Low-prestress high-ductility mixed reinforced concrete pile and manufacturing method thereof

A technology of concrete piles and mixed reinforcement, applied in sheet pile walls, reinforced molding, construction, etc., can solve the problems of low bearing capacity, low prestress degree, poor ductility, etc., and achieve improved deformation capacity, high ductility, and improved resistance Effect of Hammer Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

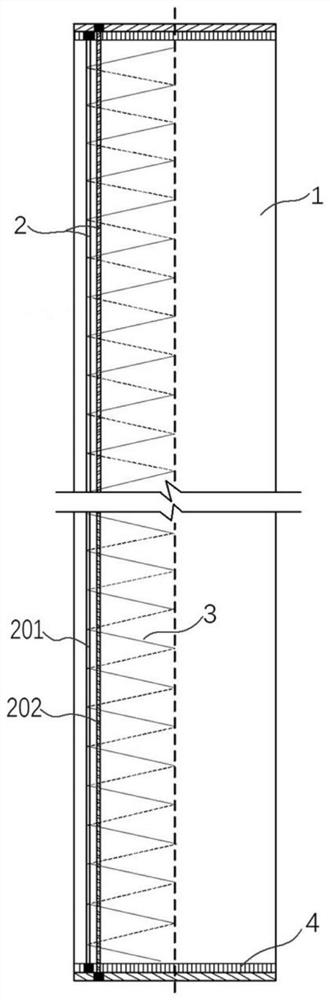

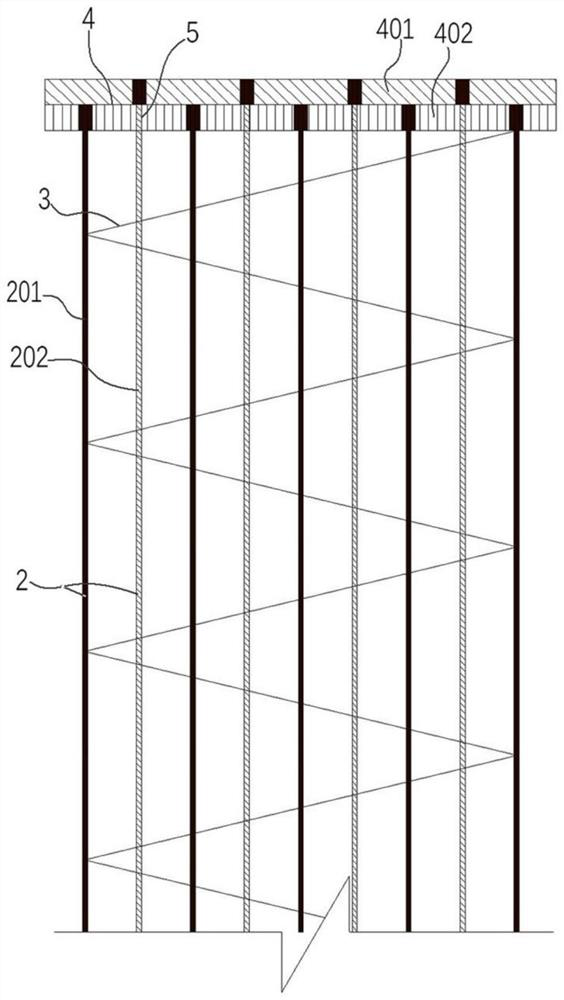

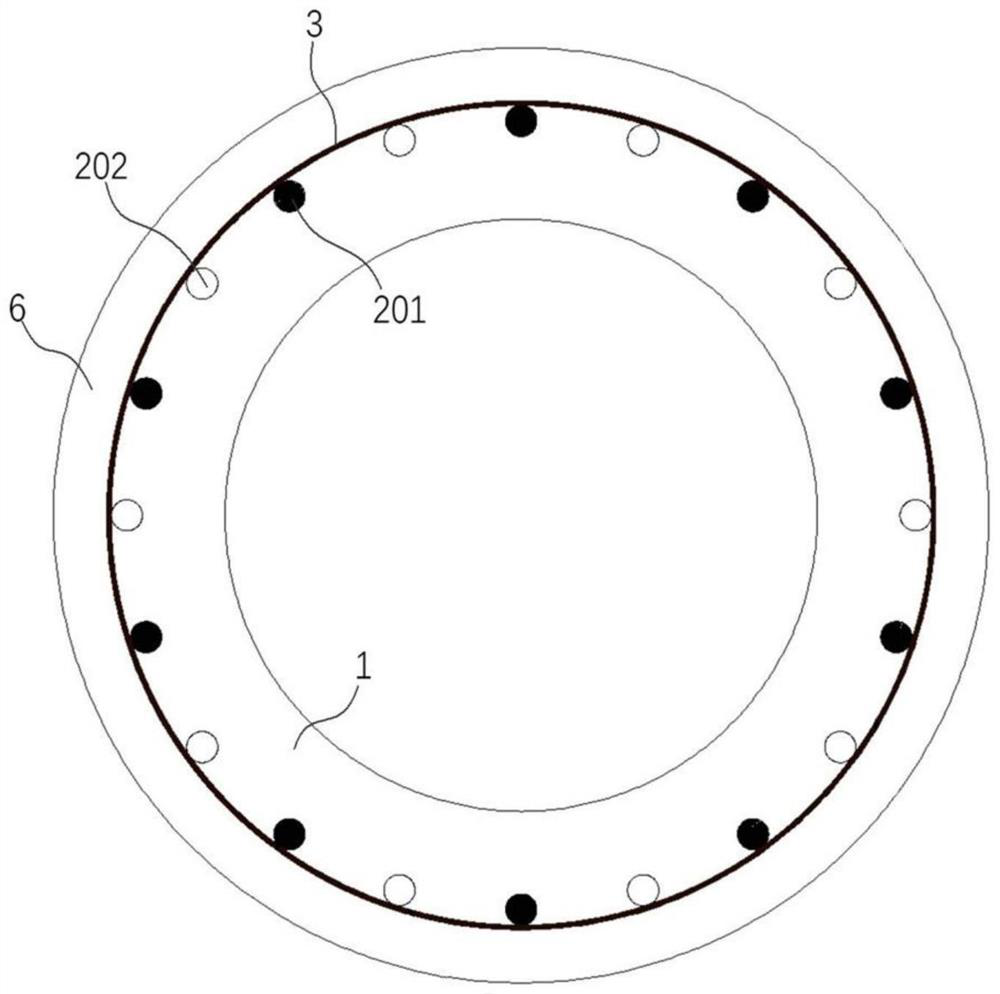

[0033] The mixed reinforced concrete pile with low prestress and high ductility in this embodiment solves the problems of low bearing capacity and poor ductility of traditional PHC concrete piles, and at the same time, compared with PRC mixed reinforced pipe piles, it can make full use of high-strength thermal tie ribs The deformation ability of the steel bar after yielding can improve the ductility and safety reserve of the component, so that it can be used more widely in the seismic fortification intensity area. For details, see Figure 1-Figure 4 , which mainly includes a concrete pile body. In this embodiment, the concrete pile body is casted with C105 grade concrete. The concrete pile body is a hollow tubular structure manufactured by a high-speed centrifugal process. In this embodiment, the cross-sectional shape of the concrete pile body is circular. The concrete pile body is provided with a reinforcement cage assembly whose section matches the shape of the concrete pil...

Embodiment 2

[0042] The same as embodiment 1 will not be repeated, the difference is: the stretching control stress σ of the prestressed steel rod by the tensioning equipment con Set to 0.6 times the standard value of its tensile strength f ptk , and fix the prestressed steel rods on the outer end plate. The tension control stress σ of the strength steel bar by the tensioning equipment con 0.6 times the standard value of yield strength f yk , and fix the strength steel bars on the inner end plate.

Embodiment 3

[0044] The same as embodiment 1 will not be repeated, the difference is: see Figure 4 , the concrete pile body is a hollow tubular structure made by a high-speed centrifugal process. In this embodiment, the cross-sectional shape of the concrete pile body is a hollow square, and the prestressed steel rod and strength steel bar are along the square hollow cross-section of the square pile. Layered intervals are uniformly distributed and fixed together with square stirrups to form the reinforcement cage assembly of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com