Welding device for electric vehicle hub

A welding device and electric vehicle technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity and low production efficiency of manual clamping, so as to avoid the process of manual clamping and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

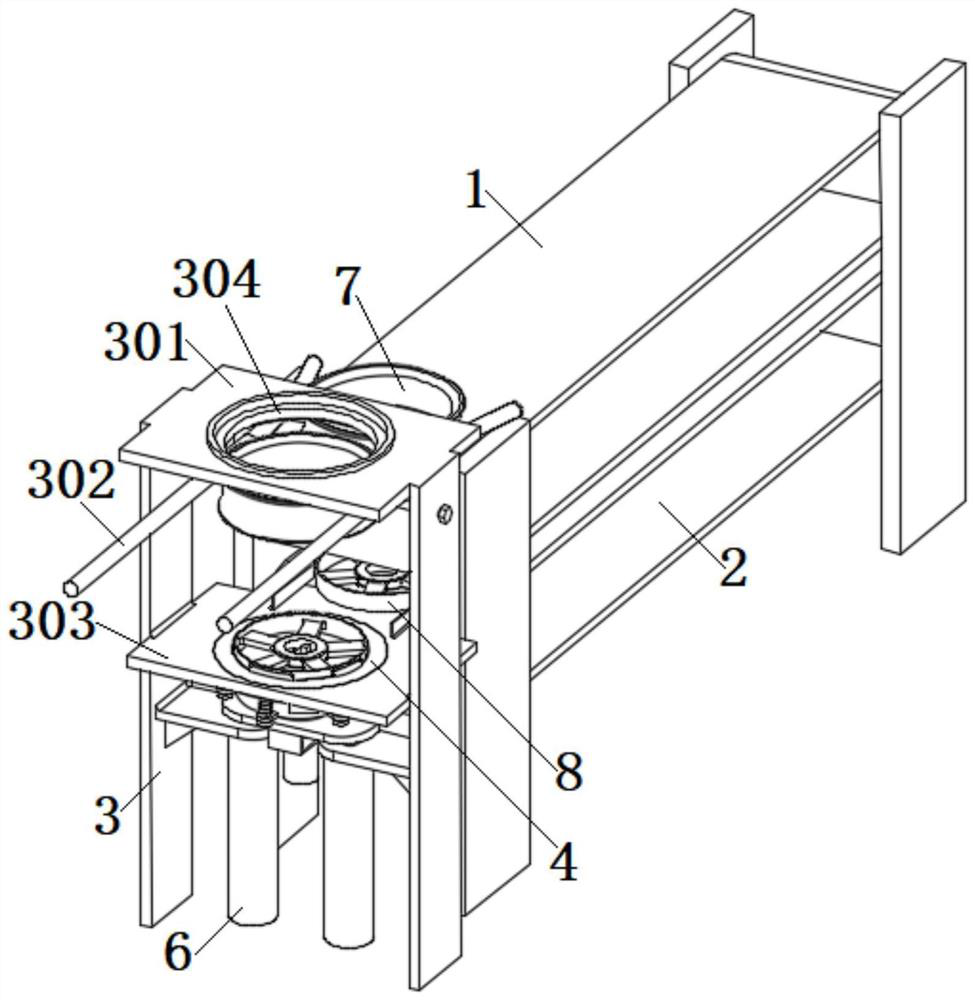

[0029] like figure 1 and 2 As shown, the present invention provides a welding device for an electric wheel hub, including a rim conveying mechanism 1 and a spoke conveying mechanism 2, a clamping mechanism, an upper top ring 4 and a telescopic mechanism 6, and the rim conveying mechanism 1 is located at Directly above the spoke conveying mechanism 2, both the rim conveying mechanism 1 and the spoke conveying mechanism 2 can be stepping conveyors.

