Conveying system facilitating machining of water pump accessories

A technology of conveying system and accessories, applied in the field of conveying system, can solve the problems such as the inability to guarantee the efficient operation of the conveying system, the inability to fully enclosed protection of hinges, the inconvenience of site transfer and transportation, etc., so as to ensure normal use and operation, facilitate site transfer, Easy and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

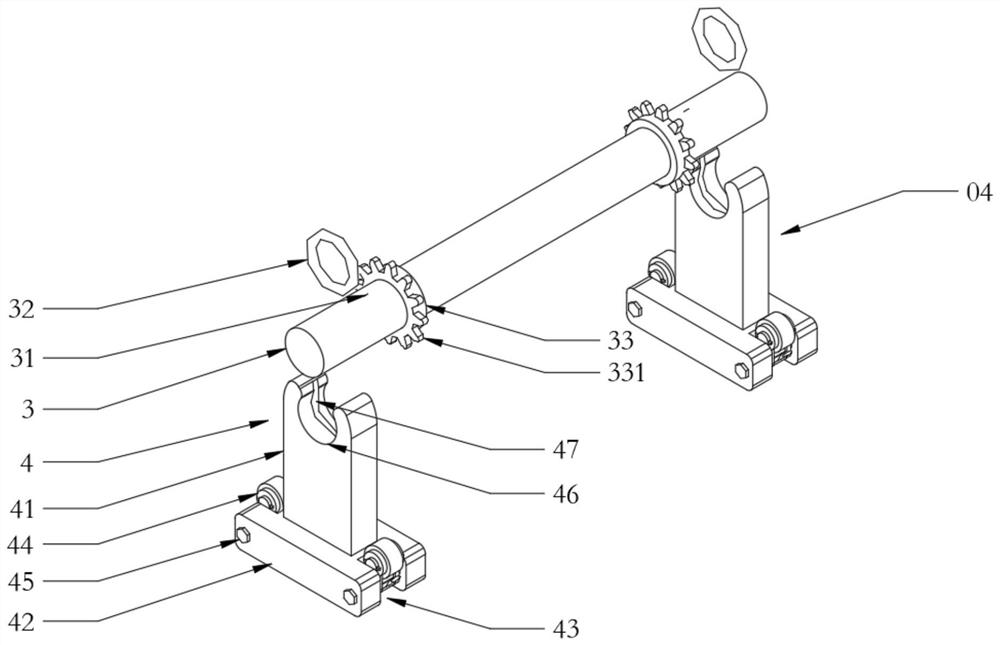

[0030] see Figure 1-9 , the present invention provides a technical solution for the conveying system that facilitates the processing of water pump accessories: it includes a conveying assembly 01, a transmission mechanism 1 for conveying accessories is provided in the middle of the conveying assembly 01, and a number one for supporting the bottom of the system is provided on both sides of the transmission mechanism 1. The supporting leg assembly 4 and the No. 2 supporting leg assembly 04, the two sides of the transmission mechanism 1 are provided with the No. 1 shield 2 and the No. 2 shield 02 for protecting the internal transmission structure. Connected No. 1 shaft 3 and No. 2 shaft 03, No. 1 shroud 2 and No. 2 shroud 02 are equipped with No. 1 cylinder part 5 and No. 2 trumpet part 05 for holding defective products;

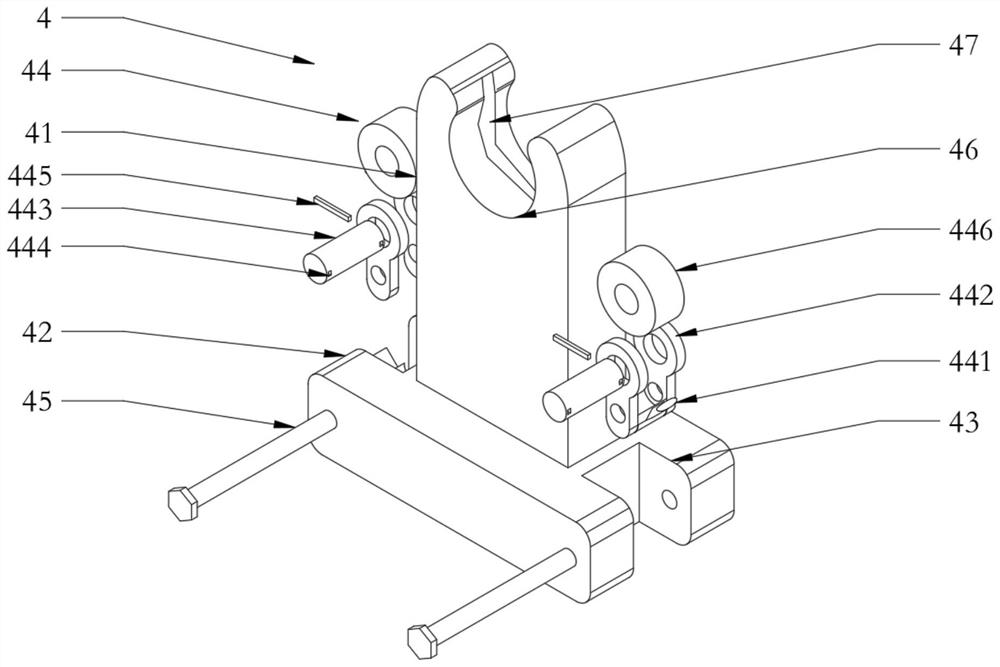

[0031] Such as Figure 1-4 As shown, the No. 1 foot assembly 4 includes a foot plate 41 for providing vertical support force, one end of the foot plate 41 is...

Embodiment 2

[0034] Such as Figure 1-9 As shown, it includes the conveying assembly 01. The middle part of the conveying assembly 01 is provided with a conveying mechanism 1 for conveying accessories, and the two sides of the conveying mechanism 1 are provided with a No. 1 leg assembly 4 and a No. 2 leg assembly 04 for supporting the bottom of the system. The two sides of the transmission mechanism 1 are provided with the first shield 2 and the second shield 02 for protecting the internal transmission structure, and the inner two ends of the transmission mechanism 1 are symmetrically provided with the first shaft 3 and the second shaft for transmission connection 03. Both sides of one end of No. 1 shield 2 and No. 2 shield 02 are installed with No. 1 cylinder part 5 and No. 2 cylinder part 05 for containing defective products;

[0035] Such as Figure 5-6 As shown, the No. 2 shield 02 includes an inner cover plate 021 for providing protection. The two inner sides of the inner cover plate...

Embodiment 3

[0038] Such as Figure 1-9 As shown, it includes the conveying assembly 01. The middle part of the conveying assembly 01 is provided with a conveying mechanism 1 for conveying accessories, and the two sides of the conveying mechanism 1 are provided with a No. 1 leg assembly 4 and a No. 2 leg assembly 04 for supporting the bottom of the system. The two sides of the transmission mechanism 1 are provided with the first shield 2 and the second shield 02 for protecting the internal transmission structure, and the inner two ends of the transmission mechanism 1 are symmetrically provided with the first shaft 3 and the second shaft for transmission connection 03. Both sides of one end of No. 1 shield 2 and No. 2 shield 02 are installed with No. 1 cylinder part 5 and No. 2 cylinder part 05 for containing defective products;

[0039] Such as Figure 6-7 As shown, the inner side of the No. 2 shield 02 is located on one side of the No. 2 shaft 03 and a No. 1 baffle 6 is installed. One en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com