Concentration-controllable dust generating device and method

A technology for dust generation and flow control devices, which is applied in measuring devices, suspension and porous material analysis, particle suspension analysis, etc. It can solve problems such as difficult to accurately quantify dust concentration, difficult to achieve portability and mobility, and complicated equipment manufacturing. , to achieve the effect of precise control of dust concentration, simple structure and strong operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

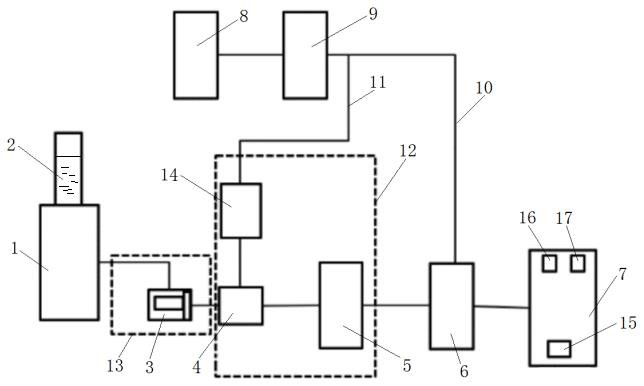

[0034] Such as figure 1 As shown, a dust generation device with controllable concentration includes a syringe pump 1, an atomization device 3, a high-temperature gasification device 4, a diffusion chamber 5, a mixing chamber 6, a sampling chamber 7, an air source pretreatment device 8, and a flow control The device 9 and the heating module 14; the injection pump 1, the atomization device 3, the high temperature gasification device 4, the diffusion chamber 5, the mixing chamber 6, and the sampling chamber 7 are sequentially connected; one end of the flow control device 9 is connected to the gas The source pretreatment device 8 is connected, and the other end is connected with the mixing chamber 6 through the mixed gas path 10; one end of the heating module 14 is connected with the high-temperature gasification device 4, and the other end is connected with the mixed gas path through the vaporized gas path 11 10 connected.

Embodiment 2

[0036] As a further preferred implementation of the above embodiment, a controllable concentration dust generating device includes a syringe pump 1, an atomization device 3, a high temperature gasification device 4, a diffusion chamber 5, a mixing chamber 6, a sampling chamber 7, a gas source The processing device 8, the flow control device 9 and the heating module 14; the injection pump 1, the atomization device 3, the high temperature gasification device 4, the diffusion chamber 5, the mixing chamber 6, and the sampling chamber 7 are sequentially connected; the flow control device 9 One end of the heating module 14 is connected to the gas source pretreatment device 8, and the other end is connected to the mixing chamber 6 through the gas mixing circuit 10; It is connected with the mixed gas path 10. The sampling chamber 7 is provided with a main sampling port 16 , a comparison sampling port 17 and a dust concentration sensor 15 .

Embodiment 3

[0038] As a further preferred implementation of the above embodiment, a controllable concentration dust generating device includes a syringe pump 1, an atomization device 3, a high temperature gasification device 4, a diffusion chamber 5, a mixing chamber 6, a sampling chamber 7, a gas source The processing device 8, the flow control device 9 and the heating module 14; the injection pump 1, the atomization device 3, the high temperature gasification device 4, the diffusion chamber 5, the mixing chamber 6, and the sampling chamber 7 are sequentially connected; the flow control device 9 One end of the heating module 14 is connected to the gas source pretreatment device 8, and the other end is connected to the mixing chamber 6 through the gas mixing circuit 10; It is connected with the mixed gas path 10. The dust-generating solution 2 is filled in the glass syringe of the syringe pump 1 . The dust-generating solution is a clear solution with known concentration and no suspended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com