Anti-seepage structure for post-cast strip of outer wall

A post-casting and anti-leakage technology, which is applied to underwater structures, infrastructure engineering, building components, etc., can solve the problem of single and fixed baffle width, the inability to freely adjust the baffle width according to different needs, and flow to the rear Solve problems such as the casting belt area, achieve the effect of saving time and effort in disassembly, improving sealing performance, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

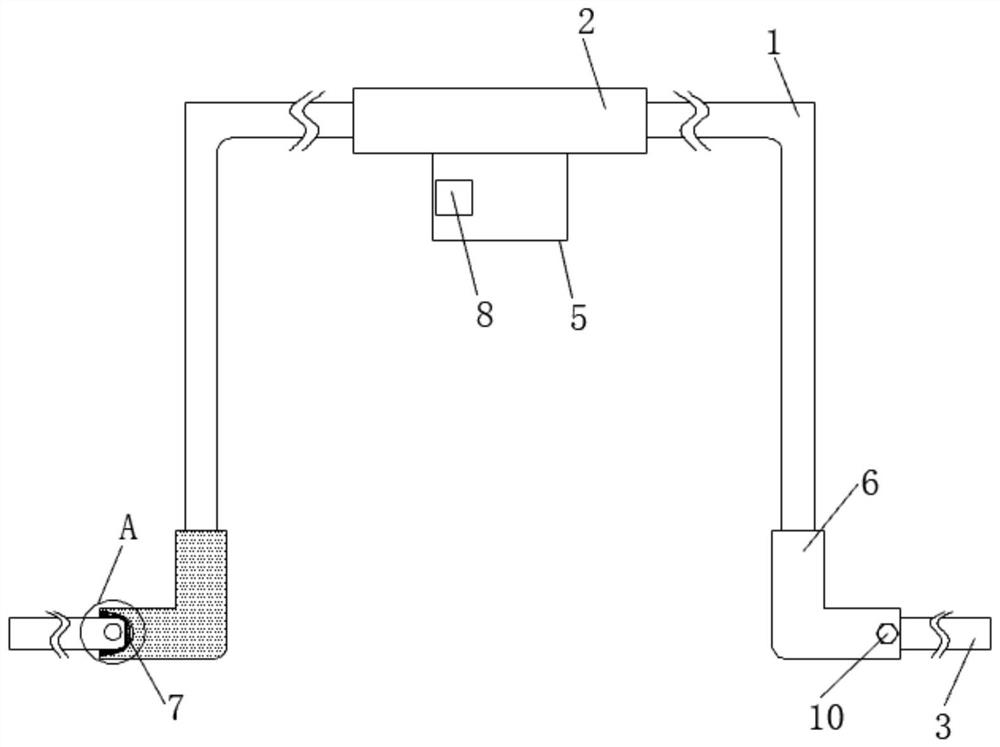

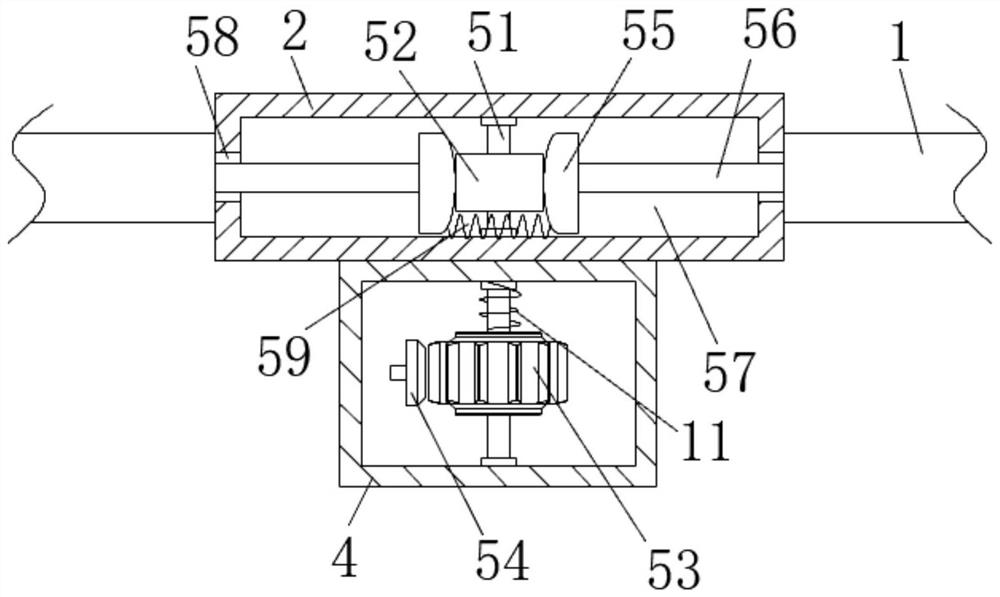

[0023] see Figure 1-5 , the present invention provides a technical solution: an anti-leakage structure of an exterior wall post-casting belt, including two L-shaped baffles 1, a horizontal plate 2 is arranged between