Preparation method of ternary positive electrode material with low residual alkali content and high capacity retention ratio

A cathode material, high-capacity technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of limited large-scale application, high nickel material rate and cycle performance decline, capacity attenuation, etc., to simplify the cathode calcination process, improve Circulation retention rate, the effect of reducing excess moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

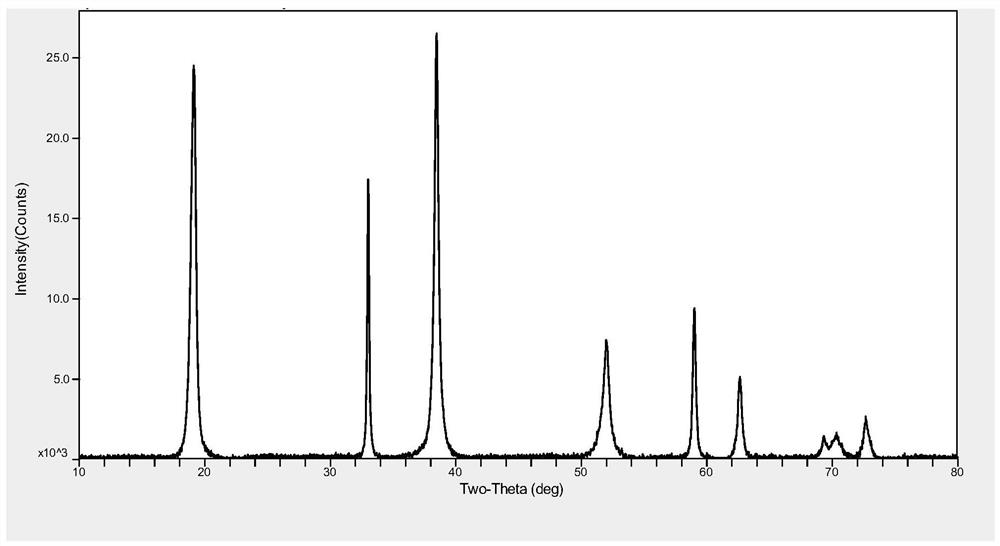

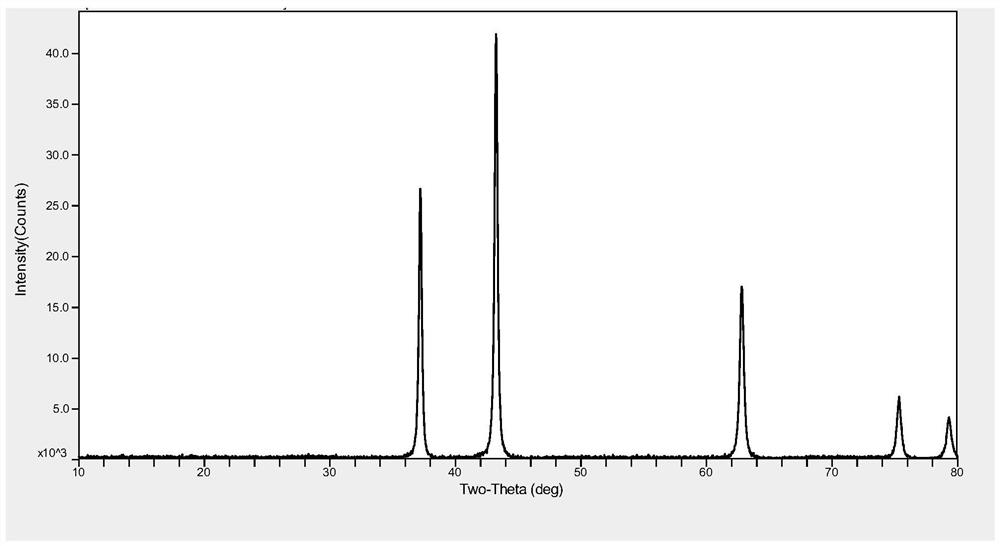

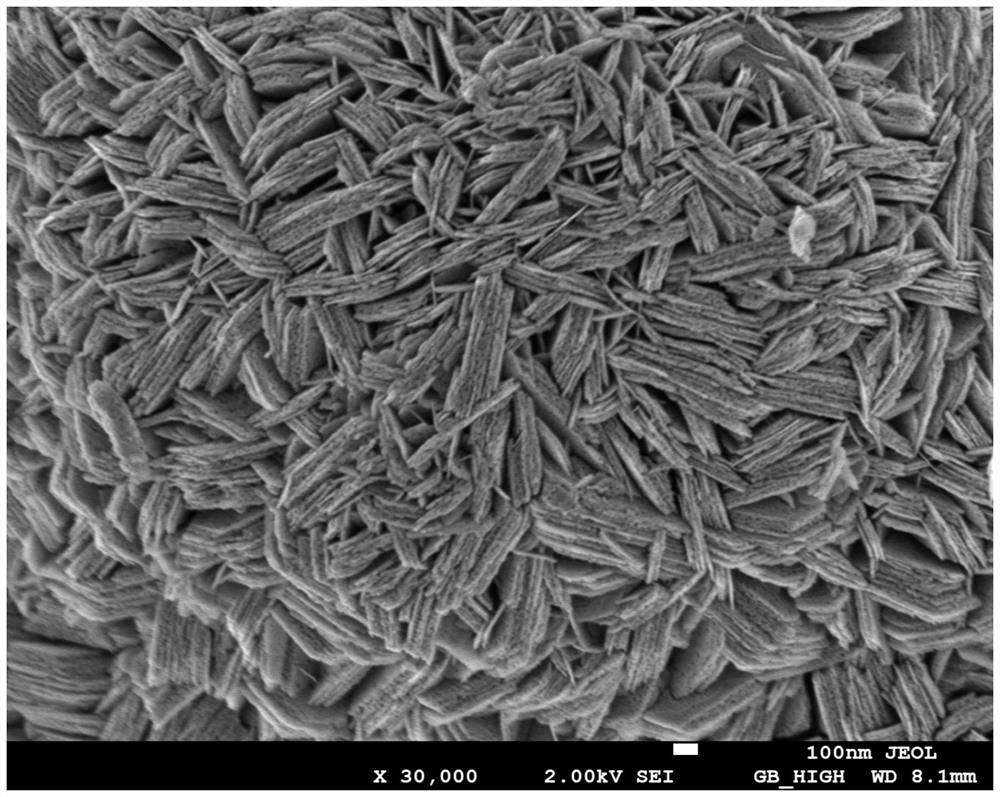

Image

Examples

Embodiment 1

[0047]Step 1. Dehydrate the nickel-cobalt-manganese hydroxide precursor with a metal element ratio of 85:05:10 after synthesis until the water content is 13%;

[0048] Step 2. Dry the nickel-cobalt-manganese hydroxide precursor with 13% moisture and metal element ratio of 85:05:10 at 180°C, measure the half-peak width, and obtain the process product;

[0049] Step 3. The process product obtained in step 2 is calcined at 300°C, 450°C, and 600°C for 30 minutes respectively, and washed and dried to obtain a ternary precursor;

[0050] Step 4. Mix the ternary precursor obtained in step 3 with lithium hydroxide according to the lithium ratio of 1.05, and sinter in the same process as in Comparative Example 1 to obtain a ternary positive electrode material.

Embodiment 2

[0052] Step 1. Dehydrate the nickel-cobalt-manganese hydroxide precursor with a metal element ratio of 85:05:10 after synthesis until the water content is 13%;

