Chain ring curing tool and method for connecting chain rings into chain rigging

A technology of chain rings and tooling, which is applied in the field of traction rigging, can solve the problems of not providing intermediate composite fiber material chain rings, etc., and achieve the effects of improving service life, reducing chain weight, and reducing chemical destructive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] A kind of chain ring solidification tooling, comprises upper inner mold 61, lower inner mold 62, upper outer mold 63 and lower outer mold 64, described upper inner mold 61 and lower inner mold 62 are assembled into annular mold cavity III, and described annular mold There is a gap III 65 on the cavity III, and the upper outer mold 63 and the lower outer mold 64 are both provided with annular groove structures, and the annular groove structures of the upper outer mold 63 and the lower outer mold 64 are assembled into an annular mold cavity IV, The annular mold cavity III is located in the annular mold cavity IV, and the external dimensions of the annular mold cavity III are consistent with the internal dimensions of the annular mold cavity IV. The upper outer mold 63 is provided with a gap IV 66, and the lower outer mold 64 is provided with a notch V67, the notch IV66 communicates with the annular groove structure of the upper outer mold 63 where it is located, the notch ...

specific Embodiment approach 2

[0027] A method for quickly connecting continuous fiber-reinforced composite material chain rings into chain slings. The prefabricated chain rings are designated as N rings, the cross-sectional diameter is D, and the chain rings before and after connecting the chain ring N rings are respectively N-1 rings and N+ Ring 1 and Ring N are set horizontally, and Ring N-1 and Ring N+1 are set vertically to Ring N, which specifically includes the following steps:

