Remote control electric vehicle hook multifunctional operation machine and use method thereof

A multi-functional, operating machine technology, applied to other manufacturing equipment/tools, lifting devices, lifting frames, etc., can solve the problem of single function of maintenance equipment, achieve the effect of optimizing the working environment, strong trafficability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

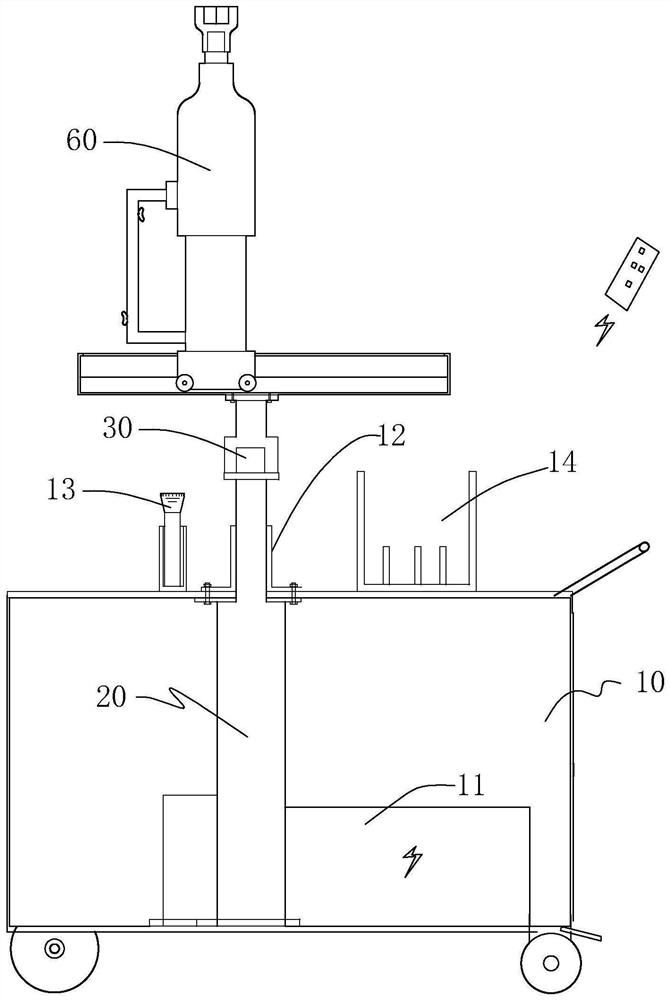

[0045] The car body assembly 10 of this equipment is a cuboid structure composed of a frame welded by square steel pipes and a shell welded by stainless steel plates. The interior has a hollow structure for installing the lifting assembly 20, the control circuit and the rechargeable power battery 11.

[0046] The control circuit adopts a single-chip microcomputer module, which is installed in the above-mentioned cavity, and is used in conjunction with the hand-held remote controller, which is safe and reliable.

[0047] This machine equipment uses 24V rechargeable lithium power battery, which belongs to green new energy, avoids the risk of personal injury and ensures safe production

[0048] Lifting assembly 20, used in conjunction with the above, adopts an electric lifting assembly, one of the preferred methods. In this embodiment, an electric lifting push rod is used. The electric lifting push rod is installed vertically, and the lower end is fixed on the car body. on the fr...

