A multi-component waste gas online monitor

A monitor and multi-component technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of the efficiency of exhaust gas detection and other issues, achieve the effect of reducing errors, shortening the use gap, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

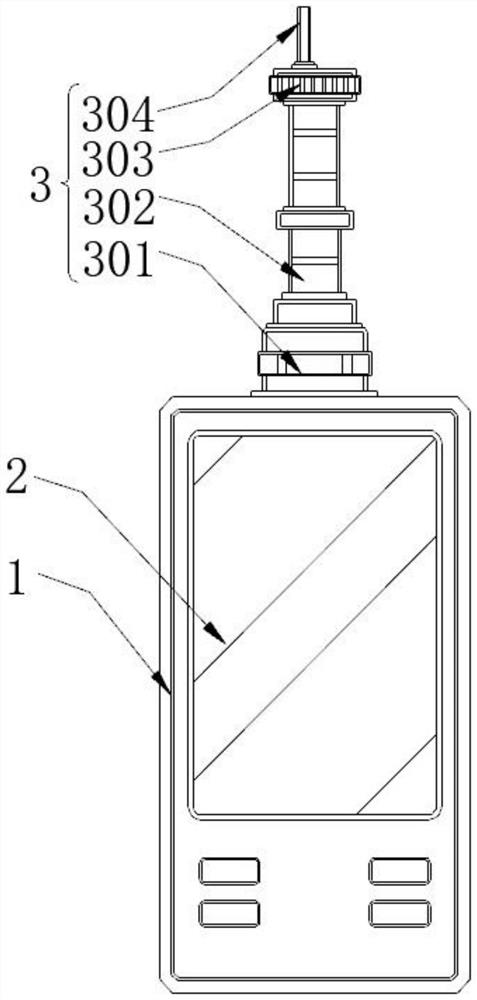

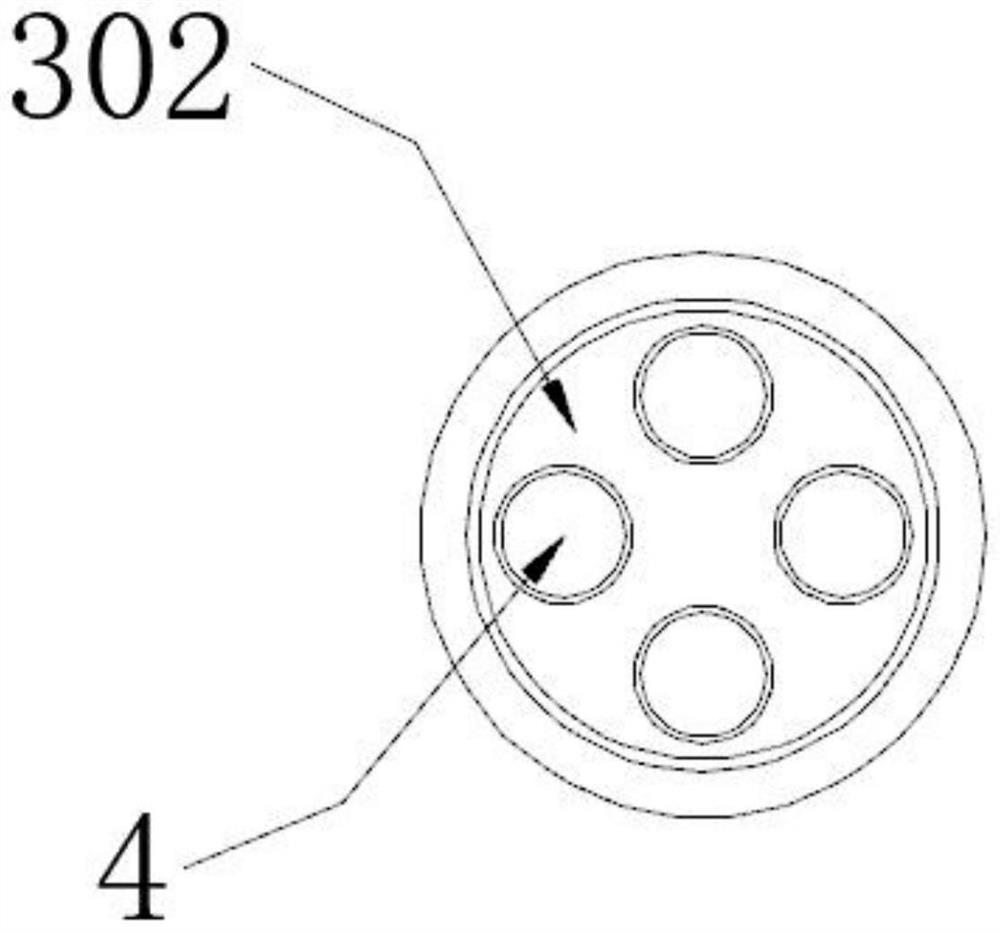

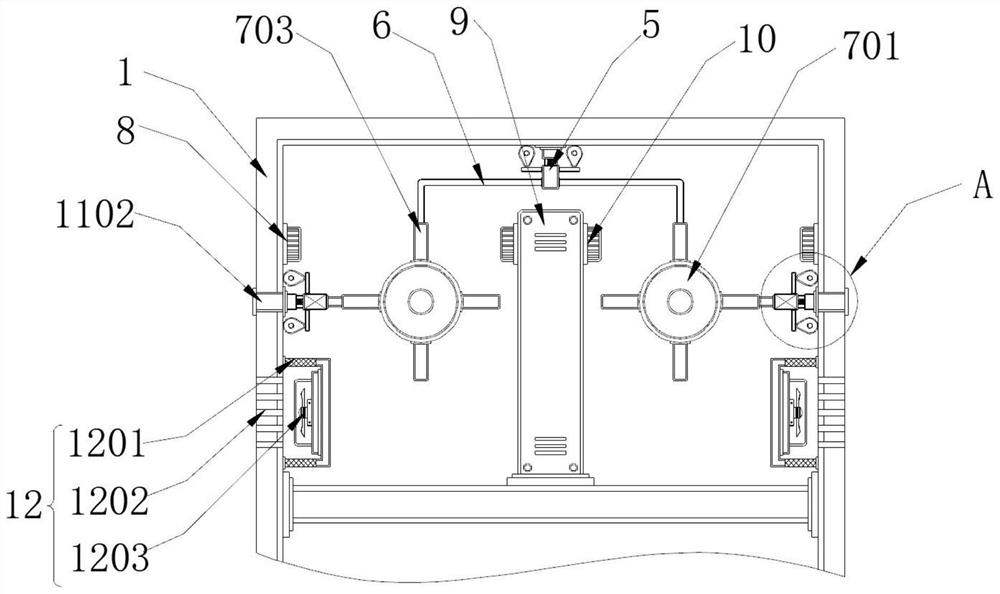

[0029] see Figure 1-7 , the present invention provides a technical solution: a multi-component waste gas online monitor, comprising an outer casing 1, a detection assembly 7 and a second gas transmission assembly 11, a display screen 2 is connected to the outer side of the front part of the outer casing 1, and the outer casing The top outer side of the body 1 is provided with a suction assembly 3, the inner side of the suction assembly 3 is connected with a gas delivery pipe 4, and the end of the gas delivery pipe 4 is provided with a first gas delivery assembly 5, and the bottom sides of the first gas delivery assembly 5 are connected on both sides. There is a communication pipe 6, and the detection assembly 7 is arranged at the end of the communication pipe 6. The detection assembly 7 includes a rotating seat 701, a motor 702, a detection room 703 and an air outlet 704. The outer end of the rotating seat 701 is connected with a motor 702, and the rotating seat The outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com