Combined mineral separation and purification method for kaolin ore or kaolin tailings

A technology for kaolinite tailings and kaolinite ore, which is applied in the field of joint beneficiation and purification of kaolinite or kaolinite tailings, and can solve the problems of backward beneficiation and separation and purification technology, low quality and grade of output products, and no high-purity product output. , to achieve the effect of obvious comprehensive industrial efficiency benefits and value, high product quality, and large scale of comprehensive output value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

[0066] The invention is mainly applied to the beneficiation and purification process of high-purity kaolin, high-purity quartz, high-purity muscovite, iron lepidolite, and high-purity feldspar for ore dressing and purification of kaolin ore (or kaolin tailings). Mineral processing and purification of kaolin ore (or kaolin tailings) and other non-metallic ores, including: quartz ore, white (lithium) mica ore, lithium feldspar ore, feldspar ore, tantalum and niobium ore, etc. combined flotation separation and purification.

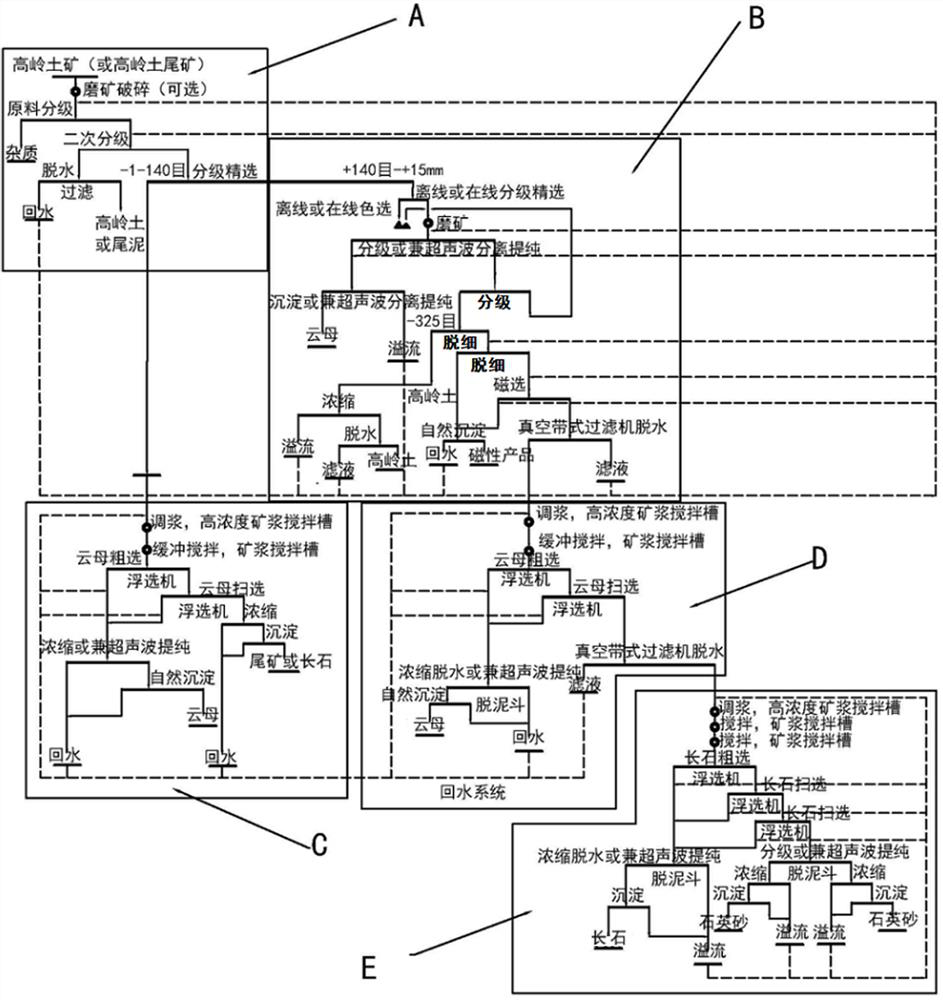

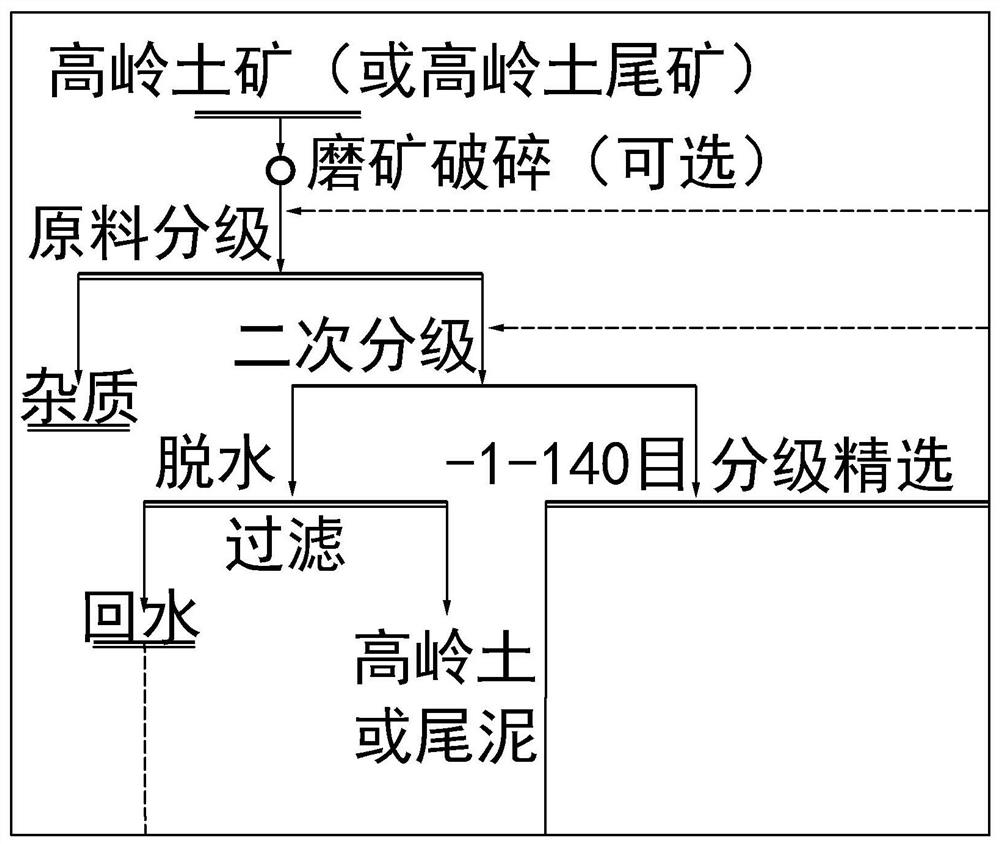

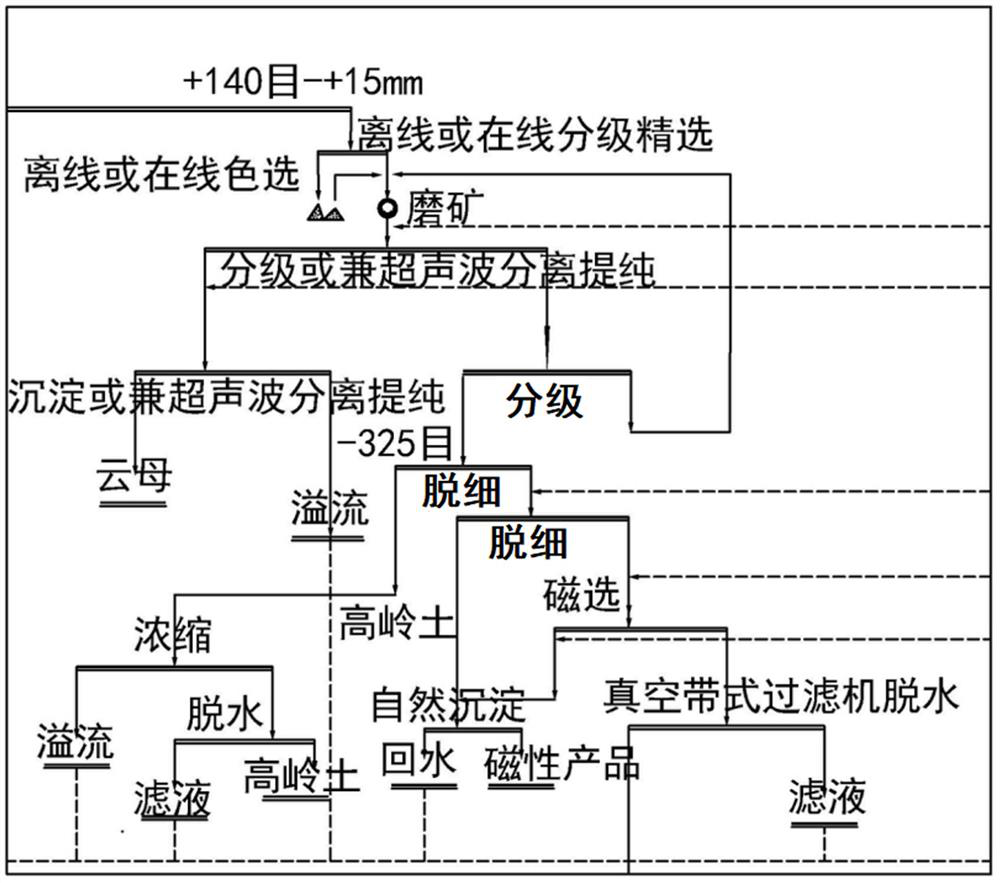

[0067] The present invention relates to a combined beneficiation and purification method of kaolin ore or kaolin tailings, which includes: one or more of kaolin separation process, mica separation process, feldspar separation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com