Position control part and plunger

A technology for controlling components and plungers, which is applied to components of pumping devices for elastic fluids, variable displacement pump components, wellbore/well components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

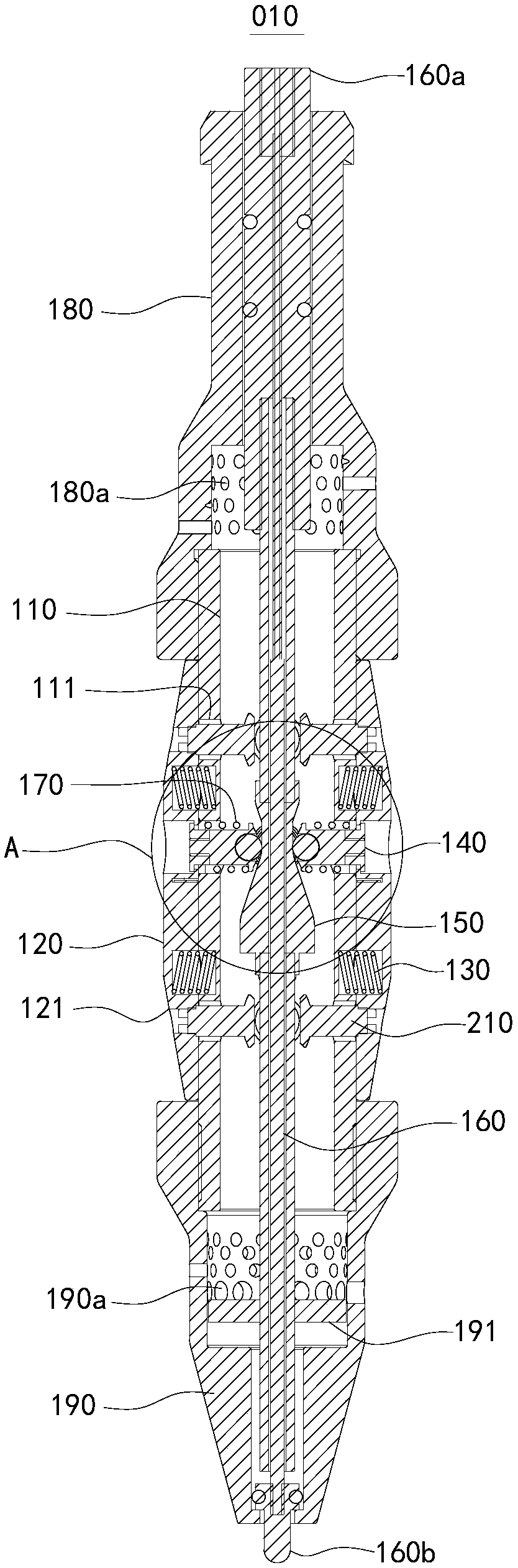

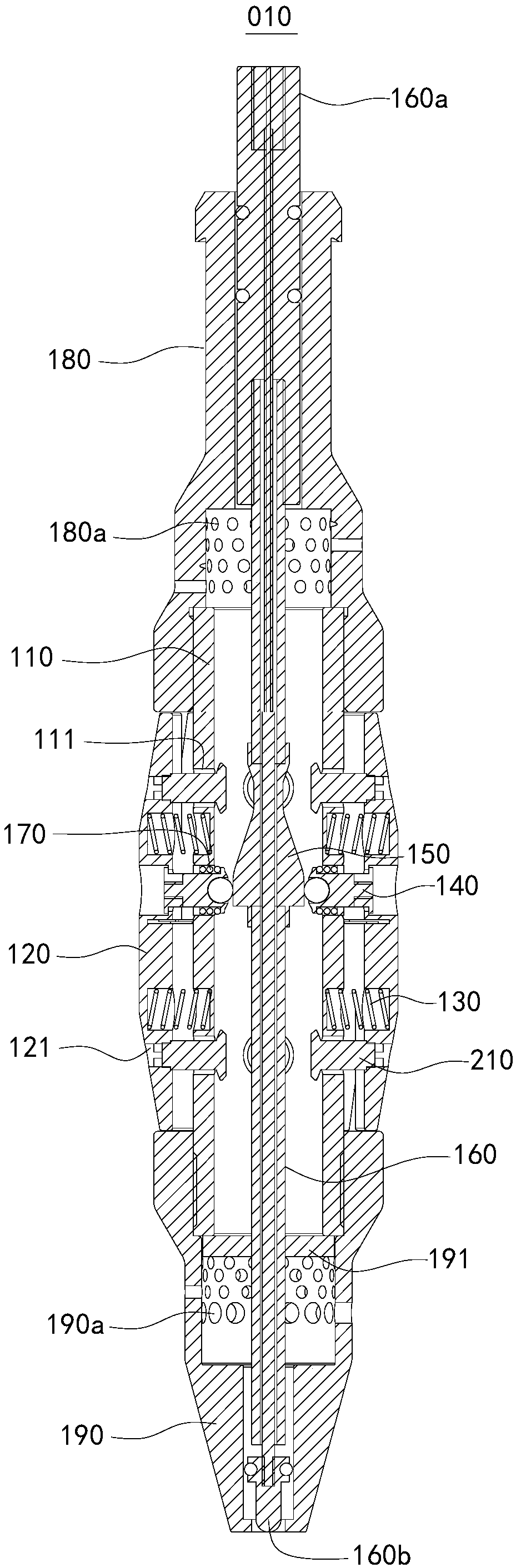

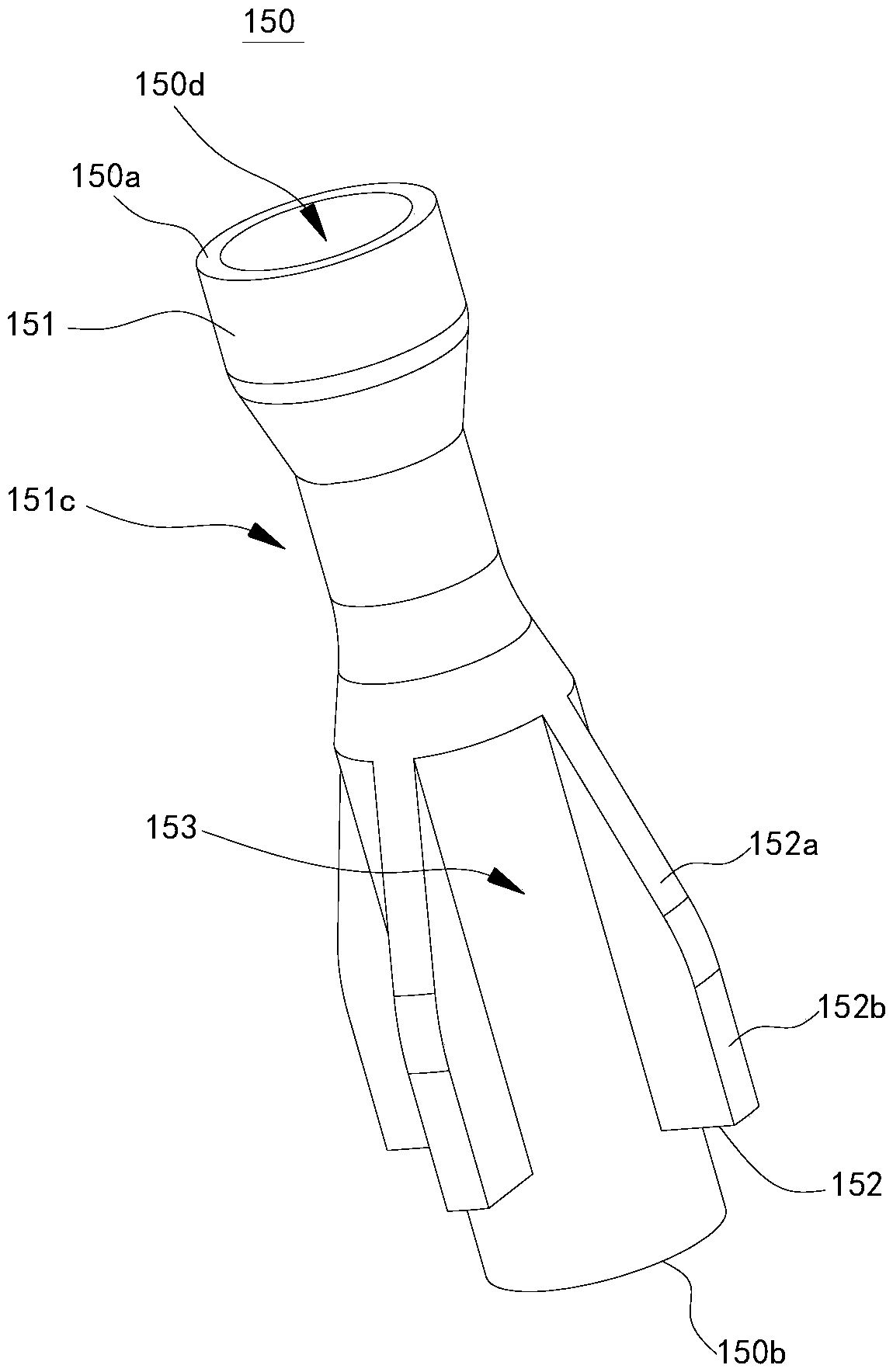

[0032] Please refer to figure 1 and figure 2 , this embodiment provides a plunger 010. The plunger 010 includes a core tube 110 , a packing piece 120 , a first elastic reset member 130 , a linkage member 140 , a position control component 150 , a driving mechanism 160 , a second elastic reset member 170 , an upper plug 180 and a lower plug 190 .

[0033]The core pipe 110 is a circular tube, and the upper plug 180 and the lower plug 190 are also circular tubes. The upper plug 180 and the lower plug 190 are screwed to the upper and lower ends of the core tube 110 respectively. A plurality of upper flow holes 180 a communicating with the inner space of the core tube 110 are opened on the periphery of the upper plug 180 . The periphery of the lower plug 190 defines a plurality of lower through holes 190a communicating with the inner space of the core tube 110 . Fluid can enter the core tube 110 through the lower through hole 190a, and flow out of the core tube 110 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com