Method for the production of a bladder accumulator and bladder accumulator produced according to said method

A technology of airbag accumulators and accumulators, applied in the direction of accumulator devices, actuator accumulators, outer walls of container structures, etc., can solve problems such as unavoidable different structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

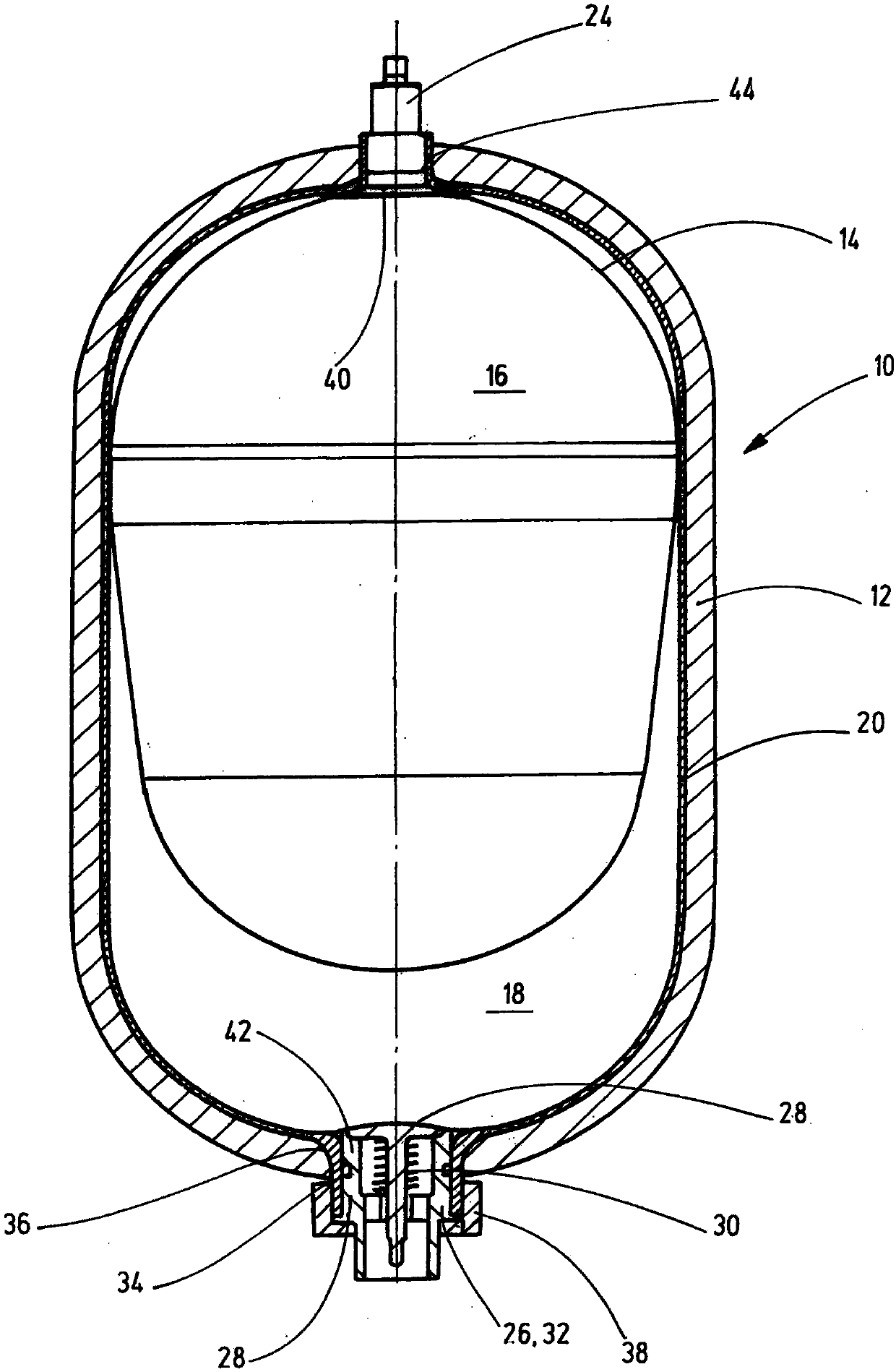

[0022] The bladder-type accumulator shown in the figure and generally designated 10 has an accumulator housing 12 which connects two medium chambers 16 , 18 by means of a bladder body 14 or accumulator bladder. separated from each other. The first medium chamber 16 of the bladder accumulator 10 is usually used to contain a working gas, such as nitrogen, and the second medium chamber 18 contains a liquid, such as hydraulic oil or the like. This means that the aforementioned medium chambers 16 , 18 correspond to the usual gas or liquid side of the bladder-type accumulator 10 .

[0023] The accumulator housing 12 is constructed in the form of a composite pressure vessel with an inner plastic core vessel 20 which is wound on the outer peripheral side with plastic fibers forming a plastic shell 22 . Instead of the plastic materials described for the plastic core container 20 and for the plastic outer shell 22 , metal materials such as aluminum, which can be easily formed and can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com