Sample plate combination for online overlaying of star wheel tooth plate, and online overlaying method

A technology of star gear teeth and templates, which is applied in the field of sintering machine equipment maintenance, can solve the problems of long maintenance time and difficulty in quality assurance of gear plate installation, and achieve the effects of saving maintenance time, avoiding overall shedding, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

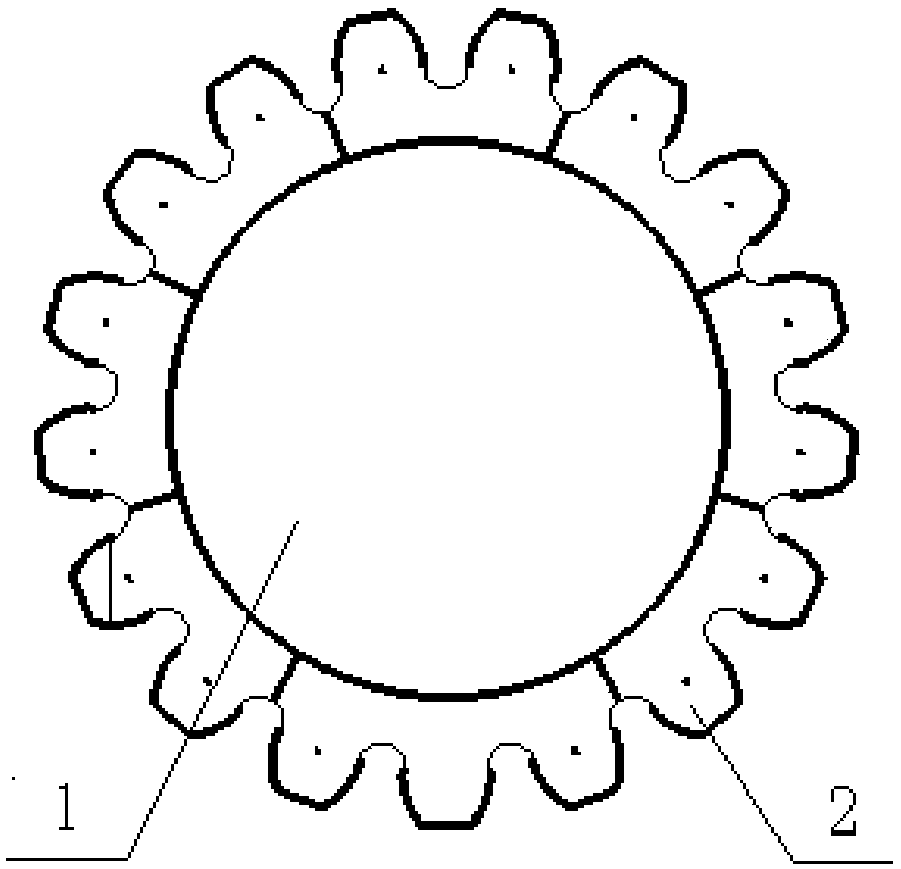

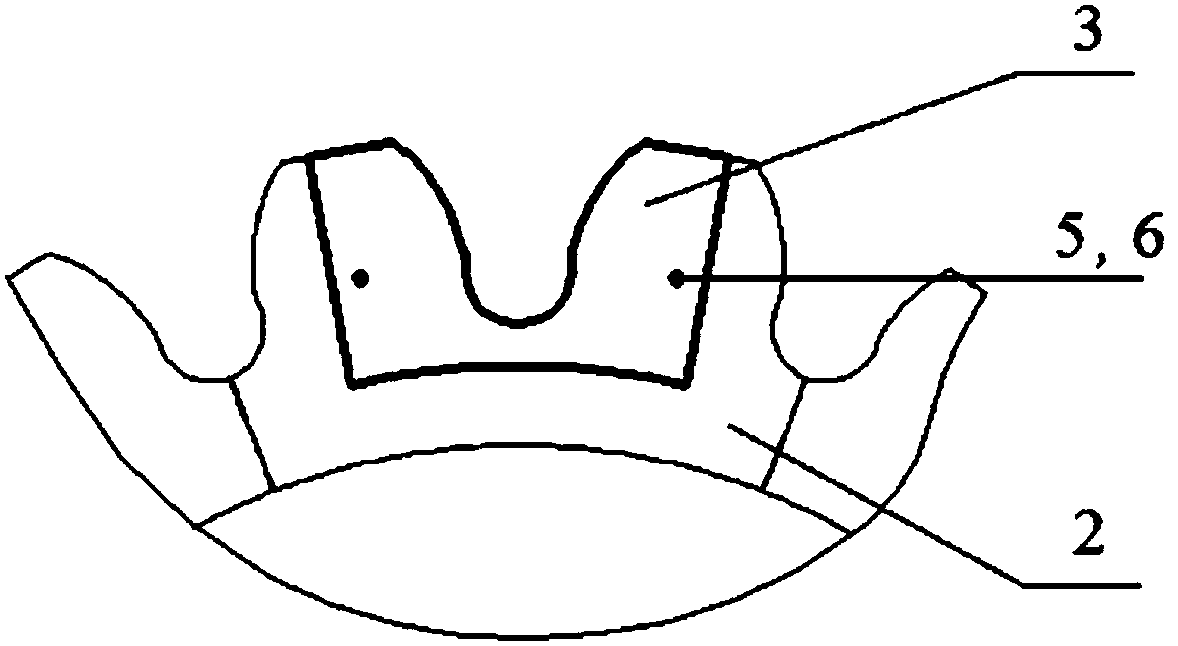

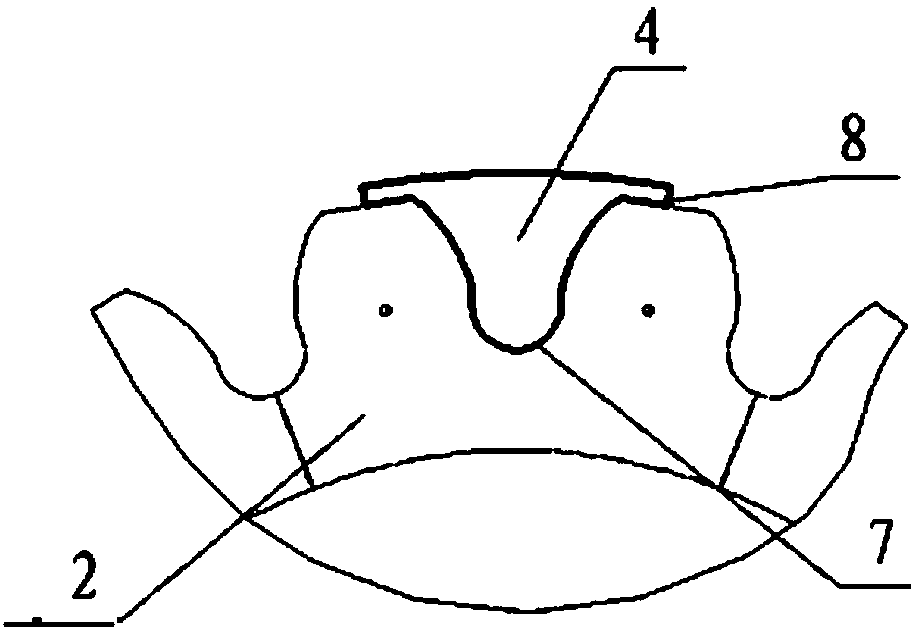

[0047] combine figure 1 , figure 2 , image 3 , Figure 4 As shown, the embodiment of the present invention provides a template combination for on-line surfacing welding of a star gear tooth plate, including: an outer template 3, an inner template 4 and a positioning pin 5; the outer template 3 has two pieces, fixedly arranged on the star gear teeth On both sides of the plate 2, an arc-shaped curved surface is processed on the outer template 3, and the shape and size of the arc-shaped curved surface are the same as those of the star gear tooth plate 2. The outer sample plate 3 is used to compare the shape of the star gear tooth plate 2 during surfacing welding, that is, the outline formed by the two outer sample plates 3 is the outline of the tooth plate that is expected to be surfacing. The groove-shaped area formed between the surface of the plate is the area that needs to be filled by surfacing welding. When surfacing welding, the outer sample plate 3 can be observed in...

Embodiment 2

[0050] An online surfacing welding method for a star gear tooth plate provided by an embodiment of the present invention includes:

[0051] Step S1: Perform pre-welding treatment on the star gear plate of the sintering machine that needs to be repaired;

[0052] Step S2: According to the size of the star wheel tooth plate, one inner template and two outer templates are produced in Example 1;

[0053]Step S3: Fix the two outer templates on both sides of the star wheel tooth plate. In this embodiment, drill a mounting hole with a diameter of 21.8mm according to the position on the drawing, coincide with the original positioning hole on the star wheel tooth plate, and insert them together The positioning pin with a diameter of 21.6mm is positioned, and the rest of the outer sample plate is firmly fixed with the star wheel tooth plate. After the outer sample plate is installed, the working surface of the outer sample plate and the star wheel tooth plate forms a groove body to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com