Prestressed raft foundation construction method

A technology of raft foundation and construction method, which is applied in basic structure engineering, construction, etc., can solve problems affecting the bearing capacity of raft foundation, large concrete volume, and easy occurrence of heat of hydration, etc., and achieve high concrete density and mechanical strength. Good performance, good water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

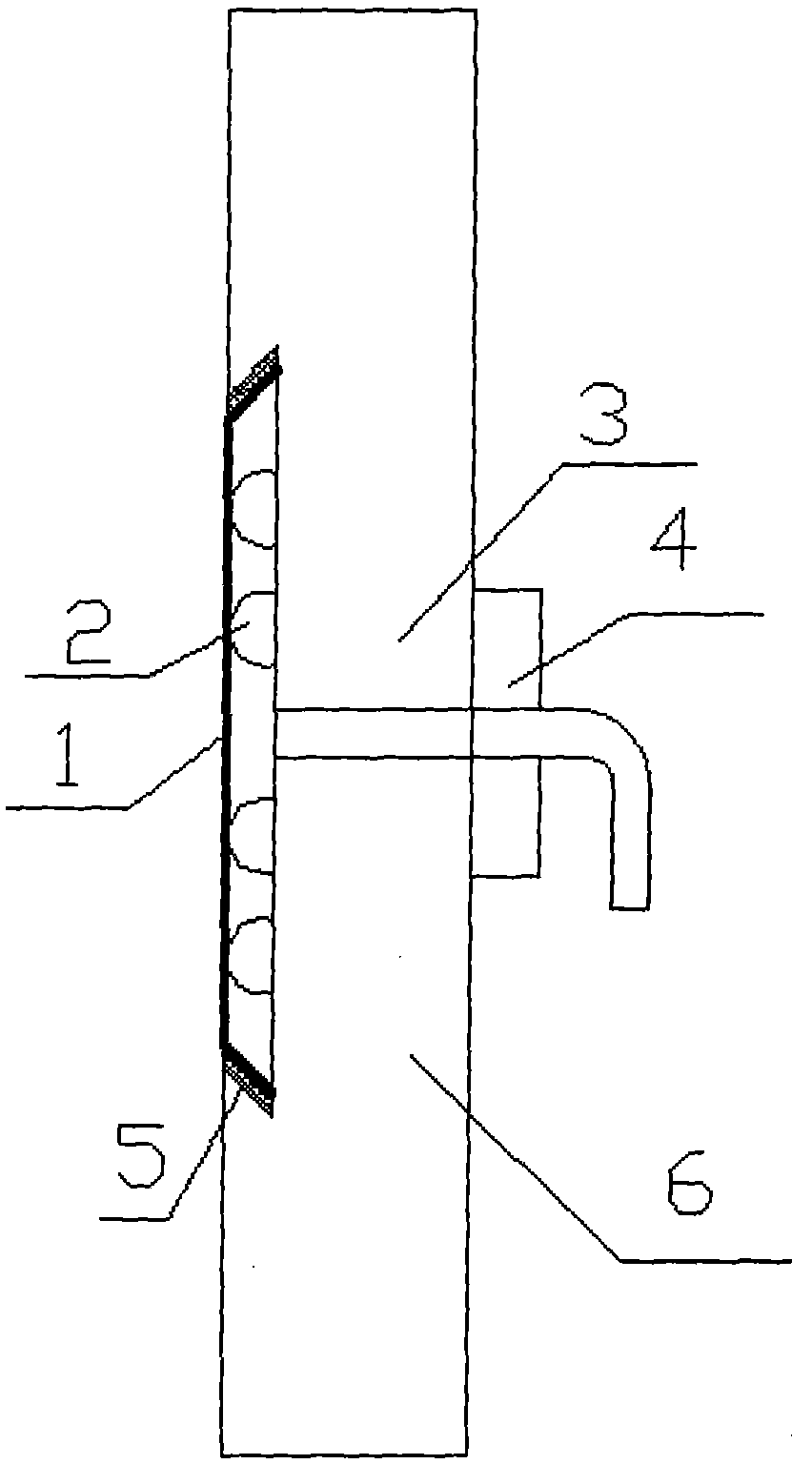

[0032] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0033] The raft foundation thickness of a project is 1.2m, and the raft foundation area is 820M 2 , is a fourteen-story frame structure building.

[0034] The construction steps of this embodiment include:

[0035] (1) Ingredients

[0036] Raft slab foundation concrete is tested according to the traditional mix ratio, and then adjusted according to the characteristics of vacuum concrete. The specific use is as follows: the amount of cement is 8% to 10% lower than that of traditional cement, and the sand rate is 5% higher than that of traditional sand. Water: 175kg, cement: 398kg, sand: 566kg, gravel: 1261kg. Water: 175kg, cement: 362kg, sand: 594kg, gravel: 1261kg. The slump value was 9 cm.

[0037] (2) Binding steel bars

[0038] Before the reinforcement is bound, the reinforcement location line should be popped up to ensure that the location of the reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com