Control method and device of cooking equipment, cooking equipment and readable storage medium

A technology of cooking equipment and a control method, which is applied in the field of control and can solve problems affecting user experience and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

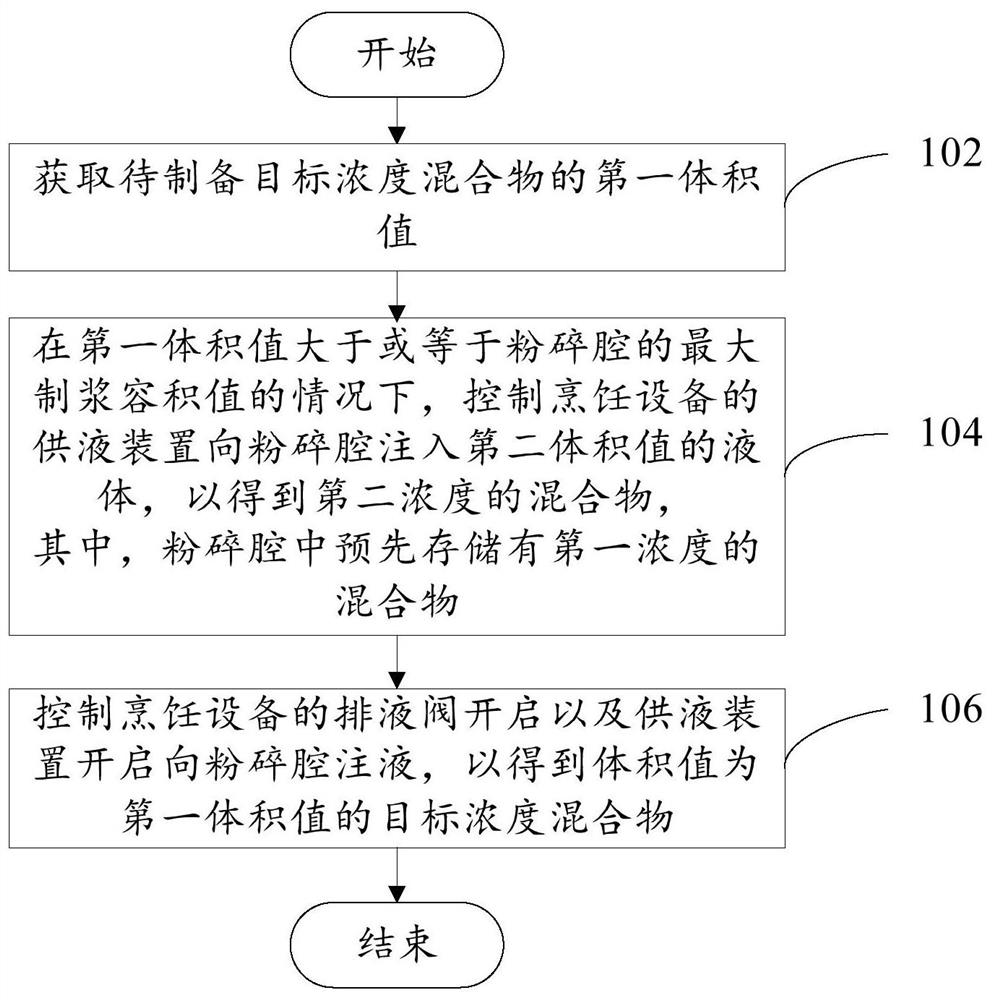

[0074] Such as figure 1 As shown, according to the first aspect of the present invention, the present invention provides a control method of cooking equipment, the cooking equipment includes a body, the body has a crushing chamber capable of storing a mixture of a first concentration, and the control method of cooking equipment includes:

[0075] Step 102, obtaining the first volume value of the target concentration mixture to be prepared;

[0076]Step 104, when the first volume value is greater than or equal to the maximum pulping volume of the crushing chamber, control the liquid supply device of the cooking equipment to inject a second volume of liquid into the crushing chamber to obtain a mixture of a second concentration, wherein , the crushing cavity is pre-stored with a mixture of the first concentration;

[0077] Step 106, controlling the opening of the liquid discharge valve of the cooking device and the opening of the liquid supply device to inject liquid into the p...