Embodiment 2

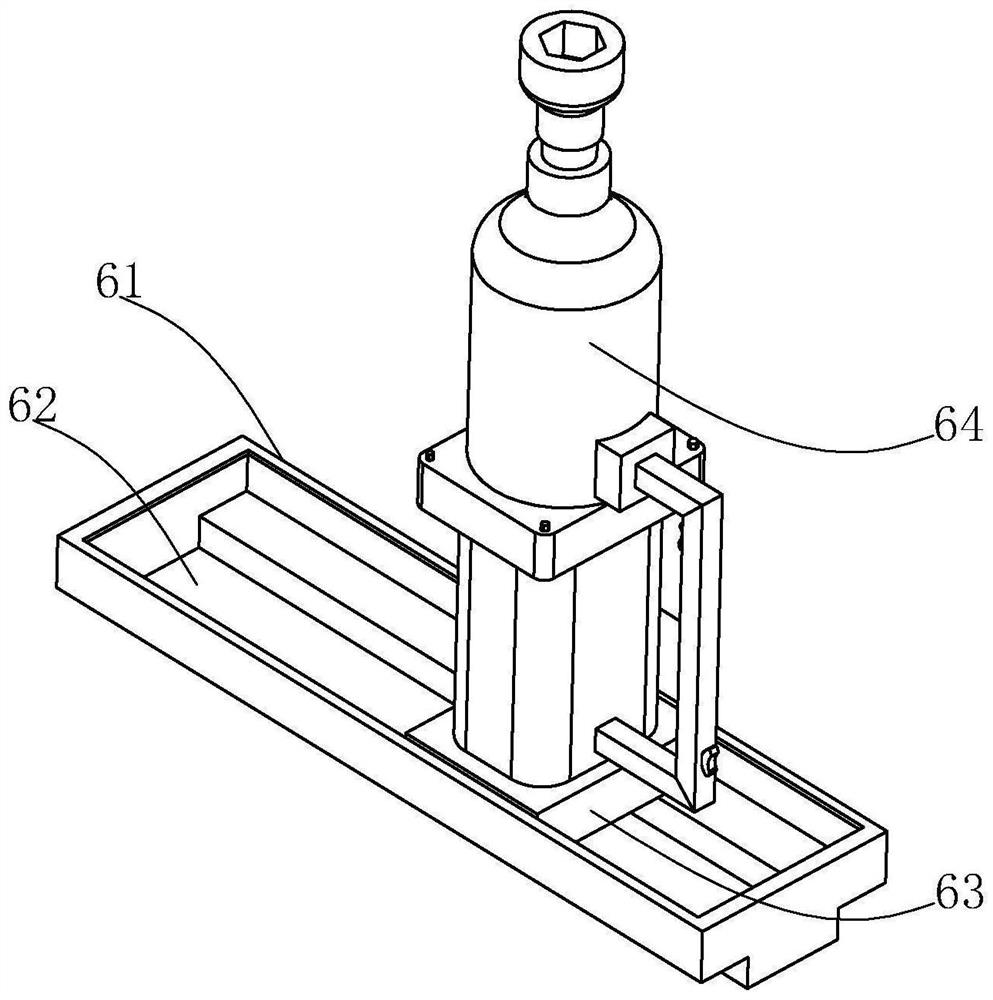

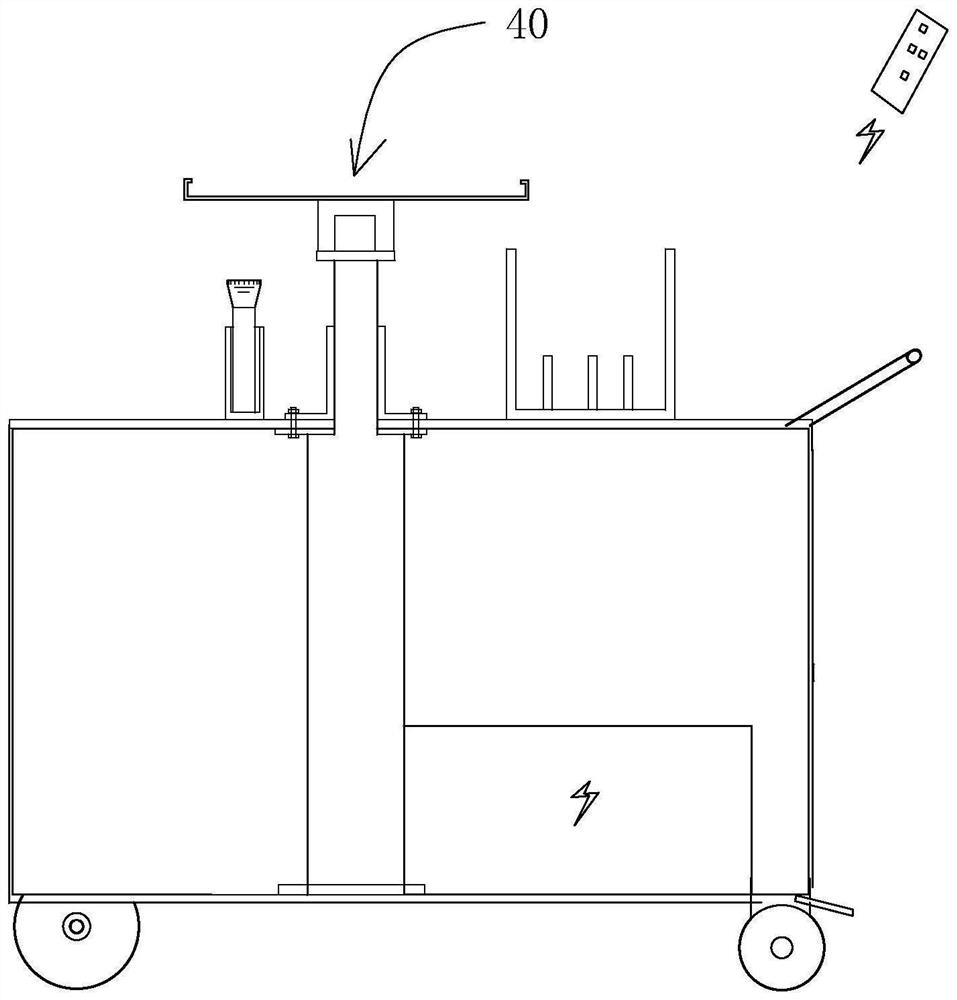

[0079] This embodiment is based on an improvement of Embodiment 1, specifically, it is an improvement for the lifting assembly 20, and the electric lifting push rods in the lifting assembly are set to two, that is, through two vertically arranged The electric lifting push rods with the same specifications perform jacking operations on the coupler limit baffle welding repair positioning module 40, the coupler round pin support plate disassembly module 50 or the coupler bolt disassembly module 60 installed on it. Example 1, this embodiment further enhances the stability of the operation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com