Transparent jelly strip colloid and preparation method thereof

A jelly and transparent technology, applied in the field of jelly strip underwear, can solve the problems of unstable viscosity, poor elastic activity, weakened stretch, etc., and achieve the effects of convenient molding, good elasticity and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

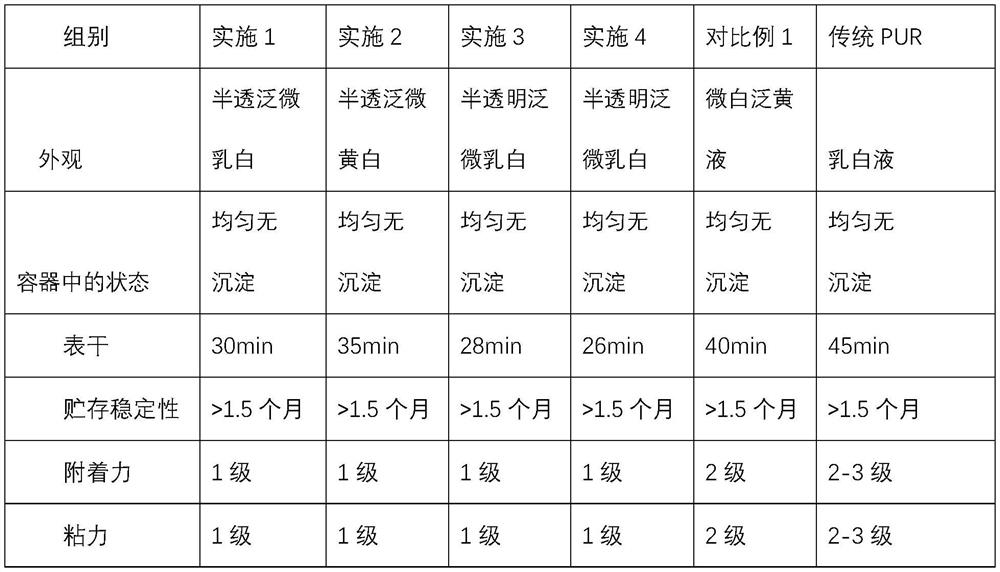

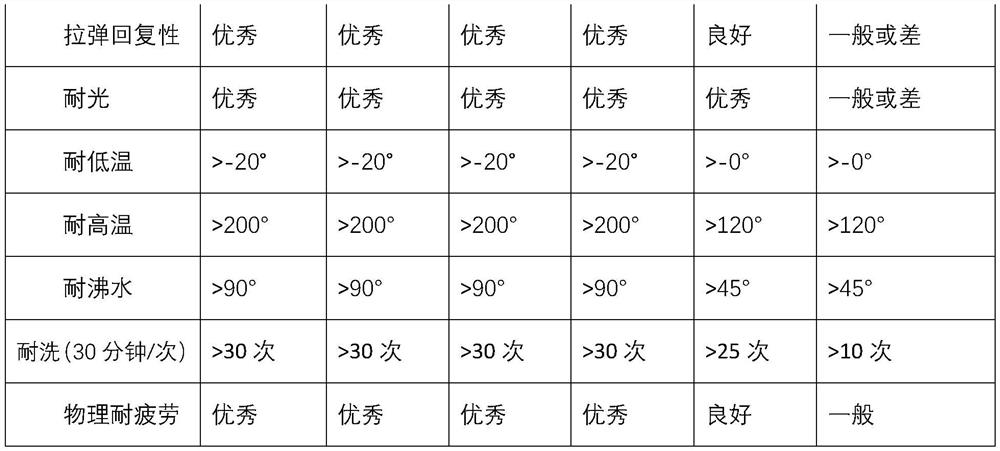

Examples

Embodiment 1

[0029] A transparent jelly bar colloid, A glue and B glue; A glue includes the following components by weight: 15 parts of polyurethane silicone, 5 parts of curing agent, 10 parts of thinner, 1 part of thickener, 5 parts of adhesive , 40 parts of deionized water; B glue includes the following components by weight: 18 parts of polyurethane silicone, 5 parts of thinner, 1 part of thickener, 5 parts of adhesive, 0.5 parts of delay agent, 40 parts of deionized water Parts; the weight ratio of glue A to glue B is 7:3.

[0030] A preparation method of transparent jelly bar colloid, comprising the following steps:

[0031] Step 1, preparation of glue A;

[0032] S1. Weigh polyurethane silicone, curing agent, diluent, thickener, adhesive and deionized water respectively;

[0033] S2. Add polyurethane silicone and deionized water into the container, heat up to 80°C, and keep it warm for 1 hour;

[0034] S3. Add the adhesive and stir for 15 minutes, continue to react for 2 hours, con...

Embodiment 2

[0048] A transparent jelly bar colloid, glue A and glue B: glue A includes the following components by weight: 20 parts of polyurethane silicone, 8 parts of curing agent, 18 parts of thinner, 3 parts of thickener, and 10 parts of adhesive , 80 parts of deionized water; B glue includes the following components by weight: 22 parts of polyurethane silicone, 8 parts of thinner, 3 parts of thickener, 10 parts of adhesive, 1 part of delay agent, 80 parts of deionized water Parts; the weight ratio of glue A to glue B is 7:3.

[0049] A preparation method of transparent jelly bar colloid, comprising the following steps:

[0050] Step 1, preparation of glue A;

[0051] S1. Weigh polyurethane silicone, curing agent, diluent, thickener, adhesive and deionized water respectively;

[0052] S2. Add polyurethane silicone and deionized water into the container, raise the temperature to 90°C, and keep it warm for 2 hours;

[0053] S3. Add the adhesive and stir for 30 minutes, continue to re...

Embodiment 3

[0067] A transparent jelly strip colloid, glue A and glue B: glue A includes the following components by weight: 15 parts of polyurethane silicone, 5 parts of curing agent, 10 parts of diluent, 1 part of thickener, and 5 parts of adhesive , 40 parts of deionized water; B glue includes the following components by weight: 22 parts of polyurethane silicone, 8 parts of thinner, 3 parts of thickener, 10 parts of adhesive, 1 part of delay agent, 80 parts of deionized water Parts; the weight ratio of glue A to glue B is 7:3.

[0068] A preparation method of transparent jelly bar colloid, comprising the following steps:

[0069] Step 1, preparation of glue A;

[0070] S1. Weigh polyurethane silicone, curing agent, diluent, thickener, adhesive and deionized water respectively;

[0071] S2. Add polyurethane silicone and deionized water into the container, raise the temperature to 90°C, and keep it warm for 2 hours;

[0072] S3. Add the adhesive and stir for 30 minutes, continue to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com