A fiber grating strain sensor and its installation method

A technology of strain sensor and fiber grating, which is applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of low sensitivity and poor sensitivity consistency of fiber grating strain sensors, and achieve material consistency and low processing accuracy requirements, and practicality Strong, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

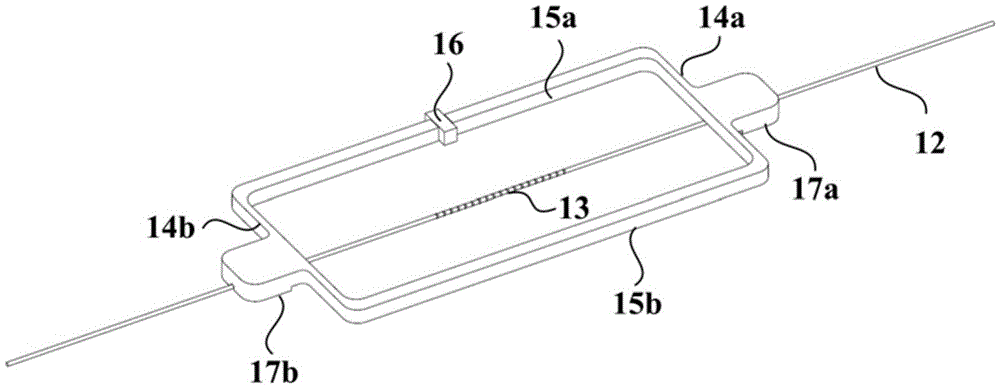

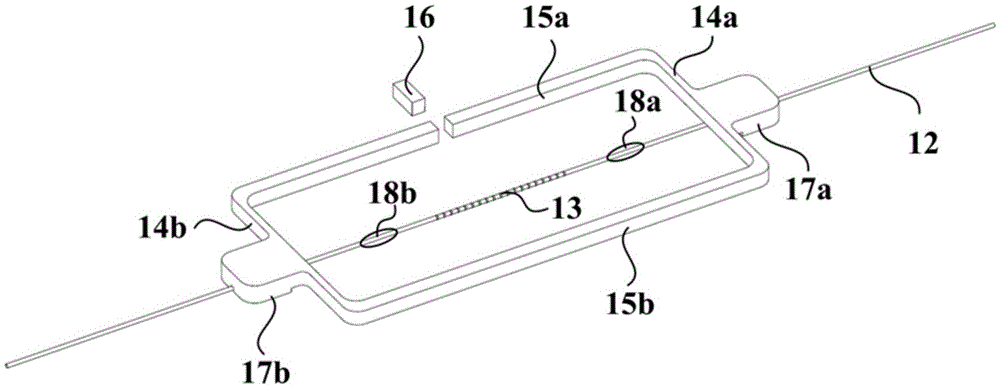

[0030] Such as figure 2 Shown is a schematic structural view of the fiber grating strain sensor of the present invention during the packaging process and before installation and use. The fiber grating strain sensor of the present invention includes a first high elastic beam 14a, a second high elastic beam 14b, a first support column 15a, a second support Column 15b, first installation base 17a, second installation base 17b, baffle 16 and fiber grating 13, wherein first high elastic beam 14a, first support column 15a, second high elastic beam 14b and second support column 15b in sequence The connection forms a box structure, and the four corners of the formed box structure can be rounded or right-angled.

[0031] The first installation base 17a is connected to the first high elastic beam 14a, the second installation base 17b is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com