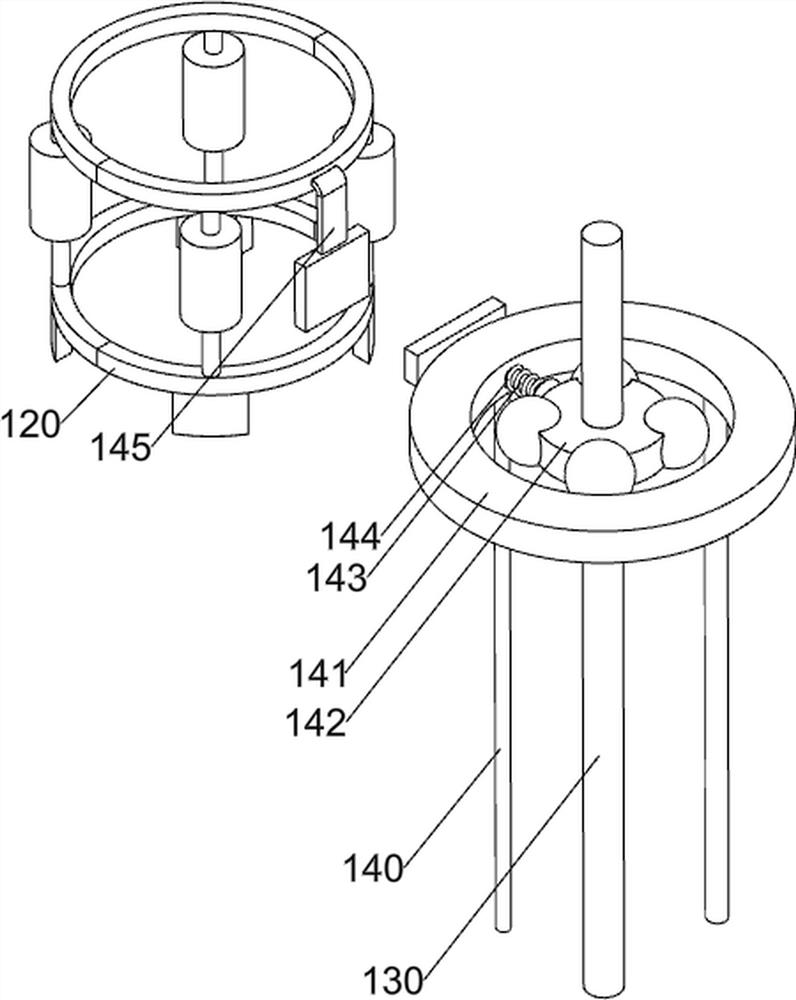

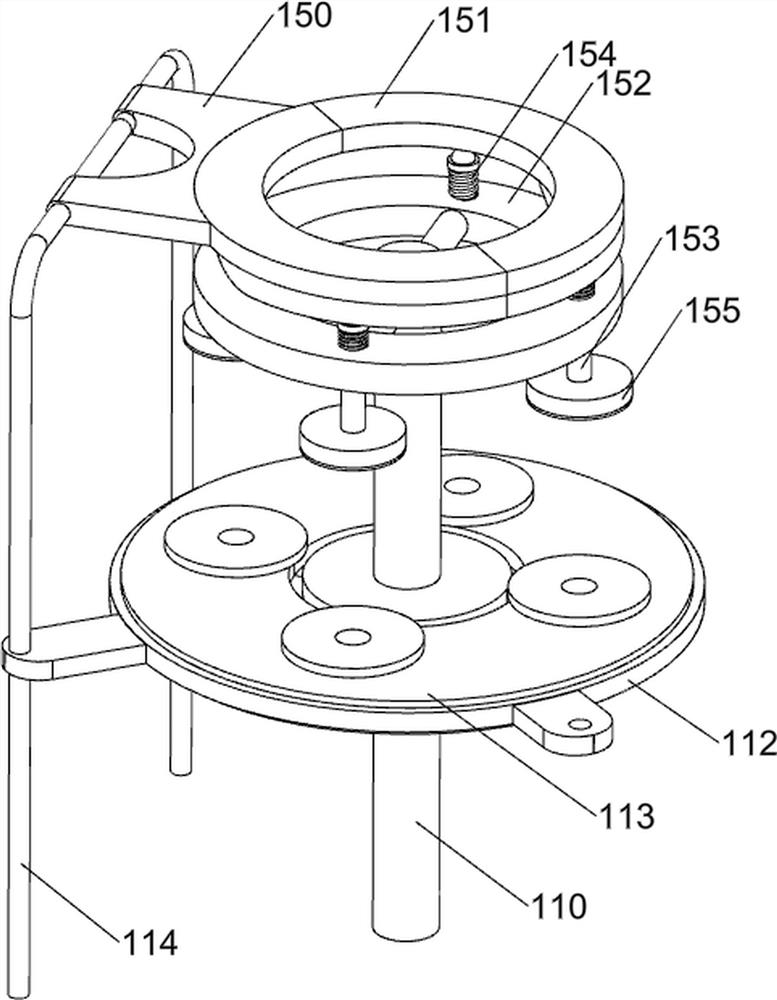

[0081] On the basis of Example 1, such as Figure 3-4 As shown, the rotating mechanism 11 includes a second rotating shaft 110, a first pulley assembly 111, a guide ring 112, a rotating disc 113 and a first support rod 114, and the left side of the base 1 is rotatably provided with a second rotating shaft 110, and the first rotating shaft 6 and the second rotating shaft 110 are provided with a first pulley assembly 111, the first pulley assembly 111 is composed of two pulleys and a belt, the two pulleys are respectively connected on the first rotating shaft 6 and the second rotating shaft 110, and the belt is wound on Between the pulleys, a rotating disk 113 is provided on the second rotating shaft 110, a first support rod 114 is provided on the left rear side of the top of the base 1, a guide ring 112 is provided on the first support rod 114, and the guide ring 112 and the rotating disk 113 slide connect.

[0082] The bonding mechanism 12 includes a first connecting frame 12...