Embodiment 2

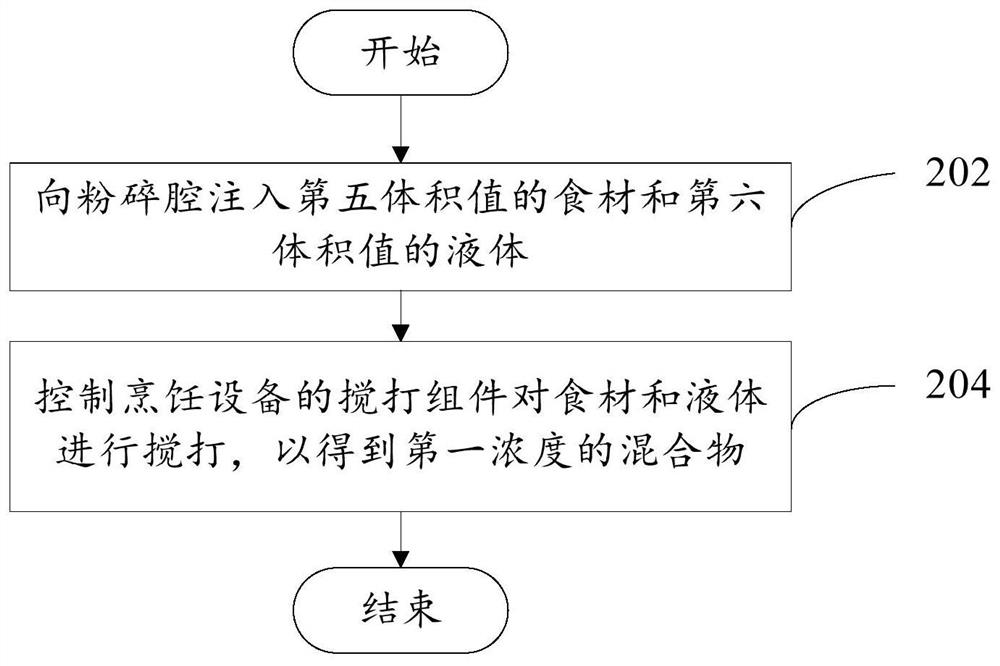

[0085] In this embodiment, the control process of discharging slurry while injecting liquid is specifically defined, specifically, the volume of the mixture of the first concentration is the fourth volume value, and the liquid supply device of the cooking equipment is controlled to inject the second volume value into the grinding chamber to obtain a mixture of the second concentration, wherein the step of storing the mixture of the first concentration in advance in the crushing chamber includes: controlling the liquid discharge valve to open, and controlling the liquid supply device to inject a seventh volume of liquid into the crushing chamber ; Wherein, the sum of the fourth volume value, the seventh volume value and the second volume value is equal to the first volume value.

[0086] In this embodiment, the method of discharging slurry while injecting liquid proposed in this application can realize the production of a mixture with a large amount of slurry, and its specific c...

Embodiment 3

[0090] In this embodiment, it is specifically defined that when the first volume value is smaller than the maximum pulping volume value of the crushing chamber, the control logic of the cooking device, specifically, controls the liquid supply device to inject a third volume of liquid into the crushing chamber , so as to obtain the target concentration mixture of the first volume value, wherein the mixture of the first concentration is pre-stored in the crushing chamber.

[0091] In this embodiment, the pulping process is specifically defined when the maximum pulping volume of the crushing chamber can meet the pulping amount of the mixture prepared at one time. At this time, the crushing of the mixture with the first concentration stored in the liquid supply device The third volume of liquid is injected into the chamber to obtain a mixture with a target concentration that meets user requirements.

[0092] In the above process, the cooking equipment can select a suitable pulping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com