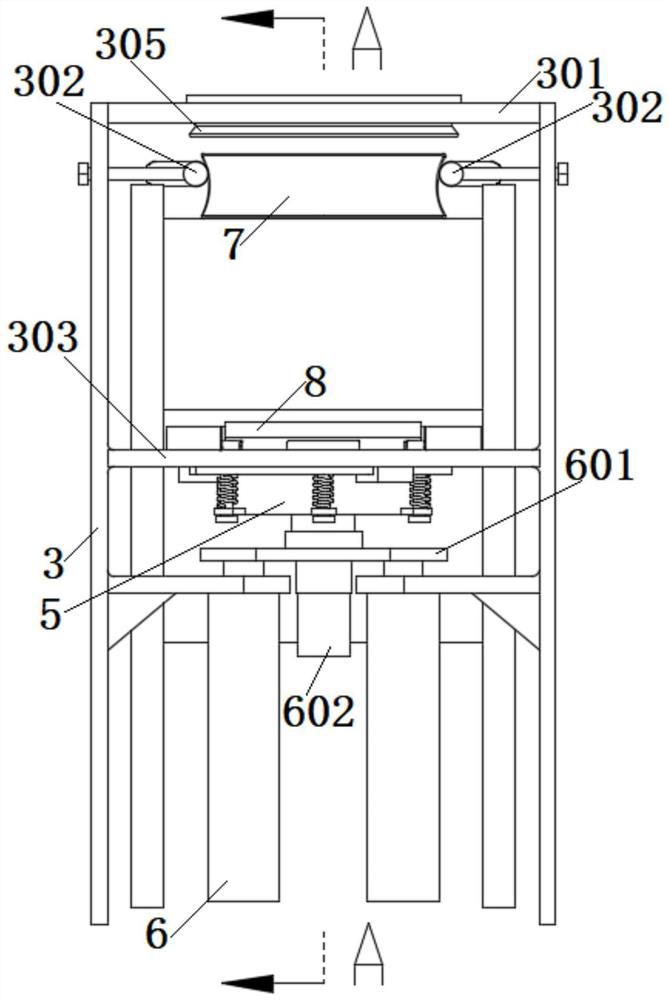

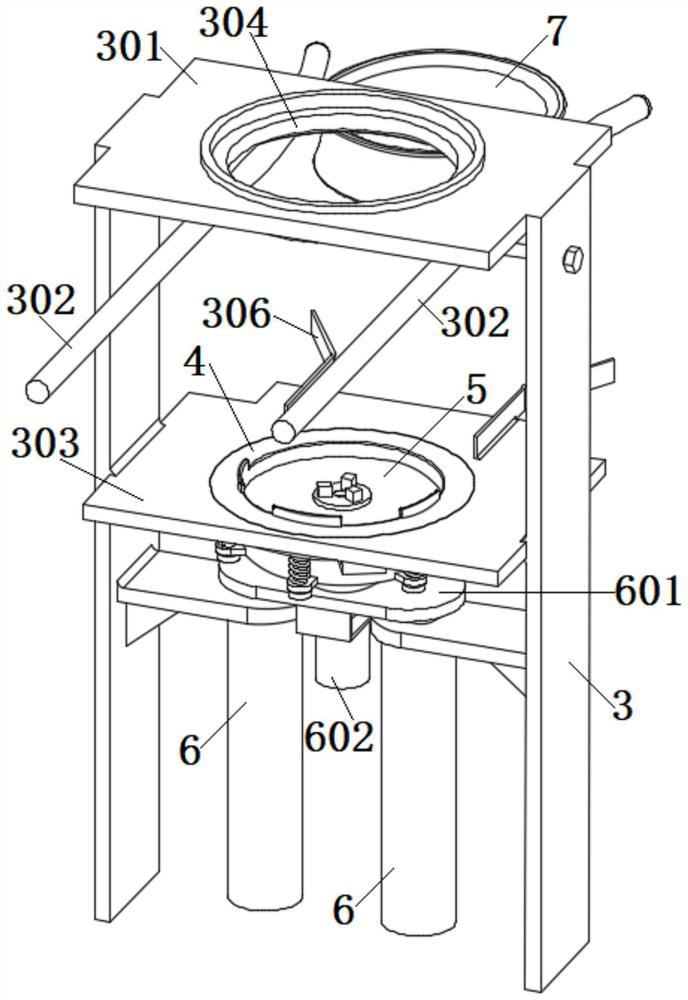

[0030] like Figure 3-5 As shown, the clamping mechanism includes a frame 3, and the frame 3 is sequentially connected with a top plate 301, a pair of guide rods 302, and a bottom plate 303 from top to bottom; the top plate 301 is provided with a round hole, and a positioning ring is rotated in the round hole 304, the lower surface of the positioning ring 304 is welded with a trumpet-shaped circular ring plate 305.

[0031] The guide rod 302 corresponds to the position of the rim conveying mechanism 1, and the two guide rods 302 ...

Embodiment 2

[0045] On the basis of Example 1, as Image 6 As shown, three to six connecting lugs 502 are welded on the circumferential surface of the chuck 5, and the connecting lugs 502 are movably interspersed with pin shafts 503; The spring 504 is located between the lug 502 and the top ring 4 .

[0046] Moreover, the upper surface of the chuck 5 is lower than the upper surface of the upper top ring 4. Since the upper top ring 4 is lower than the surface of the chuck 5, after the spoke 8 enters the position of the through hole, it is used for positioning the spoke 8 through the inner wall of the upper top ring 4. , so that the spoke 8 can be better ensured to be concentric with the chuck 5, improving the reliability and accuracy of clamping.

[0047] After the upper top ring 4 contacts with the rim 7, and the rim 7 is pushed to contact with the lower surface of the positioning ring 304, the upper top ring 4 cannot continue to rise, and the position is limited. Continue to rise under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com