Manipulator assembling equipment for automatically assembling materials

An assembly equipment and automatic assembly technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of single assembly structure, limited assembly stroke, poor equipment accuracy, etc., and achieve the effect of precise positioning assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0031] This embodiment is an embodiment of a manipulator assembly device for automatic material assembly.

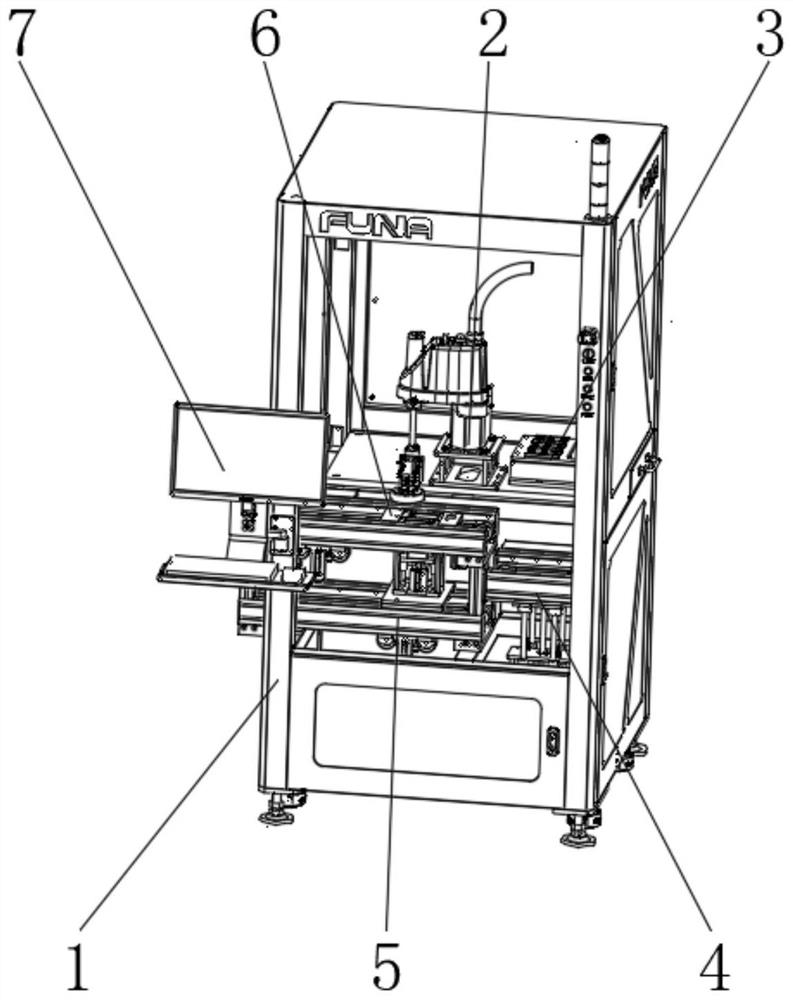

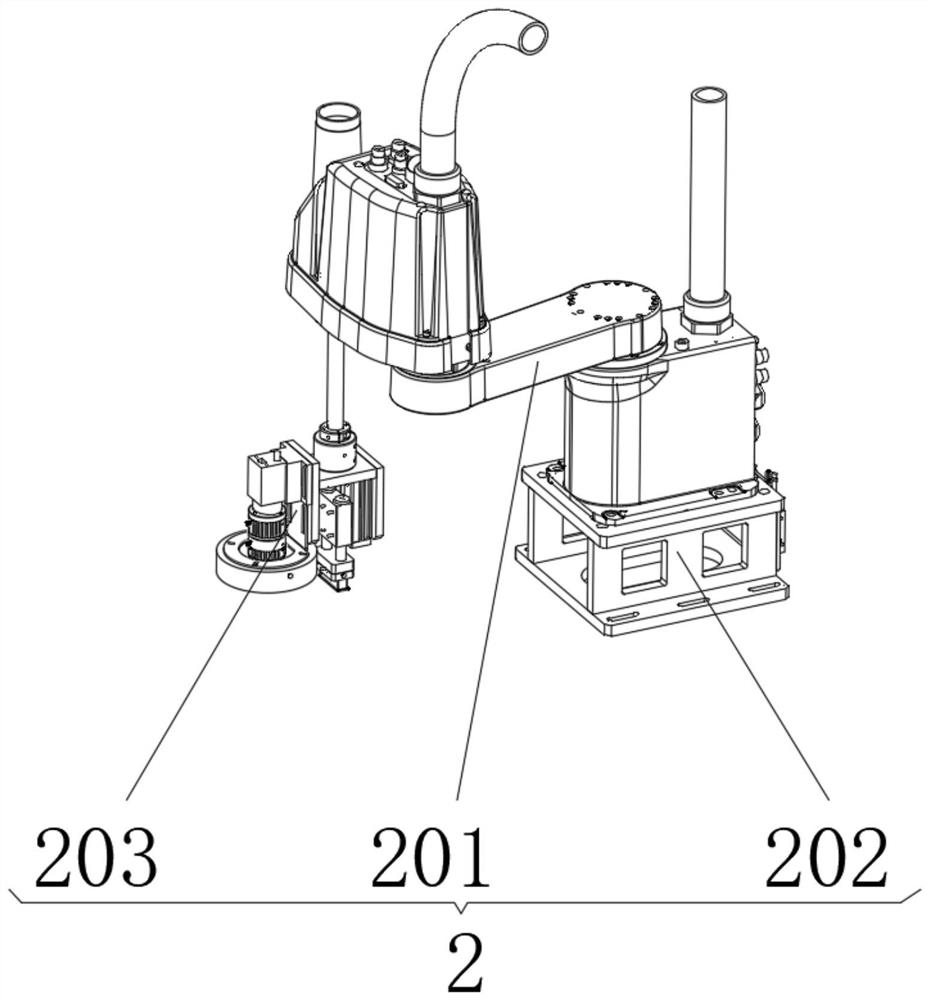

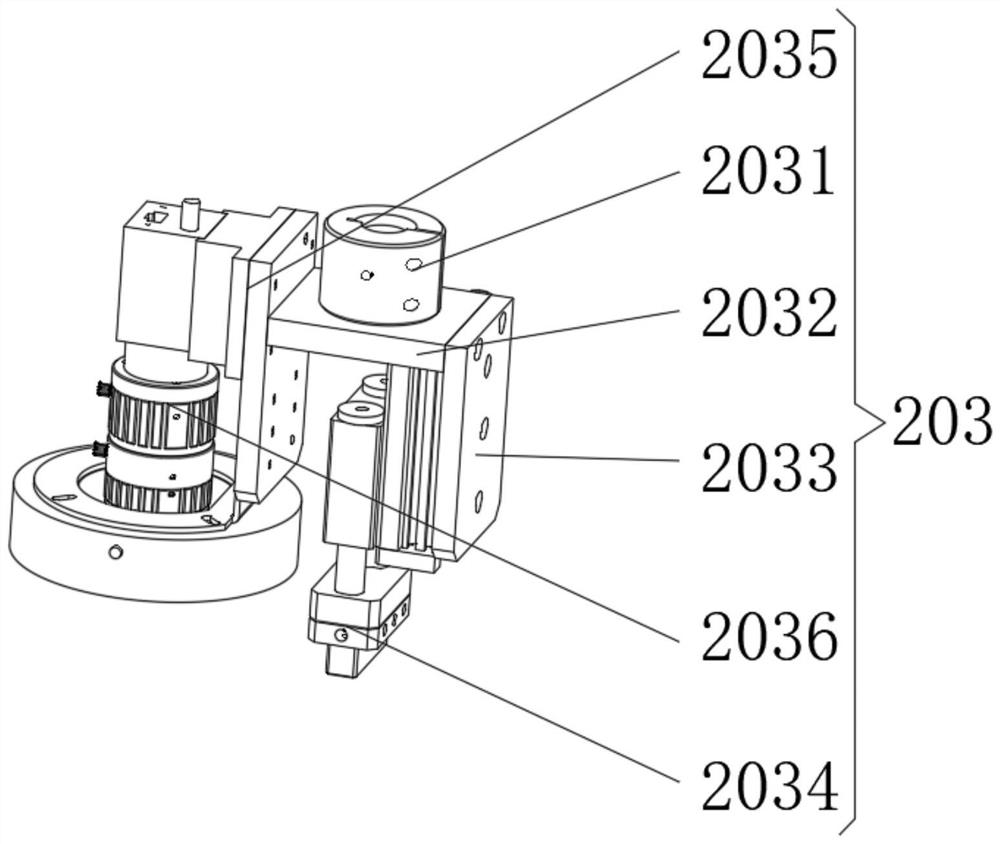

[0032] Such as Figure 1-7 As shown, a manipulator assembly equipment for automatic assembly of materials includes an equipment support frame body 1, an assembly mechanism 2 is fixedly installed on the rear side of the top outer wall of the equipment support frame body 1, and the right rear side of the top outer wall of the equipment support frame body 1 A manual sliding table material box mechanism 3 is fixedly installed, a material tray transfer mechanism 4 is fixedly installed on the right front side of the top outer wall of the equipment support frame body 1, and a belt line assembly mechanism 5 is fixedly installed on the left front side of the top outer wall of the equipment support frame body 1, A material tray 6 is arranged on the top outer wall of the belt line assembly mechanism 5, and a controller 7 is fixedly installed on the left side of the front outer wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com