Production process of high-strength core

A production process and high-strength technology, applied in medical science, absorbent pads, bandages, etc., can solve problems such as side leakage and core faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

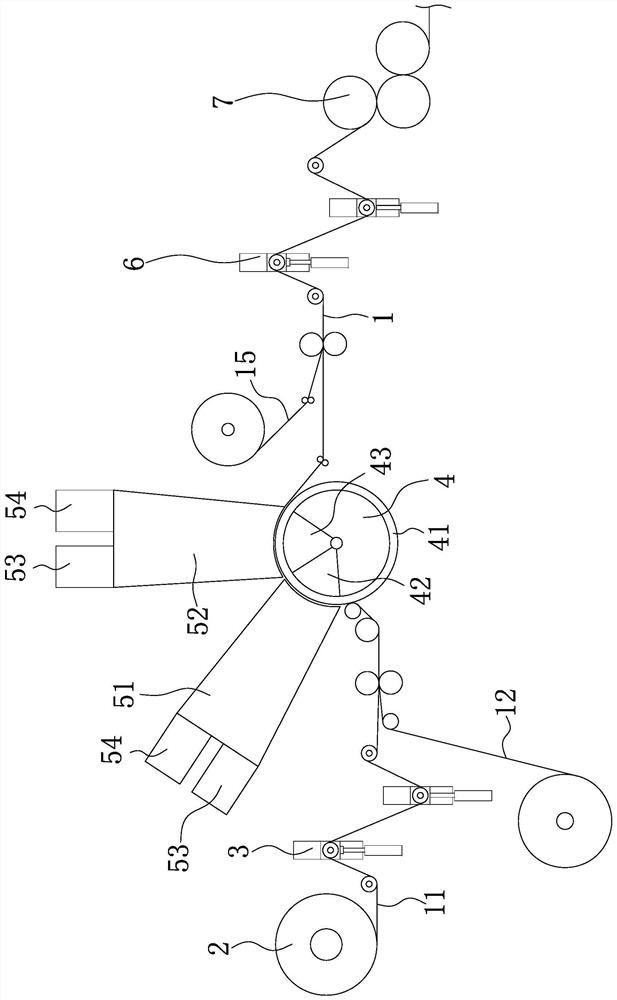

[0031] refer to Figure 1 to Figure 6 , the present embodiment provides a production process for a high-strength core, comprising the following steps:

[0032] (1) The foam net 11 is transported by driving the conveying roller 2 through the driving motor. After the foam net 11 enters the first buffer mechanism 3, it is compounded with the bottom non-woven fabric 12, and then enters the mold wheel 4;

