Water electrolysis hydrogen production device and method for multiple electrolytic cells

A technology for a hydrogen production device and an electrolytic cell, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of increasing the risk of hydrogen production, large variation range, and low balance accuracy, and achieve cost savings, increase gas production, Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present application will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, on the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form a new embodiment. .

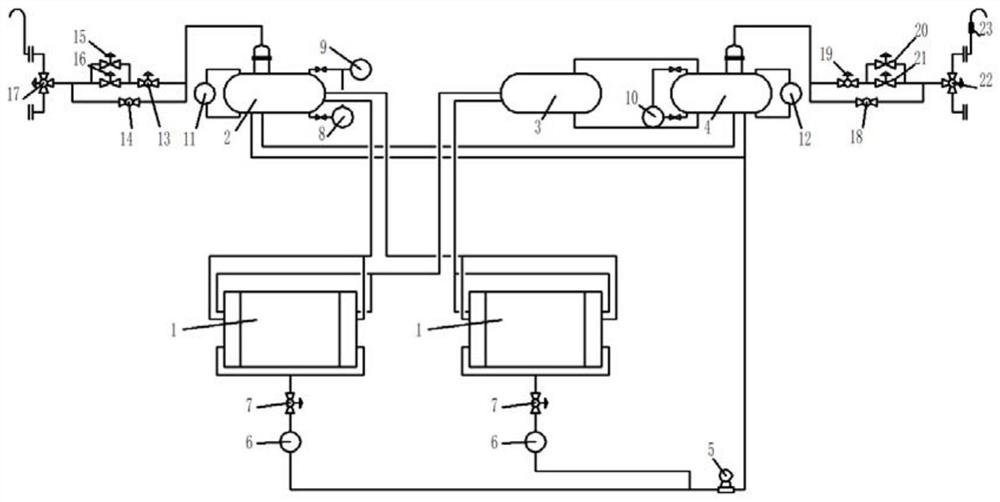

[0037] Please refer to figure 1 as shown, figure 1It is a flow chart of the hydrogen production control process by electrolysis of water according to an embodiment of the present invention. The electrolytic water hydrogen production device of the present invention includes a plurality of electrolytic cells 1, an oxygen separator 2, a hydrogen primary separator 3, a hydrogen secondary separator 4, a circulation pump 5, an oxygen side control device, a hydrogen side control device and lye flow control system. Each electrolyzer 1 adopts electrode electrolytic electrolyte to generate hydrogen and oxygen, wherein the electrolyte can be pure water, or KOH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com