Method for improving rice quality by using compound microbial agent

A compound microbial bacterial agent and bacterial agent technology, which is applied in the field of crop management, can solve the problems that the compound microbial bacterial agent cannot be well utilized and the cost is high, and achieve the effects of low cost, increased plant height, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In the retting stage, Bacillus amyloliquefaciens, yeast and nitrogen-fixing bacteria were respectively inoculated in a liquid medium for expanded culture. The liquid medium used glucose as a carbon source, peptone as a nitrogen source, and calcium chloride as an inorganic salt to regulate the culture. The base pH value is 7.2, cultivated at 30°C and 150r / min for 48h, and the viable concentration of Bacillus amyloliquefaciens is 1×10 8 individual / ml, the viable yeast concentration is 1×10 9 / ml, the live bacterial concentration of nitrogen-fixing bacteria is 2×10 8 Individual / ml, according to the ratio of Bacillus amyloliquefaciens, saccharomyces, and nitrogen-fixing bacteria=1:3:4, mix the fermentation liquid of each strain to obtain the microbial inoculum in the retting stage, dilute it with water at a ratio of 1:10, and then spray it To the middle of the field, the spraying rate is 190kg / mu;

[0056] In the tillering stage, Streptomyces, glutamic acid fermenting bac...

Embodiment 2

[0060] In the retting stage, Bacillus amyloliquefaciens, yeast and nitrogen-fixing bacteria were respectively inoculated in a liquid medium for expanded culture. The liquid medium used glucose as a carbon source, peptone as a nitrogen source, and calcium chloride as an inorganic salt to regulate the culture. The base pH value is 7.3, cultivated under the condition of 27°C and 150r / min for 48h, and the viable concentration of Bacillus amyloliquefaciens obtained is 4×10 8 Individuals / ml, the live bacterial concentration of yeast is 2×10 9 / ml, the live bacterial concentration of nitrogen-fixing bacteria is 1×10 8 Individual / ml, according to the volume ratio of Bacillus amyloliquefaciens, saccharomycetes, nitrogen-fixing bacteria = 1: 2.5: 3.5, the fermentation broth of each bacterial strain is mixed to obtain the microbial inoculum of retting stage, after diluting with water in a ratio of 1: 10 Spraying to the middle of the field, the spraying rate is 140kg / mu;

[0061] In the...

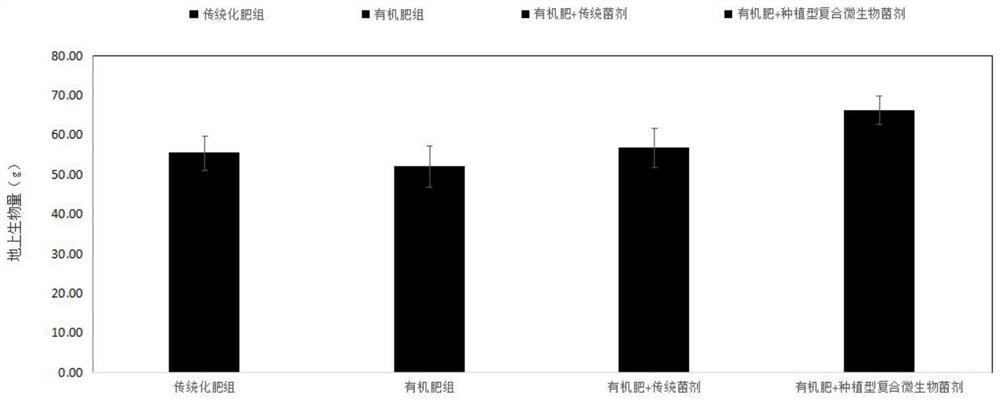

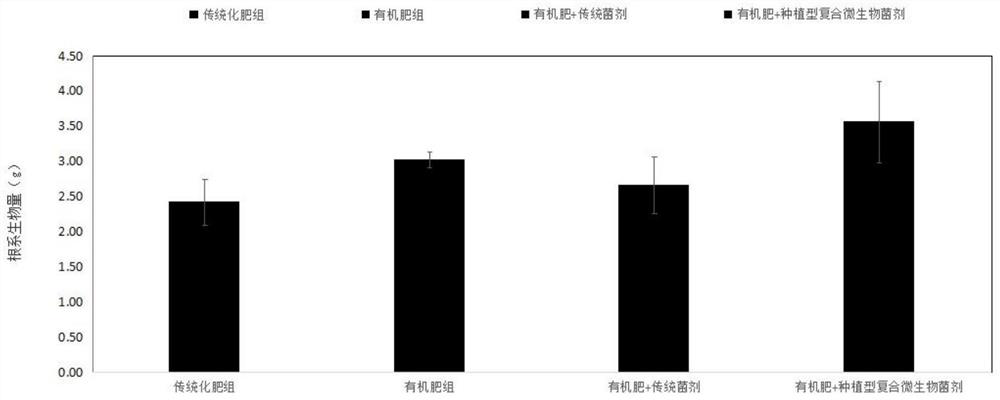

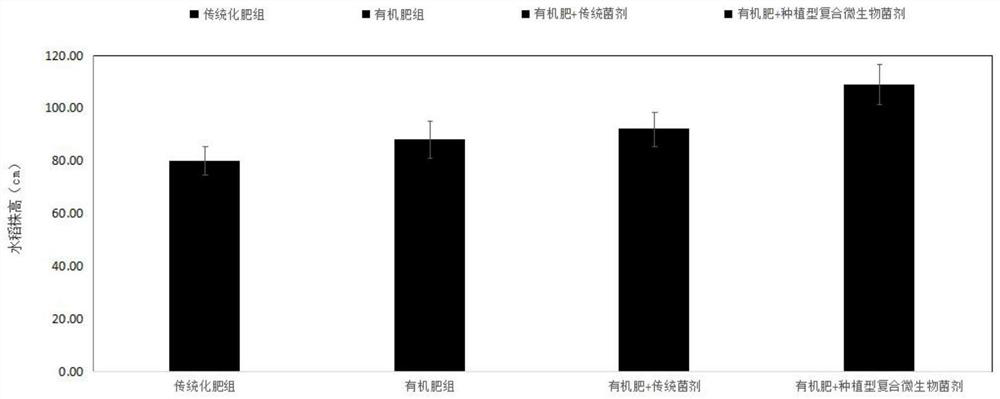

experiment example 1

[0065] Experiments were carried out in rice fields (50 mu) in Chongming District, and the addition plan of the combination of organic fertilizer and compound microbial agent was set:

[0066] Traditional chemical fertilizer group (as blank control group), according to the consumption of 750kg / mu, it is applied in the conventional fertilization period;

[0067] Organic fertilizer addition group, organic fertilizer was purchased from Zhejiang Weimeisi Agriculture and Animal Husbandry Co., Ltd., and was applied in the conventional fertilization period according to the amount of 750kg / mu;

[0068] Organic fertilizer+planting type compound microbial inoculum group, organic fertilizer is the same as organic fertilizer adding group, planting type compound microbial inoculum adding group uses the compound microbial inoculum method in embodiment 1;

[0069] Organic fertilizer + traditional microbial agent group, organic fertilizer and organic fertilizer added group, the traditional mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com