Ship propeller protection component

A technology for protecting components and propellers, which is applied to ship propulsion, ship parts, propulsion parts, etc. It can solve the problems of inconvenient use and inability to deal with sundries in the protective cover, and achieve the effect of avoiding entanglement of sundries and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0023] The embodiments of the present invention will be described below according to the overall structure of the present invention.

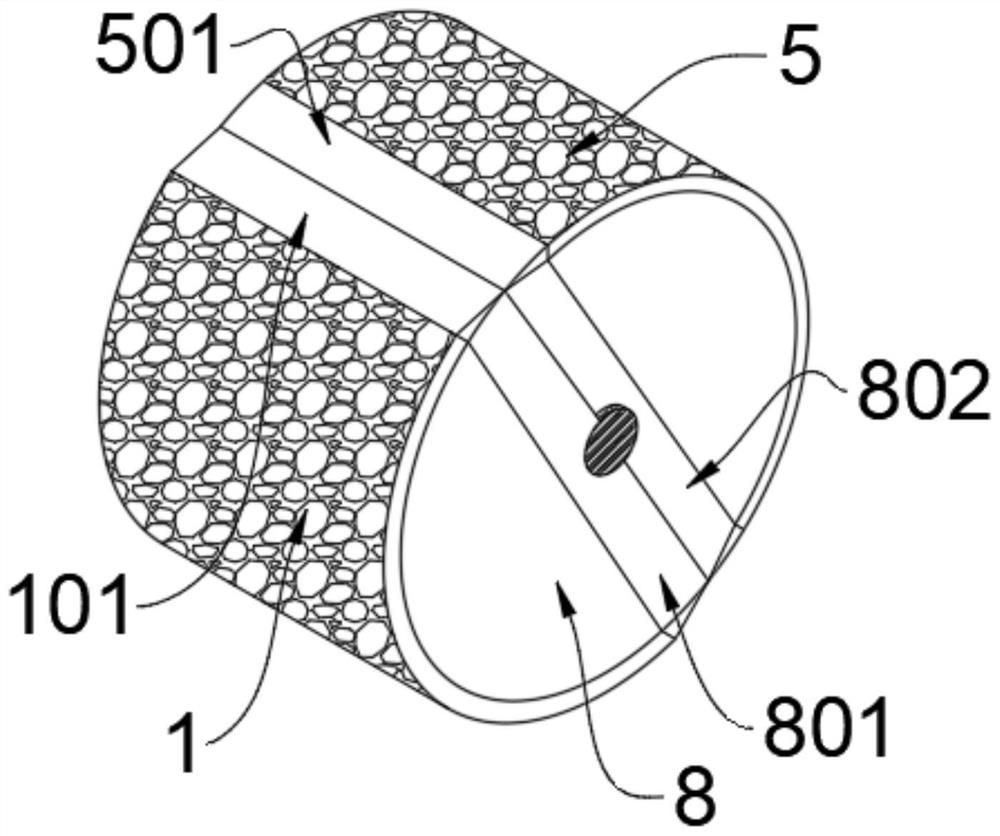

