Double-cavity steel slag treating drum mechanism

A processing device and drum technology, applied in the direction of recycling technology, etc., can solve the problems of troublesome cleaning of diverter block residues, etc., and achieve the effect of improving the effect of steel slag processing and simplifying the transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

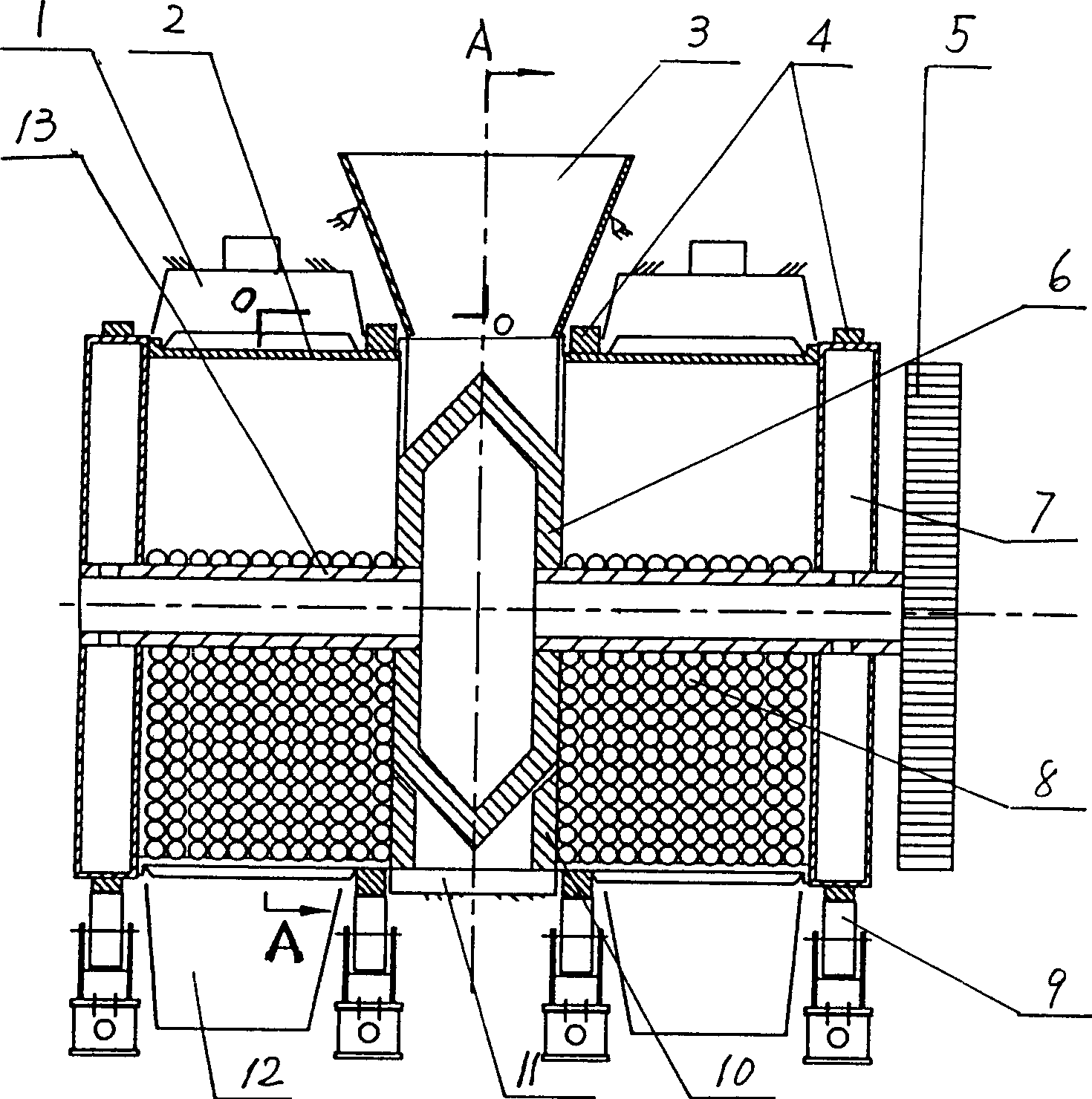

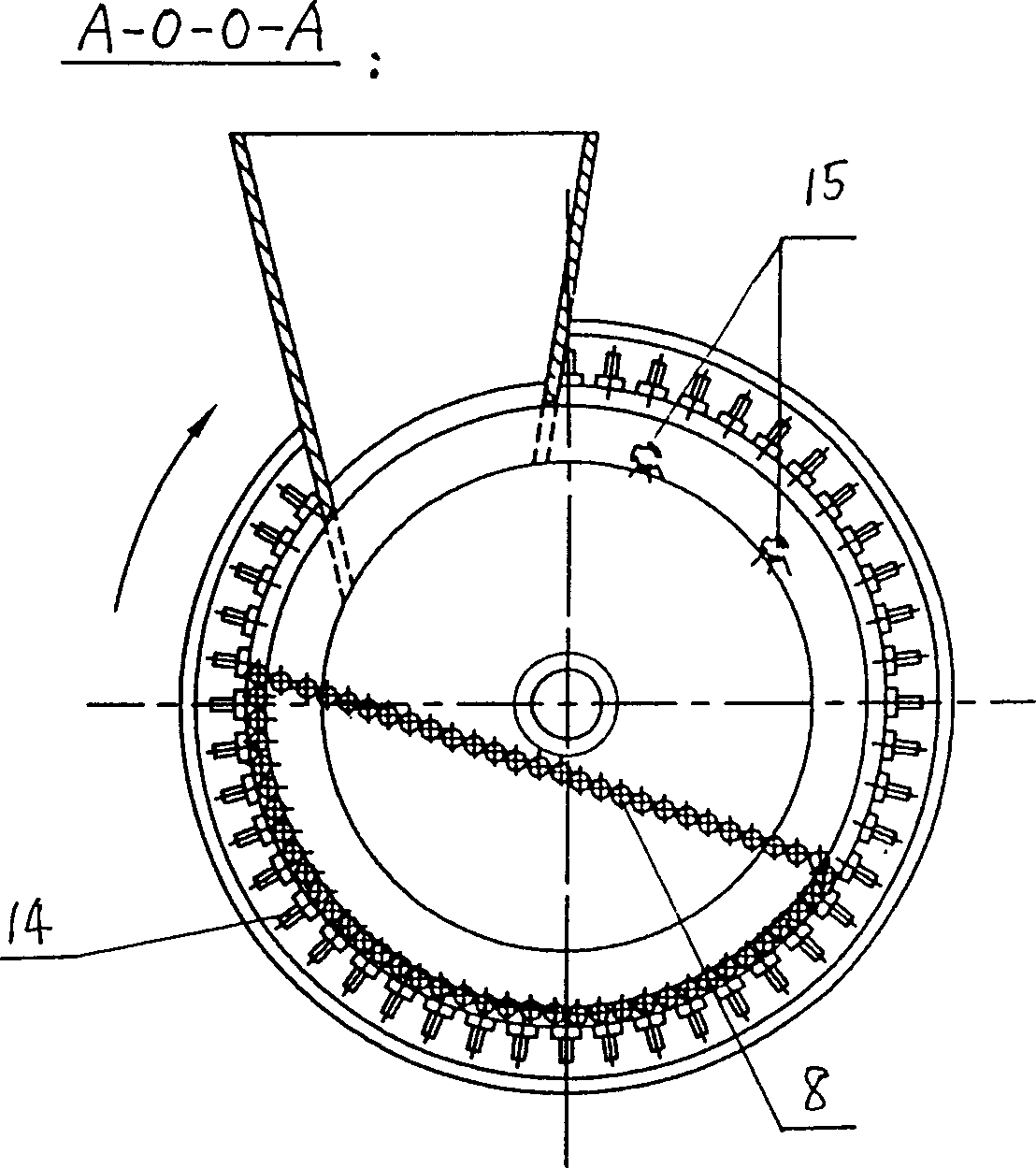

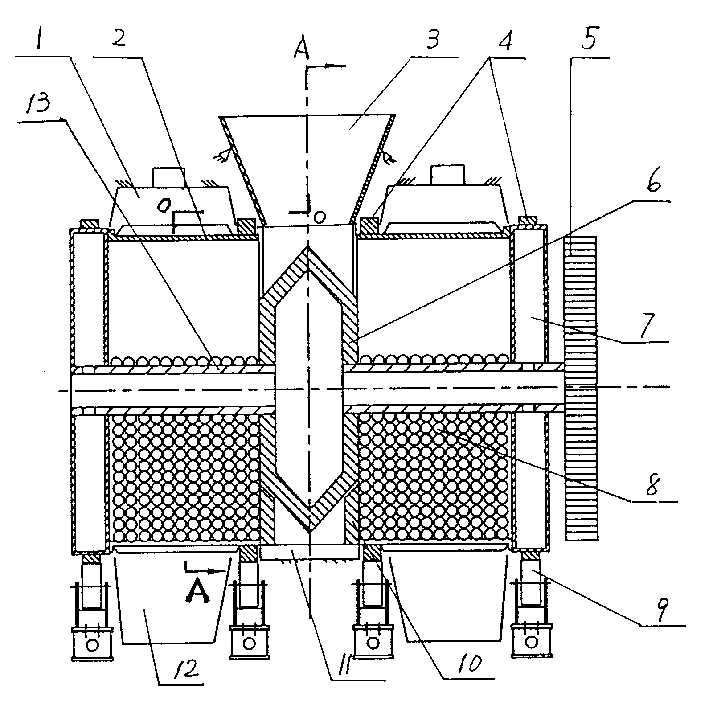

[0012] A best embodiment of the present invention is: see figure 1 and 2 The double-chamber drum steel slag processing device includes two squirrel-cage drums 2 that are partially filled with steel balls 8 in the cavity and are arranged opposite to each other on the same axis. Ring 11, a rotating splitter plate 6 is installed in the inner cavity of the fixed ring 11, the rotating shaft 13 of the splitting disc is coaxial with the drum 2, and is fixedly connected with the water cooling box 7 at the end of the drum 2, and an outer part of the rotating shaft 13 The end is fixedly connected with a transmission bull gear 5. The diverter plate 6 and its rotating shaft 13 are both hollow bodies, and the inner cavity thereof communicates with the inner cavity of the water-cooled box body 7 . There is an opening above the fixed ring 11, and its opening is slightly off to one side so that the steel slag has a longer rolling stroke in the drum 2, and a funnel 3 is inserted into the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com