Automatic conveying system for construction waste

A technology of automatic transportation and construction waste, applied in the direction of garbage collection, construction waste recycling, recycling technology, etc., can solve the problems of brick wear, large space occupation, and high pipeline cost, and achieve automatic induction longitudinal transportation processing and improve convenience. Sex and flexibility, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

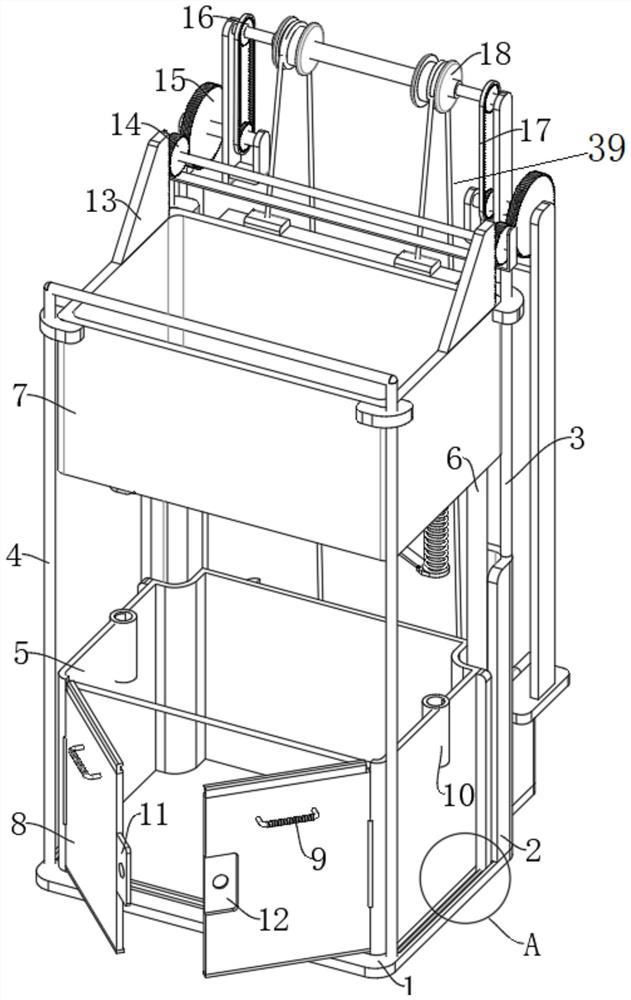

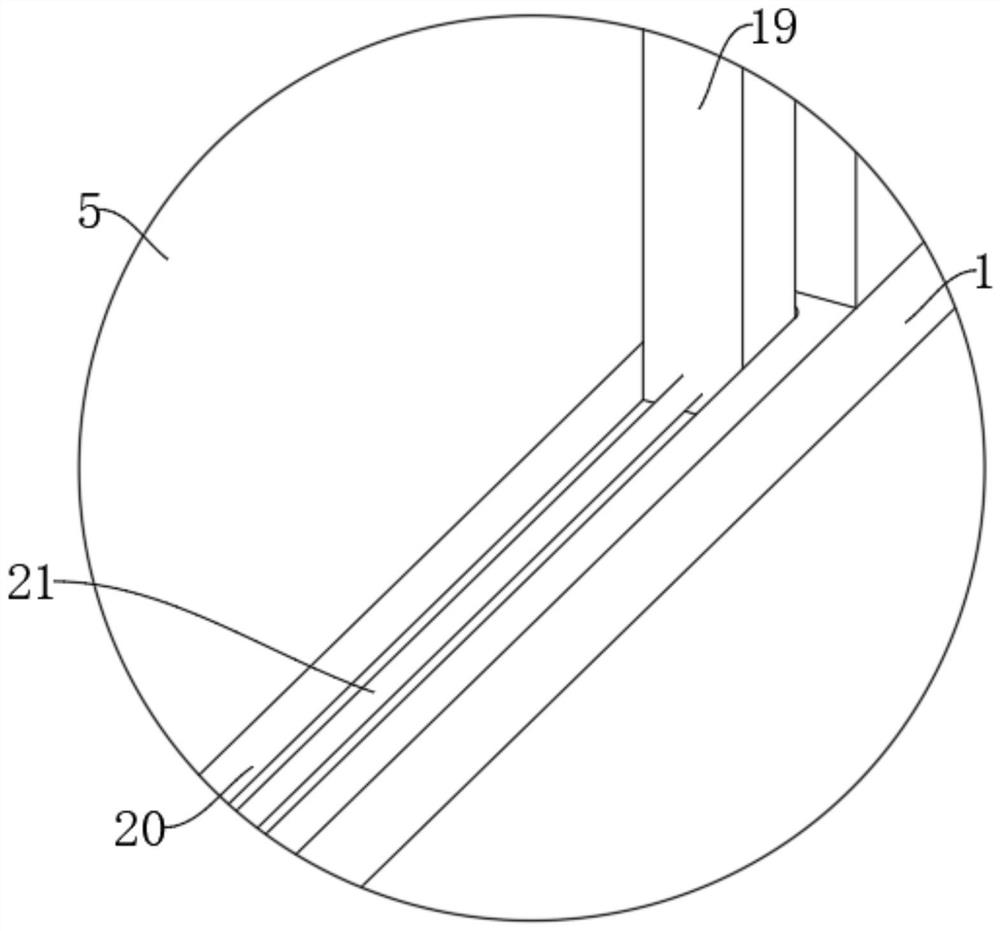

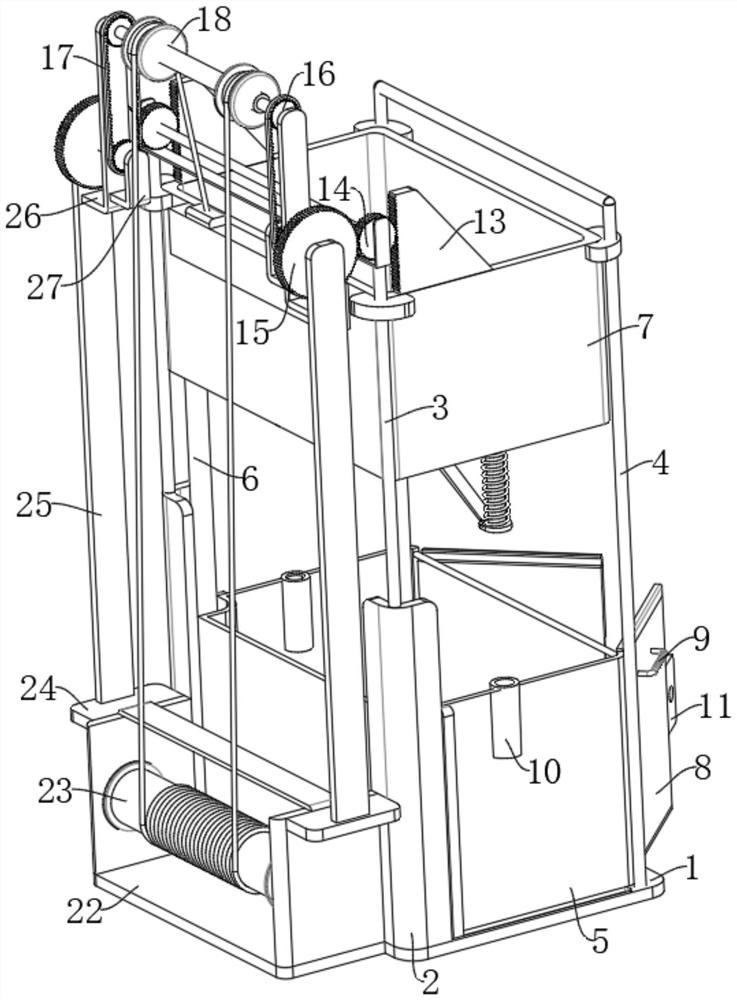

[0031] Please see attached figure 1 , attached image 3 And attached Figure 4, an automatic conveying system for construction waste, comprising a bottom plate 1, a support plate 2, a rear slide bar 3, a front slide bar 4, a storage box 5, a moving box 7, an inductive automatic lifting assembly, and an elastic automatic pulling assembly , convenient handling of sliding components and control components; a pair of support plates 2 are vertically connected to the two corners of the rear end of the bottom plate 1, a pair of rear slide bars 3 are vertically arranged on the pair of support plates 2 respectively, and a pair of The front sliding rods 4 are respectively vertically connected to the front two corners of the base plate 1; the storage box 5 is slidably arranged on the base plate 1 through a convenient handling sliding assembly; sliders a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com