Improved assembled steel structure shed tunnel

A steel structure and assembled technology, which is applied in the field of sheds and caves, can solve the problems of affecting the safe operation of railways, short service life, and damage, and achieve the effects of low construction and construction costs, improving safe operation, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

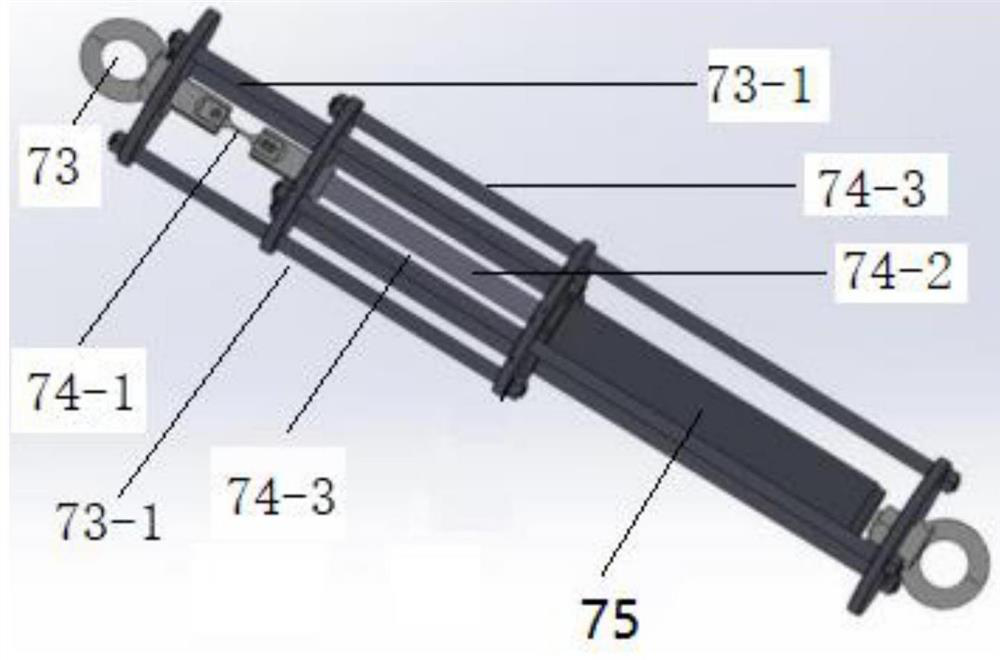

[0030] An assembled steel structure shed hole provided in this embodiment, such as figure 1 As shown, the vertical column 1 is arranged on both sides of the tunnel 6, and the beam 3 and the column 1 at the top of the column 1 form a door frame unit, and the longitudinal beams perpendicular to the beam 3 are arranged between the adjacent door frame units. It includes the main longitudinal beam 2 arranged in the middle of the beam 3 and the auxiliary longitudinal beams 4 at both ends of the beam 3, side beams 5 are arranged between adjacent columns 1; beams are arranged between the longitudinal beams; the roof of the shed hole is made of longitudinal beams The grid-like "roof" composed of beams and beams is provided with steel plates, waterproof layers and energy-absorbing layers in sequence. The longitudinal beams and / or transverse beams are provided with energy-absorbing units 7 coaxial with the beams, preferably each longitudinal beam or transverse beam is provided with one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com