the two L-shaped baffles 1, and one of the horizontal plates 2 The side is fixedly connected with the box body 4, the interior of the horizontal plate 2 is provided with a cavity 57, and the interior of the cavity 57 is provided with an adjustment component 5, and one end of the L-shaped baffle 1 is integrally formed with an L-shaped connecting column 6, and the L-shaped connecting column One end of 6 is inserted with a board 3, and an anti-seepage component 7 is arranged between the board 3 and the L-shaped connecting column 6.

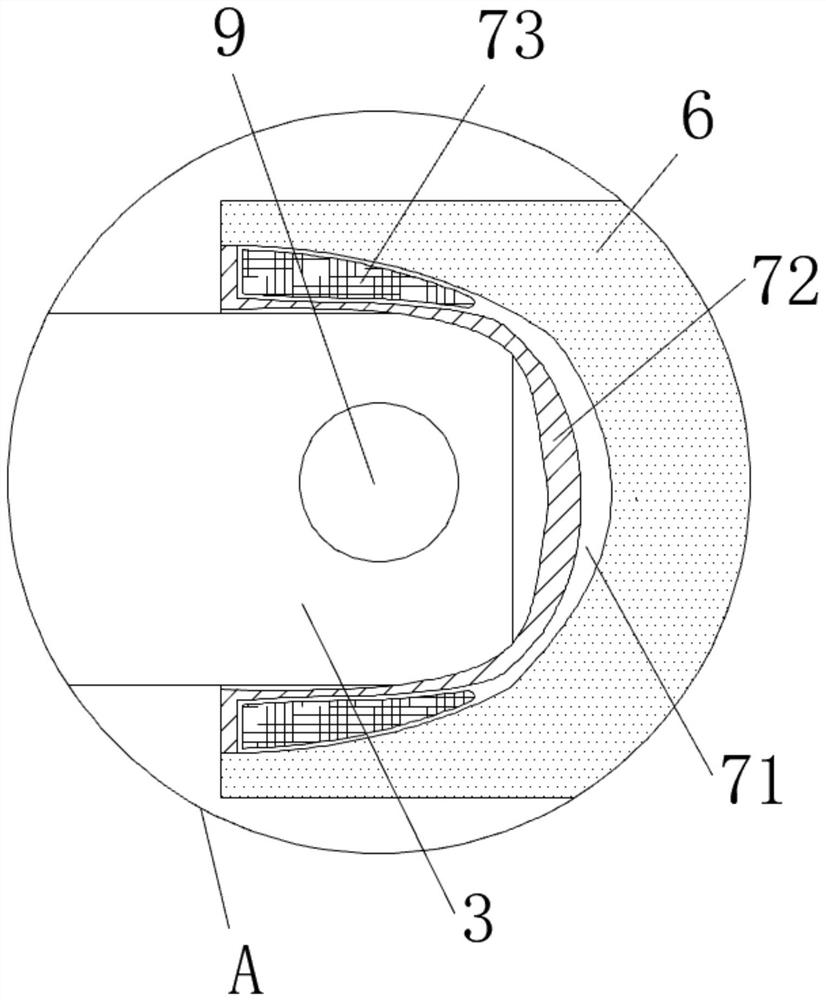

[0024] The anti-seepage component 7 includes a rubber sleeve 72. The rubber sleeve 72 is a tapered sleeve. One side of the L-shaped connecting column 6 is provided with a tapered groove 71. The rubber sleeve 72 is fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com