Fault early warning method and fault early warning device for speed-changing gear box

A fault warning, gearbox technology, applied in prediction, alarm, character and pattern recognition, etc., can solve problems such as user inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Embodiments of the present application provide a fault pre-warning method and a fault pre-warning device for a gear box, which are used for early warning of a gear box fault.

[0089] Gearboxes are widely used in the field of thermal power generation. However, the working conditions of the gear box are complex, and the process of bearings and gears from early abnormality to functional failure is a gradual deterioration process, and there is a serious time lag and passive response. The fault early warning method in the embodiment of the present application is now provided to solve the problem.

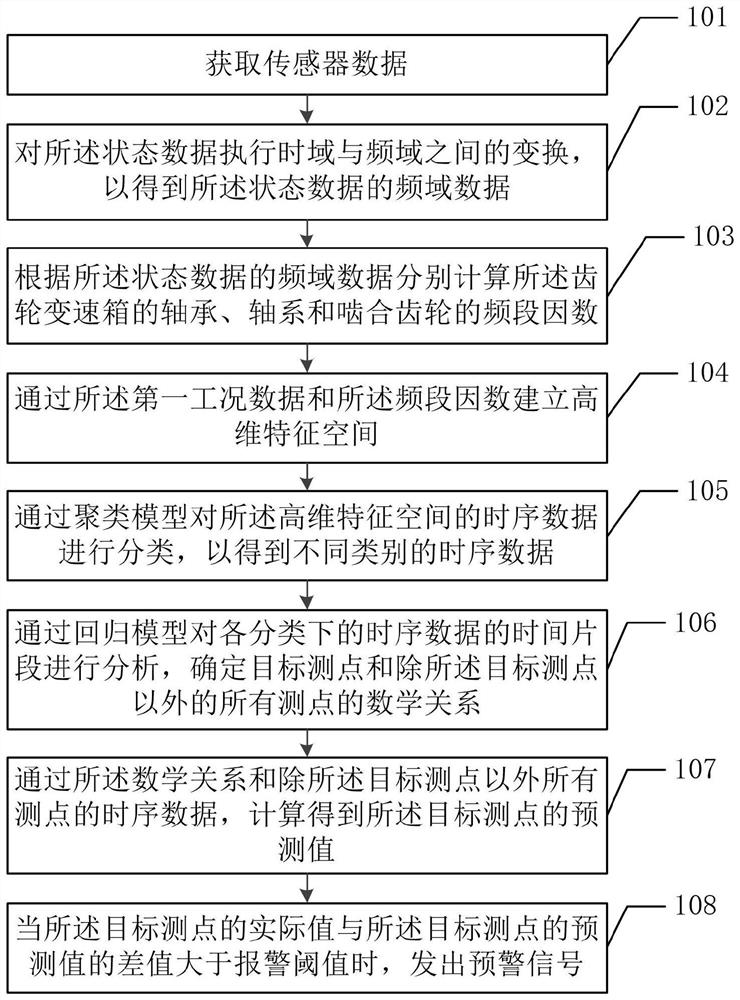

[0090] see figure 1 One embodiment of the fault warning method in the embodiment of the present application includes:

[0091] 101. Obtain sensor data;

[0092] Acquire sensor data from surveillance information systems, distributed control systems, rotating machinery monitoring and management systems, etc. The sensor data includes first working condition data and status data,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com