Transverse partition plate for controlling welding shrinkage and cross slope precision and manufacturing method thereof

A manufacturing method and a technology for transverse diaphragms, which are applied to bridge parts, bridges, buildings, etc., can solve problems such as poor assembly accuracy of plate units and difficulty in controlling the accuracy of bridge deck cross slopes, and achieve shrinkage and deformation of U-rib notch spacing, Improve safety and service life, and meet the effect of smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

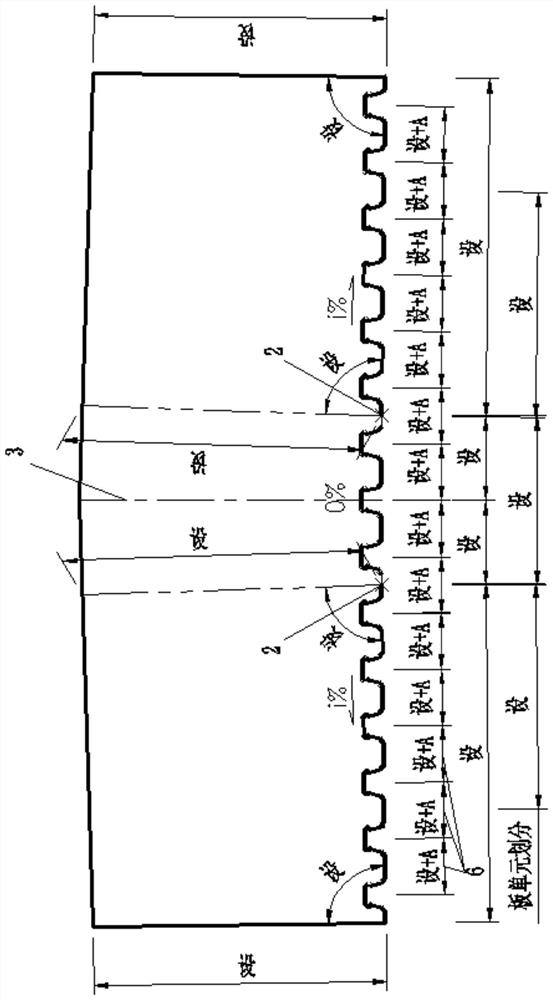

[0031] Embodiment 1: In step S002, when the deck width of the steel box girder is 50m-70m, and the number of transverse blocks of the roof or floor is 20-30, i=0.13.

Embodiment 2

[0032] Embodiment 2: In step S002, when the width of the steel box girder deck is 40m-50m, and the number of transverse blocks of the roof or floor is 15-20, i=0.12.

[0033] Among them, it needs to be explained that: when the width of the steel box girder deck is 50m, and the number of transverse blocks of the top or bottom slab is 20, i=0.13 or i=0.12.

Embodiment 3

[0034] Embodiment 3: In step S002, when the deck width of the steel box girder is 25m-40m, and the number of transverse blocks of the roof or floor is 10-15, i=0.11.

[0035] It should be noted that: when the width of the steel box girder deck is 40m, and the number of transverse blocks on the top or bottom slab is 15, i=0.12 or i=0.11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com