Bidirectional oil pressure inner blind hole tool bit

A technology of internal blind hole and cutter head, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems of high failure rate, slow retraction of internal blind hole cutter rod, etc., and achieve Avoid breakage, simple structure, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

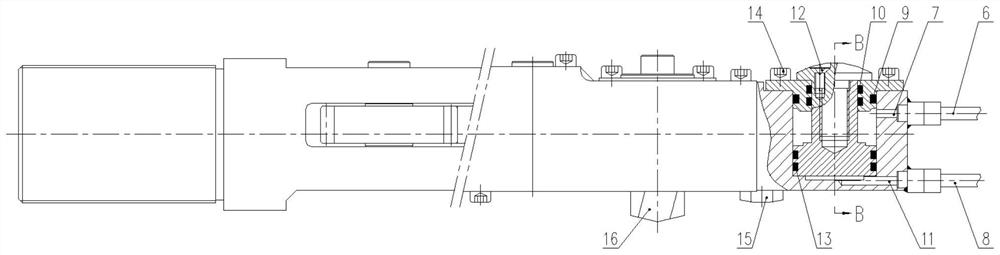

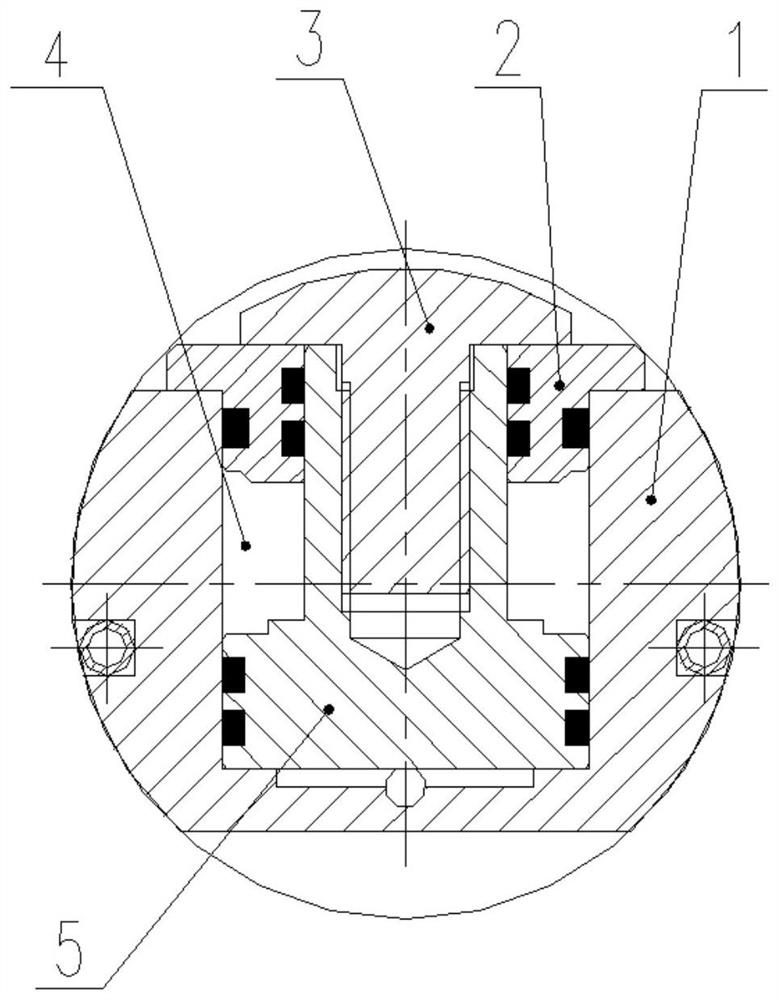

[0012] refer to figure 1 and figure 2 , a two-way hydraulic internal blind hole cutter head, including a cutter head 1, and also includes a small cutter block 16, a limit bolt 15, a piston 5, a piston cap 3 and a gland 2, and the cutter head 1 is opened There is a piston cavity 4, and the end face of the cutter head is provided with an upper hydraulic channel 7 and a lower hydraulic channel 11 communicating with the piston cavity 5, and the upper hydraulic channel 7 and the lower hydraulic channel 11 are respectively connected with the upper copper oil pipe 6 and the lower copper oil pipe 8, The upper copper oil pipe 6 and the lower copper oil pipe 8 are connected to the reversing valve body; the gland 2 is set on the piston 5 and sealed by the first sealing ring 10; the piston cap 3 is installed on the piston 5 and passed through the sink The head screw 12 is fixed, the piston 5 is installed in the piston chamber hole 4, the piston 5 and the gland 2 and the piston chamber h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com