Shirt collar drawing and water-absorbing process

A collar and craftsmanship technology, applied in the field of shirt collar production, can solve the problems of not conforming to the curvature of the neck, poor three-dimensional shape of the finished product, and not round and smooth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

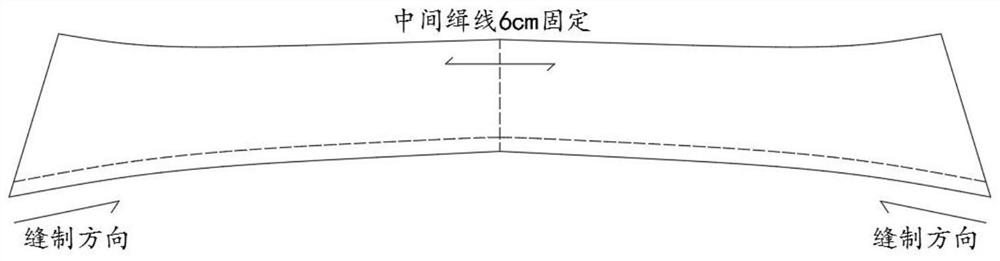

[0030] Such as figure 1 As shown, a kind of shirt collar returning draft draft process that one embodiment of the present invention proposes comprises the following steps:

[0031] S1. Horizontal cutting of the non-stick lining in the collar seat: when cutting, the inner ring size of the collar seat is smaller than the outer ring size, and the horizontal cutting is carried out to improve the elasticity of the inner collar seat so that it can be stretched and make the inner layer of the collar seat more flat; When lining, the interlining should be placed on the opposite side of the collar seat. After the comparison sample has no deformation, the interlining is fixed by vertical pressing with an iron to complete the setting of the bottom collar lining; the non-stick lining in the collar seat can make the inner non-stick lining more In order to be soft and comfortable, it is cut to make it more elastic, which further improves the comfort of the collar seat against the neck;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com