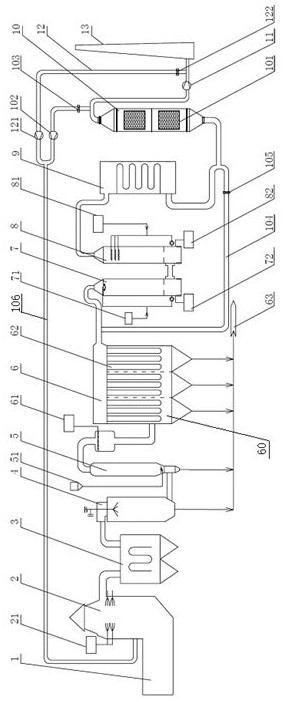

Multi-pollutant collaborative advanced treatment system for hazardous waste incineration flue gas

A technology for incinerating flue gas and hazardous waste, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of large footprint, shortened service life of catalysts, high emission requirements, etc., achieve safe and reliable operation costs, and reduce NOx The effect of generating and reducing the flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Hazardous waste is incinerated in the rotary kiln 1, and when the high-temperature flue gas produced enters the secondary combustion chamber 2, ammonia water is injected into the flue gas through the SNCR denitrification device 21 as a denitrification reducing agent, so that the NOx in the flue gas is at 850-1150°C In the temperature window, there is a reduction reaction with ammonia water, and the flue gas after denitrification enters the waste heat boiler 3 for waste heat recovery and cooling. The 550-600°C flue gas discharged from the flue gas outlet of the waste heat boiler 3 enters the quenching tower 4 and cools down to 300°C within 1 second in the quenching tower. Slaked lime is sprayed in the gas as a deacidification agent to remove part of the acid gas. The unreacted deacidification agent is discharged out of the dry deacidification system 5 synchronously with the flue gas, and is synchronized with the ammonia reducing agent sprayed through the ammonia injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com