[0053] Step 2. Dry the nickel-cobalt-manganese hydroxide precursor with a water content of 13% and a metal element ratio of 85:05:10 at 180°C, measure the half-peak width, and soak in a mixed solution of ammonia water and ammonium nitrate for 1 hour , and then centrifugally washed and dried at 180°C to obtain the process product;

[0054] Step 3. Calcining the process product obtained in Step 2 at 300° C., 450° C., and 600° C. for 30 minutes respectively, washing and drying with water to obtain a ternary precursor.

[0055] Step 4. Mix the ternary precursor obtained in step 3 with lithium hydroxide according to the lithium ratio of 1.05, and sinter in the same process as in Comparative Example 1 to obtain a ternary positive electrode material.

Embodiment 3

[0057] Step 1. Dehydrate the nickel-cobalt-manganese hydroxide precursor with a metal element ratio of 96:02:02 after synthesis until the water content is 12%;

[0058] Step 2. Dry the nickel-cobalt-manganese hydroxide precursor with 12% moisture and metal element ratio of 96:02:02 at 180°C, and measure the half-peak width in a mixed solution of sodium carbonate and sodium hydroxide Soak for 2 hours, then perform centrifugal washing, and dry at 180°C to obtain the process product;

[0059] Step 3. Calcining the process product obtained in step 2 at 300°C, 450°C, and 600°C for 30 minutes respectively, washing and drying with water to obtain a ternary precursor;

[0060] Step 4. Mix the ternary precursor obtained in step 3 with lithium hydroxide according to the lithium ratio of 1.05, and sinter in the same process as in Comparative Example 1 to obtain a ternary positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com