Acid-resistant rubber composition and application thereof, vulcanized rubber and preparation method and application thereof

A rubber composition and composition technology, applied in the field of rubber, can solve the problems of low mechanical strength and high acid resistance performance that cannot meet the requirements, and achieve the effects of good mechanical performance, excellent acid resistance performance and high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

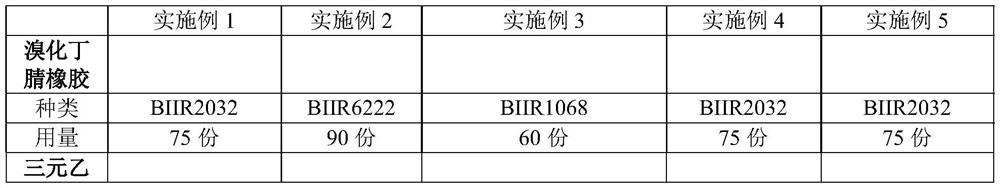

[0082] The composition formula of this embodiment is shown in Table 2.

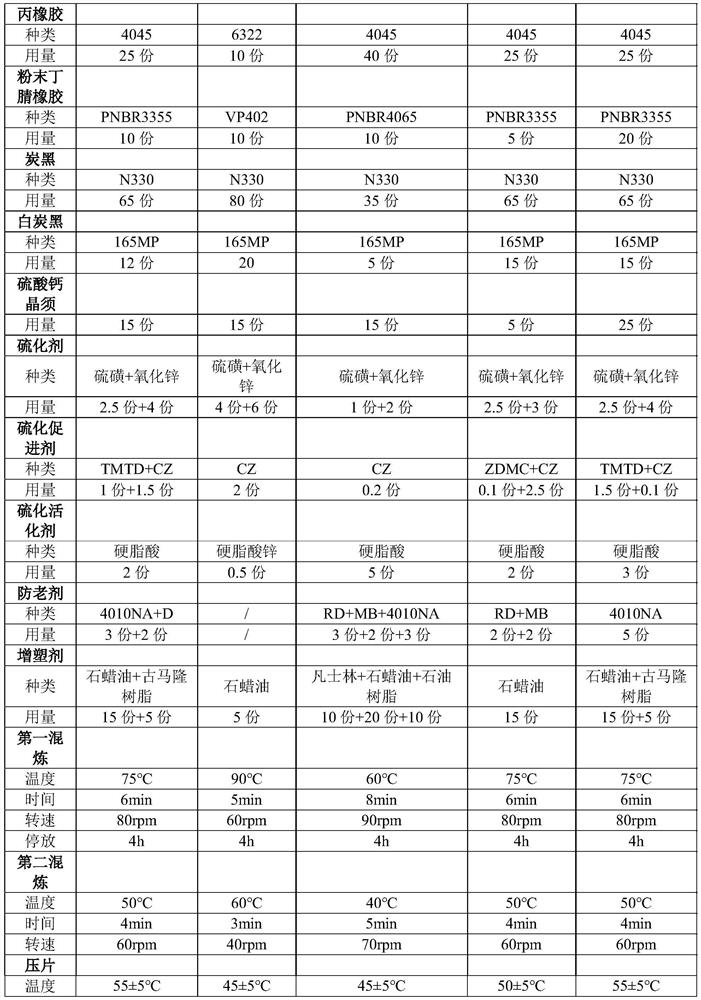

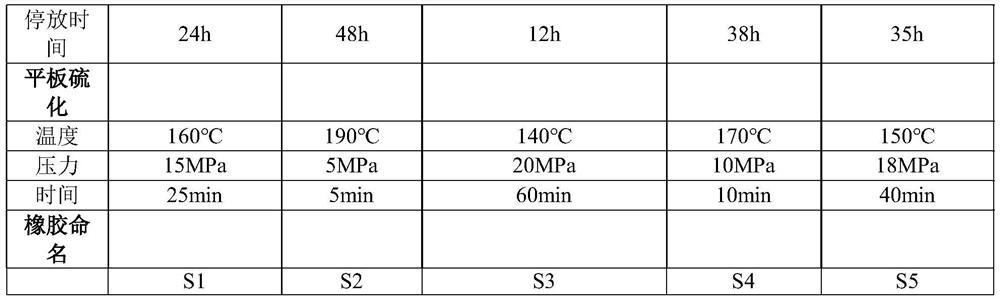

[0083] The preparation method of vulcanized rubber is as follows:

[0084] First mixing:

[0085] Set the initial temperature of the internal mixer to 75°C and the rotational speed to 80rpm, and add the rubber matrix, EPDM rubber, powdered nitrile rubber, reinforcing agent, calcium sulfate whiskers, vulcanization activator, anti-aging agent and plasticizer to the internal mixing Carry out the first mixing in the machine for 6 minutes, deglue, and park for 4 hours to obtain the masterbatch.

[0086] Second mixing:

[0087] Set the initial temperature of the internal mixer to 50°C and the rotational speed to 60 rpm, put the masterbatch, vulcanizing agent and vulcanization accelerator into the internal mixer, mix for 4 minutes, and discharge the rubber.

[0088] Pass the rubber compound obtained by the above method once on the open mill (that is, tableting) with a roller distance of 0.5mm and a roller tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com