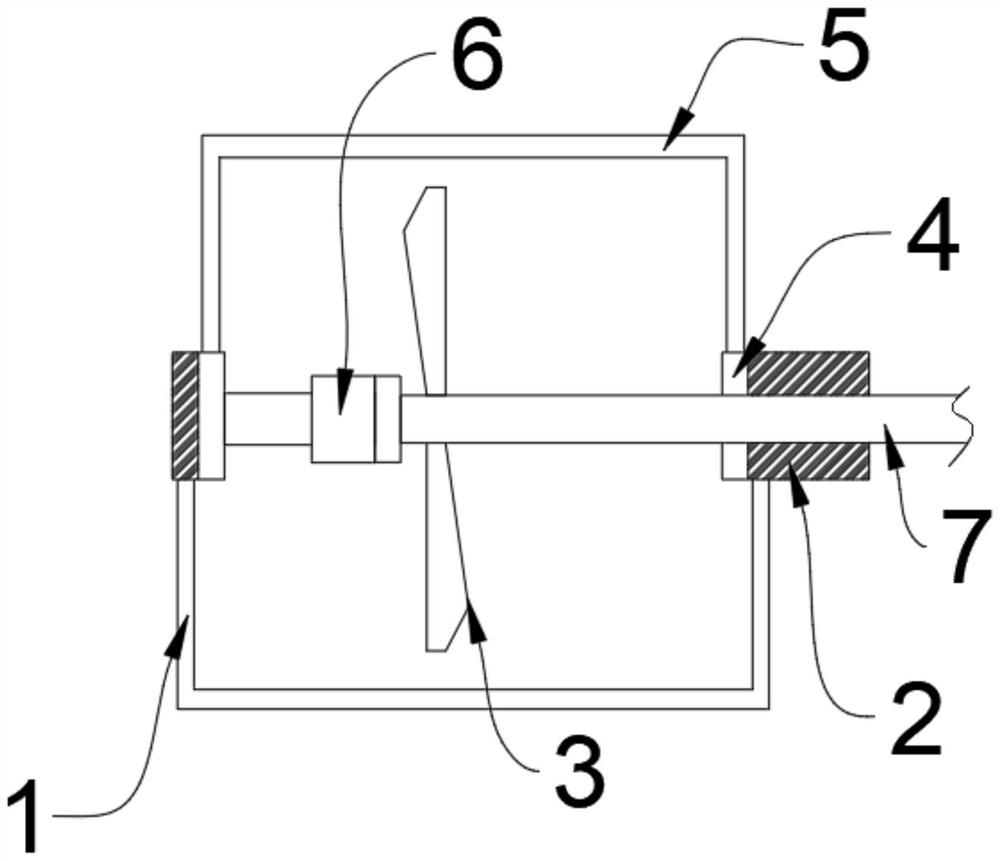

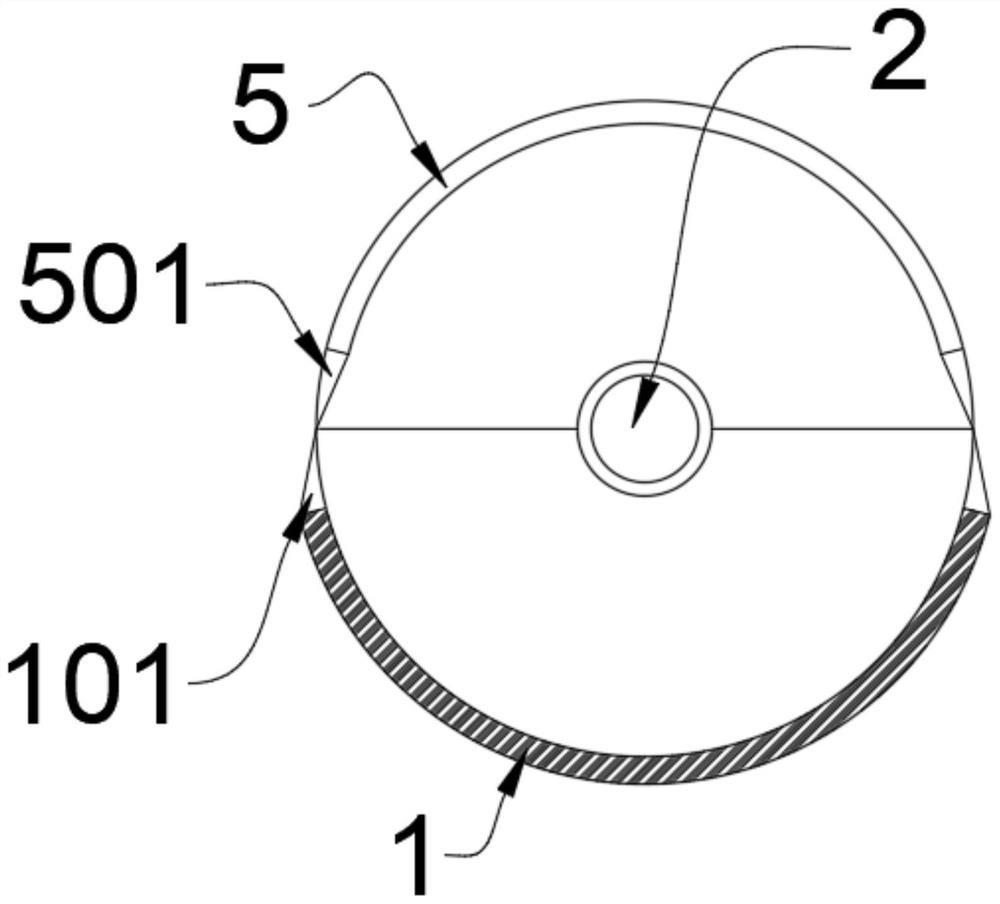

[0024] A ship propeller protection component, such as Figure 1-4 As shown, the main body of the protective part 1 and the mounting seat 2 are included, the first cutting blade 101 is fixed on both sides of the main body of the protective part 1, the main body of the protective part 1 is fixedly installed on the mounting seat 2, and one end of the mounting seat 2 is movably installed with a rotating shaft 4. A cutting part 5 is fixed on the outer surface of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com