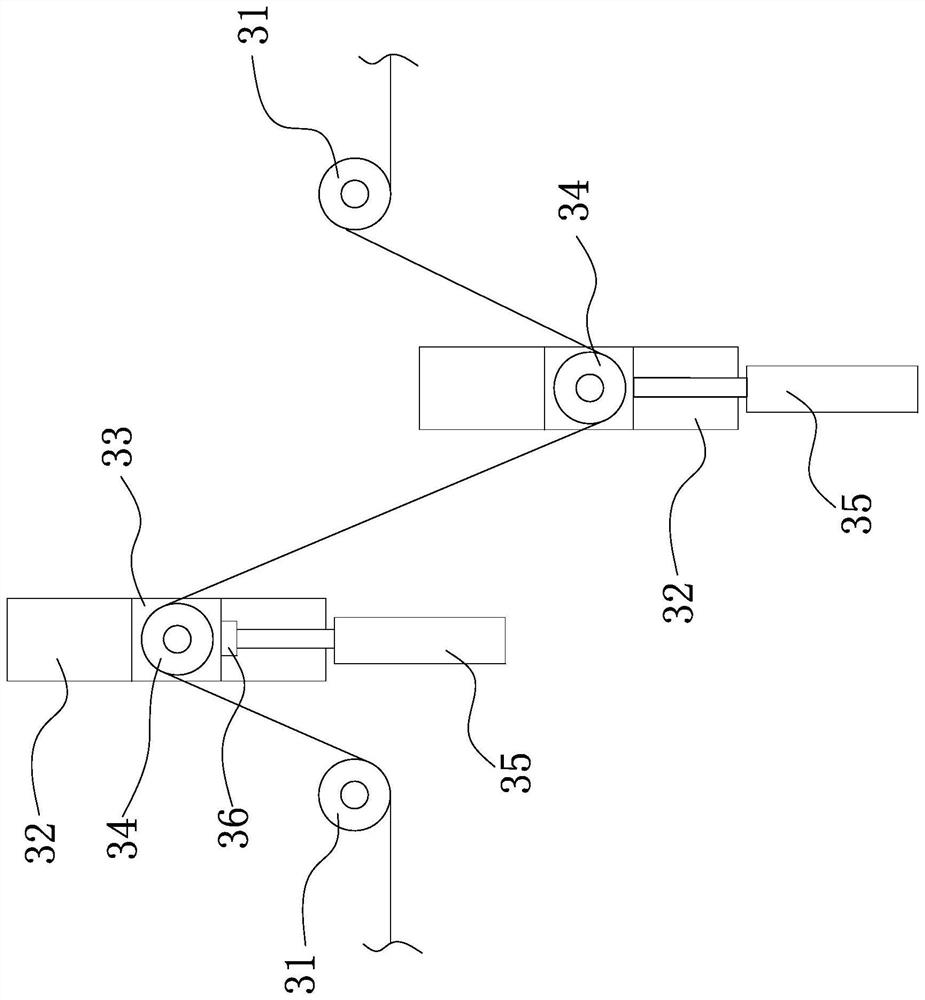

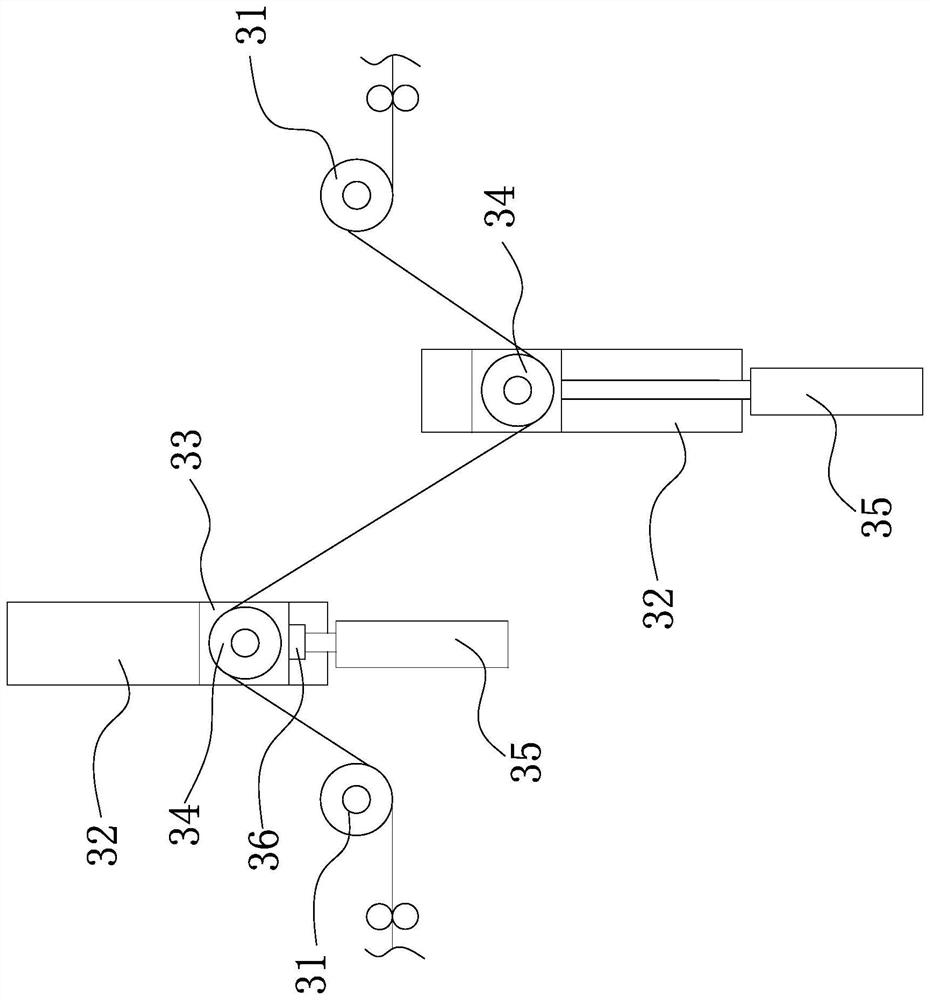

[0033] The first buffer mechanism 3 includes two fixed rollers 31 arranged horizontally, two lifting grooves 32 between the two fixing rollers 31, a lifting seat 33 that can be lifted and slidably arranged on the lifting groove 32, and is rotatably arranged on the lifting groove 32. The lifting roller 34 of the lifting seat 33, the telescopic cylinder 35 that drives the lifting seat 33 to lift, one of the telescopic cylinders 35 is connected with the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com