Embodiment 3

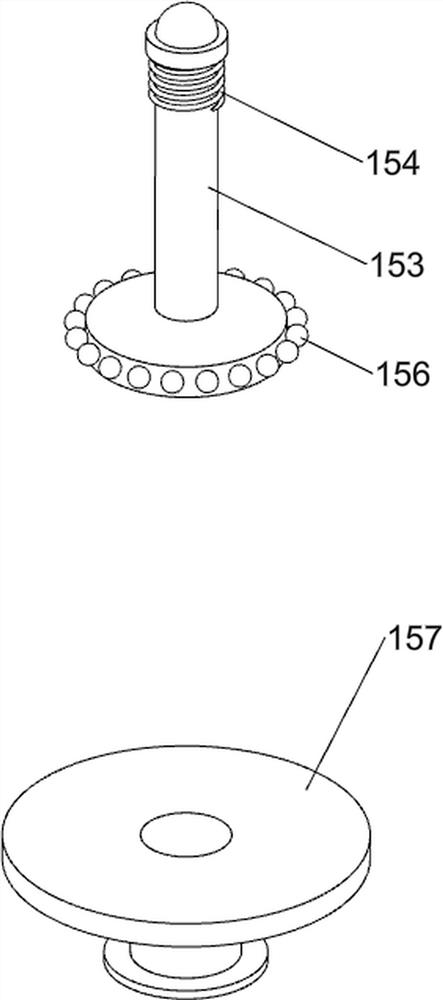

[0085] On the basis of Example 2, such as Figure 5-9 As shown, a feeding mechanism 13 is also included, and the feeding mechanism 13 includes a third rotating shaft 130, a second pulley assembly 131, a support plate 132, a distribution tray 133, a second connecting frame 134, a first limiting plate 135, a fourth Rotating shaft 136, the fifth rotating shaft 137, the third pulley assembly 138, bevel gear 139, limit frame 1310 and conveyor belt 1311, the middle rotating type of base 1 top is provided with the third rotating shaft 130, between the third rotating shaft 130 and the second rotating shaft 110 A second pulley assembly 131 is provided. The second pulley assembly 131 is composed of two pulleys and a belt. The two pulleys are respectively connected to the third rotating shaft 130 and the second rotating shaft 110. The belt is wound between the pulleys. The top of the base 1 is symmetrical Four support plates 132 are provided, and a fourth rotating shaft 136 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com