Lightweight multifunctional composite material prepared from polyurethane and cork particles as well as preparation method and application of lightweight multifunctional composite material

A technology of cork particles and composite materials, which is applied in the fields of heat insulation, sound absorption and noise reduction, vibration and energy absorption, and can solve problems such as poor mechanical properties, narrow polyurethane sound absorption frequency band, and difficult porous materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

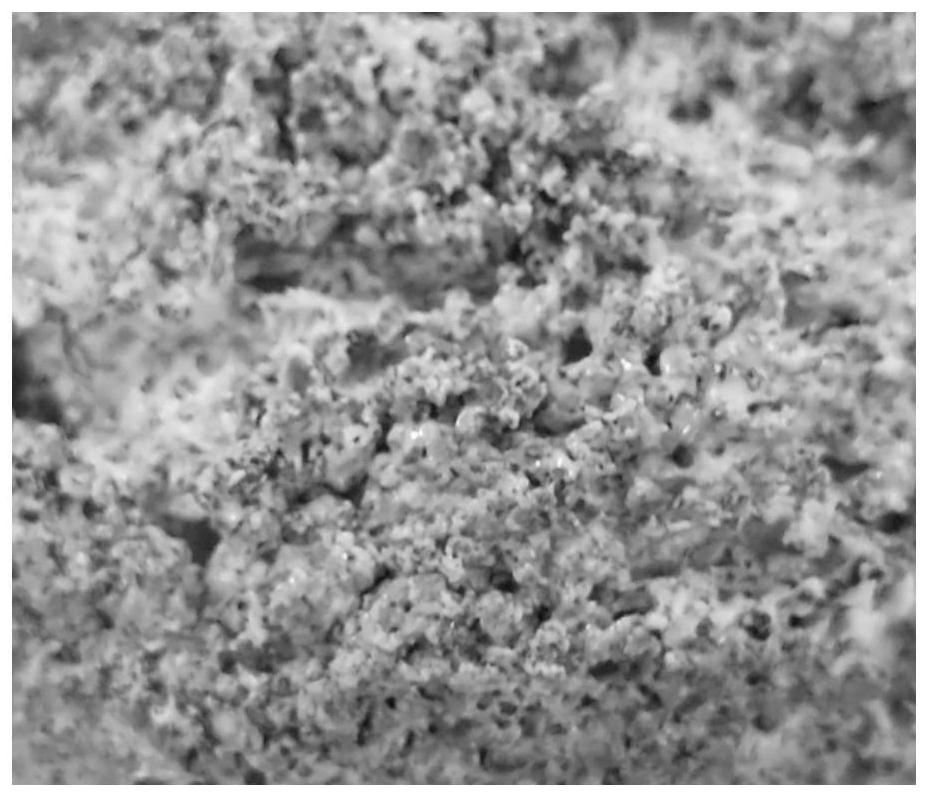

Image

Examples

Embodiment 1

[0041] 1) Use 4 mesh and 6 mesh standard sieves to screen the cork particles with a particle size of 3.4 to 4.8 mm, clean them, and the cork particles will be kept at an ambient humidity of 60.6% RH for a long time;

[0042] 2) Take 83.4 parts of the above-mentioned cork particles, lay them flat in the mold and place them in an electric heating constant temperature drying box with a power of 2000W for heat treatment, set the temperature at 120°C, and take out the cork particles after 10 hours of heat treatment;

[0043] 3) Measure the surface temperature of the cork particles at 43.4°C, add 8.3 parts of polyurethane black material into the mold, stir and mix thoroughly, and stir for 5 minutes to ensure that the surface of the cork particles is attached to the polyurethane black material to obtain a mixed material. Measure the surface temperature at 34.3°C, and the environment Temperature 26.4°C;

[0044] 4) Pour 8.3 parts of polyurethane white material into the mold, stir quickl...

Embodiment 2

[0049] 1) Use 4 mesh and 6 mesh standard sieves to screen the cork particles with a particle size of 3.4 to 4.8 mm, clean them, and the long-term environmental humidity of the cork particles is 61.6% RH;

[0050] 2) Take 85.7 parts of the above-mentioned cork particles, lay them flat in the mold and place them in an electric heating constant temperature drying box with a power of 2000W for heat treatment, set the temperature at 120°C, and take out the cork particles after 10 hours of heat treatment;

[0051] 3) Measure the surface temperature of the cork particles at 45.4°C, add 5.7 parts of polyurethane white material into the mold, fully stir and mix, and stir for 10 minutes to ensure that the surface of the cork particles is attached to the polyurethane white material to obtain a mixed material. The measured surface temperature is 35.3°C, and the ambient temperature 26.4°C;

[0052] 4) Pour 18.6 parts of polyurethane black material into the mold, stir quickly and fully, sti...

Embodiment 3

[0057] 1) Use 16 mesh and 20 mesh standard sieves to screen cork particles with a particle size of 0.8 to 1.2 mm, clean them, and the long-term environmental humidity of cork particles is 63.2% RH;

[0058] 2) Take 82.8 parts of the above-mentioned cork particles, lay them flat in the mold and place them in an electric heating constant temperature drying box with a power of 2000W for heat treatment, set the temperature at 110°C, and take out the cork particles after 4 hours of heat treatment;

[0059] 3) Measure the surface temperature of the cork particles at 56.4°C, add 8.6 parts of polyurethane white material into the mold, fully stir and mix, and stir for 20 minutes to ensure that the surface of the cork particles is attached to the polyurethane white material to obtain a mixed material. The measured surface temperature is 33.3°C, and the ambient temperature 25.4°C;

[0060] 4) Pour 8.6 parts of polyurethane black material into the mold, stir quickly and fully, stir for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com