Method for identifying side form based on 2D plane vision and form removal equipment

A visual recognition and side mold technology, which is used in auxiliary molding equipment, unloading devices, ceramic molding machines, etc., can solve the problems of labor, low efficiency, and reduced mold removal efficiency, saving work time, improving recognition ability, and improving The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

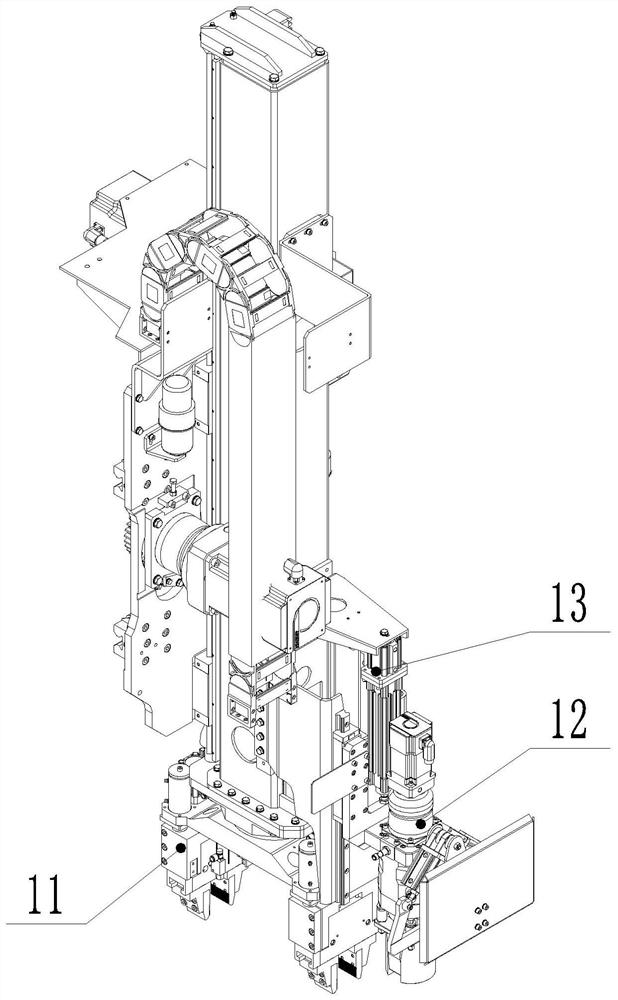

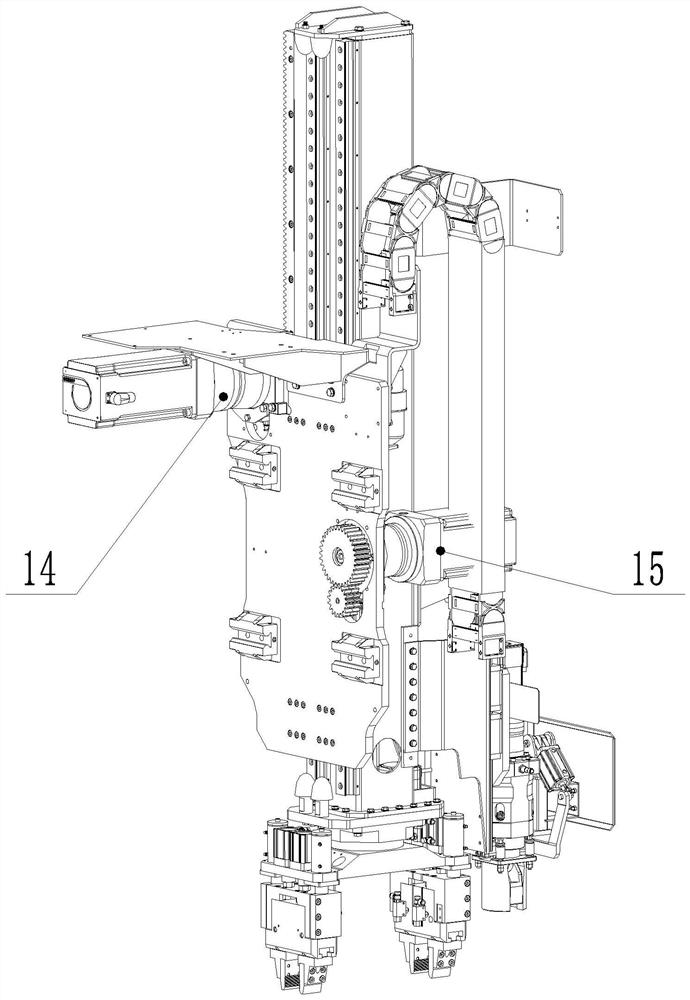

[0032] Such as Figure 1-5 As shown, a formwork removal device based on 2D visual recognition of side forms includes a formwork removal manipulator 1, an area array camera 2, and a strobe light source 3. The formwork removal manipulator 1 includes a formwork removal manipulator jaw group 11 and a magnetic nail pulling mechanism 12. Lifting cylinder group 13, vertical transmission mechanism 14, horizontal transmission mechanism 15, area array camera 2, stroboscopic light source 3 are used in conjunction to irradiate and photograph the mold table 4, and the longitudinal transmission mechanism 14 is used to drive The demolition manipulator 1 moves longitudinally on the beam of the demolding equipment, the transverse transmission mechanism 15 is used to drive the demolding manipulator 1 to move laterally on the beam of the demolding equipment, the jaw group 11 of the demolding manipulator is used to grip the side formwork 5, and The gripper group 11 of the manipulator includes a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com