Novel automatic universal clamping system

A new type of clamping technology, applied in the field of mechanical processing, can solve the problems that affect the overall quality of the product and cannot guarantee the consistency of the multi-level surface of the hole system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

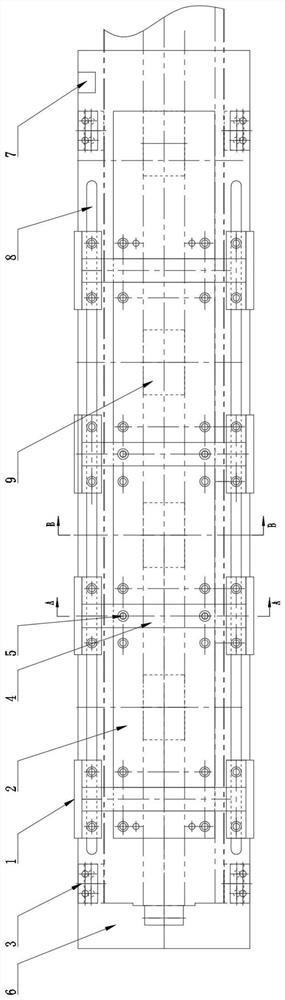

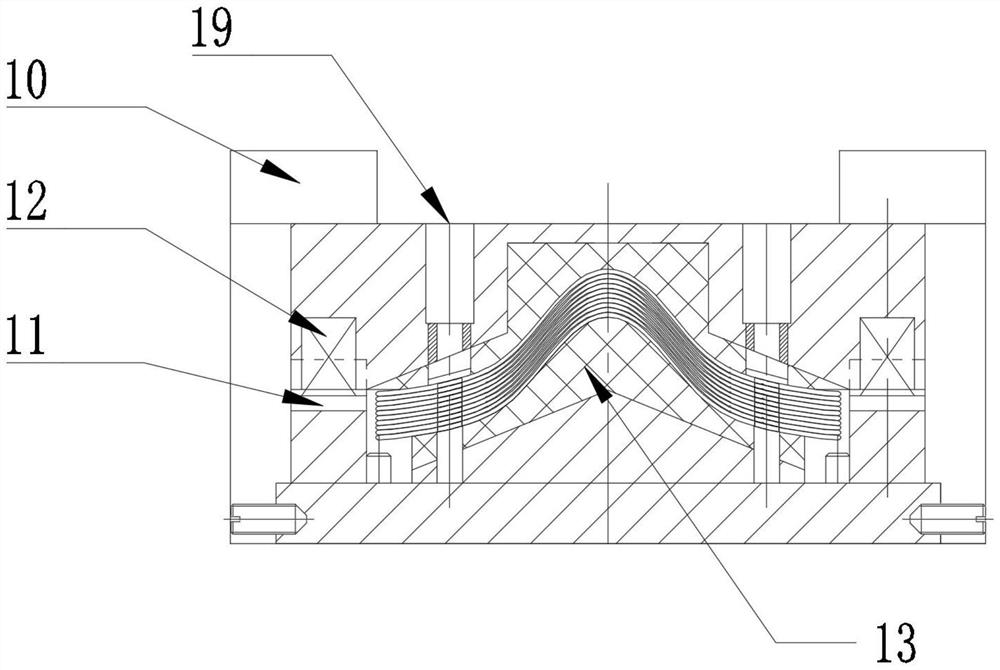

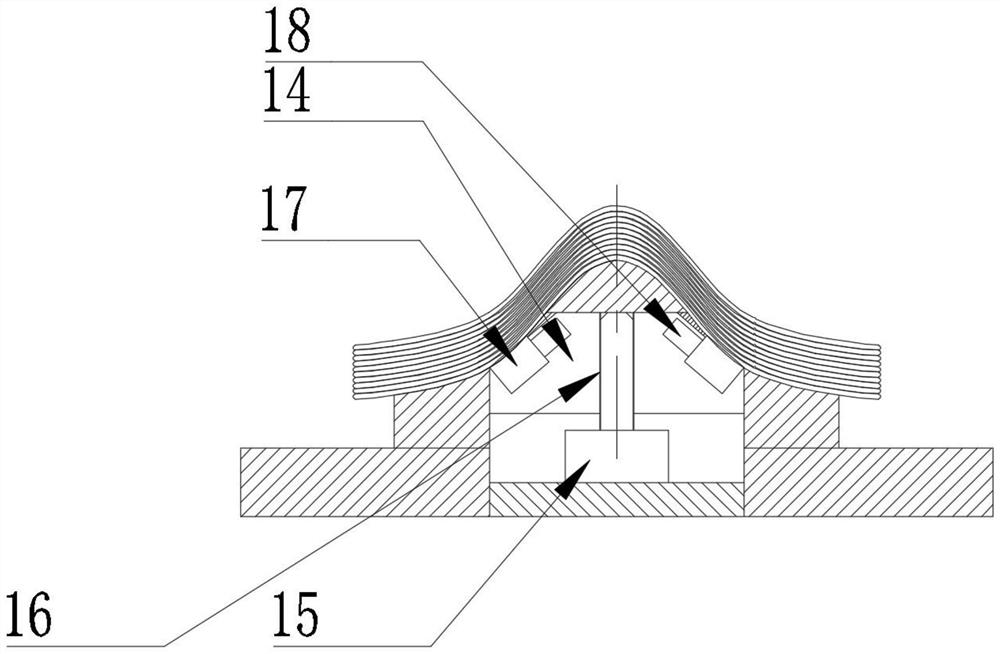

[0020] like figure 1 As shown, the present embodiment provides a new type of automatic general-purpose clamping system, including a fixed base 1, the number of which is several, and clamps the workpiece 2, and the workpiece 2 is also provided with a movable positioning support 3. The positioning supports 3 are arranged at both ends of the workpiece 2, and the number is four. The fixed bases 1 are respectively arranged on both sides of the workpiece 2. The fixed bases 1 on both sides form a group, and positioning and fixing brackets are installed between each group of fixed bases 1. Plate 4, the positioning and fixing plate 4 is provided with a drill sleeve 5, one end of the workpiece 2 is provided with a limit support 6, a pressure sensor is provided on the limit support 6, a photoelectric sensor 7 is also installed on the workpiece 2, and a fixed base on each side 1 is installed with a mounting substrate 8, and a transmission module 9 is provided at the interval between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com