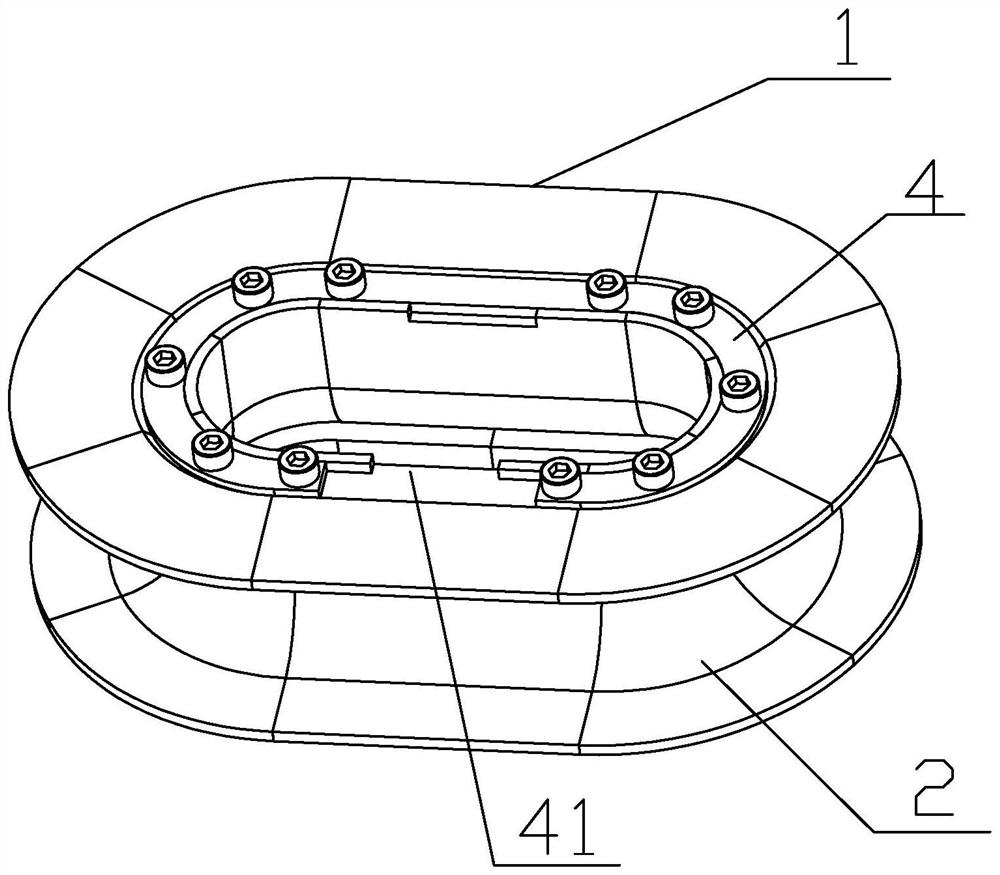

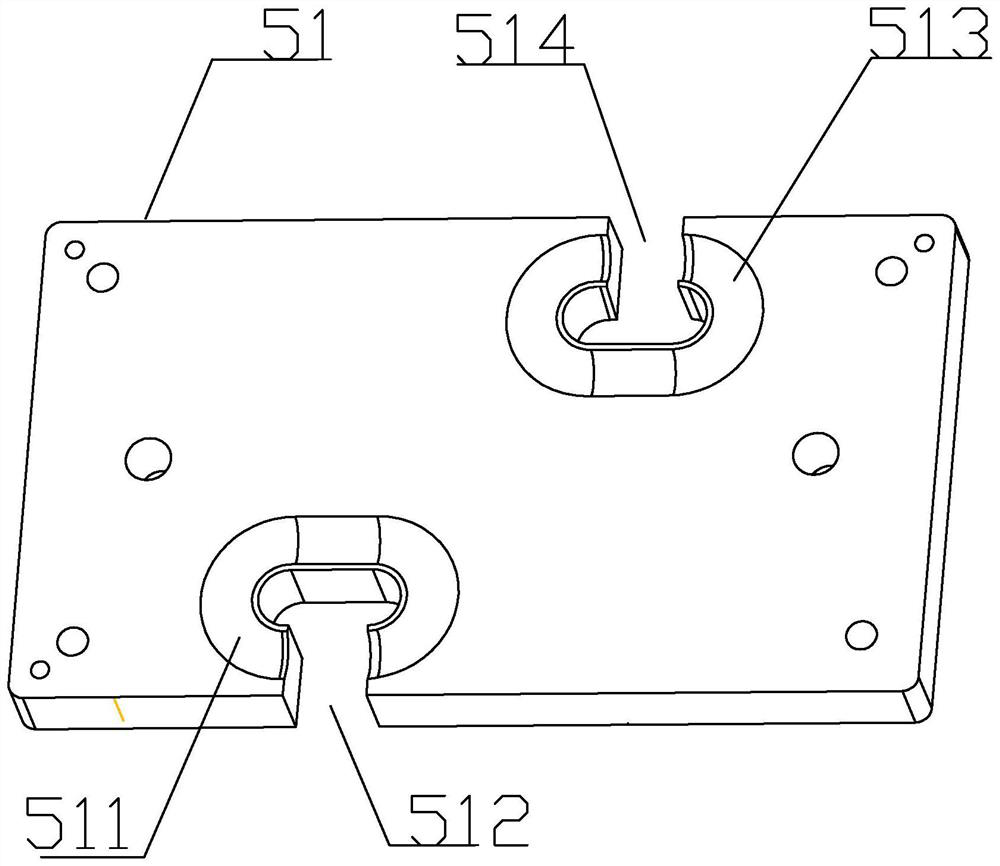

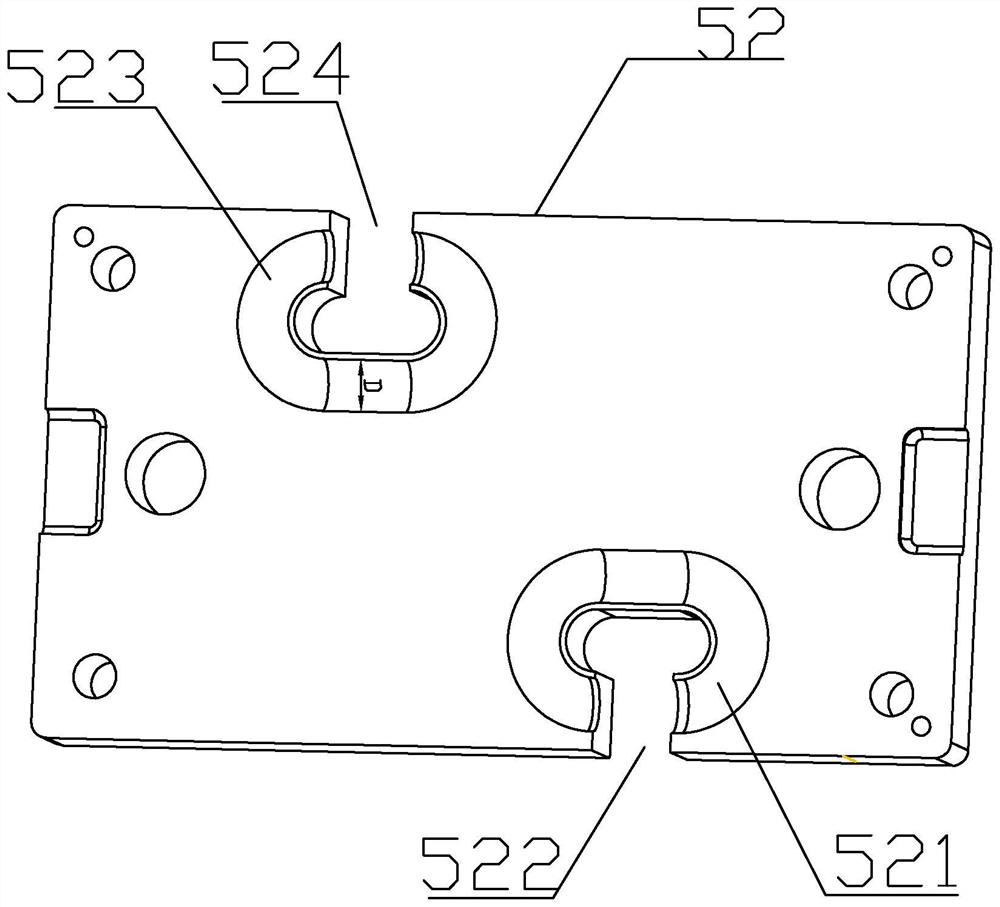

[0028] Step 1. Circumferential forming: fix the N-1 ring and N+1 ring at a distance of 1.5D with a clamp, and put them on the chain ring forming tooling. The forming tooling includes several modules 1, and the several Each module 1 is assembled into a closed annular structure, and the circumferential direction of the annular structure is provided with an annular groove I2. The central axes are coincident, and the forming tooling also includes an annular clamp 4, the annular clamp 4 is provided with a gap VI41, and several mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com