Cooler welding device and using method thereof

A technology for welding devices and coolers, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult automatic welding of coolers and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

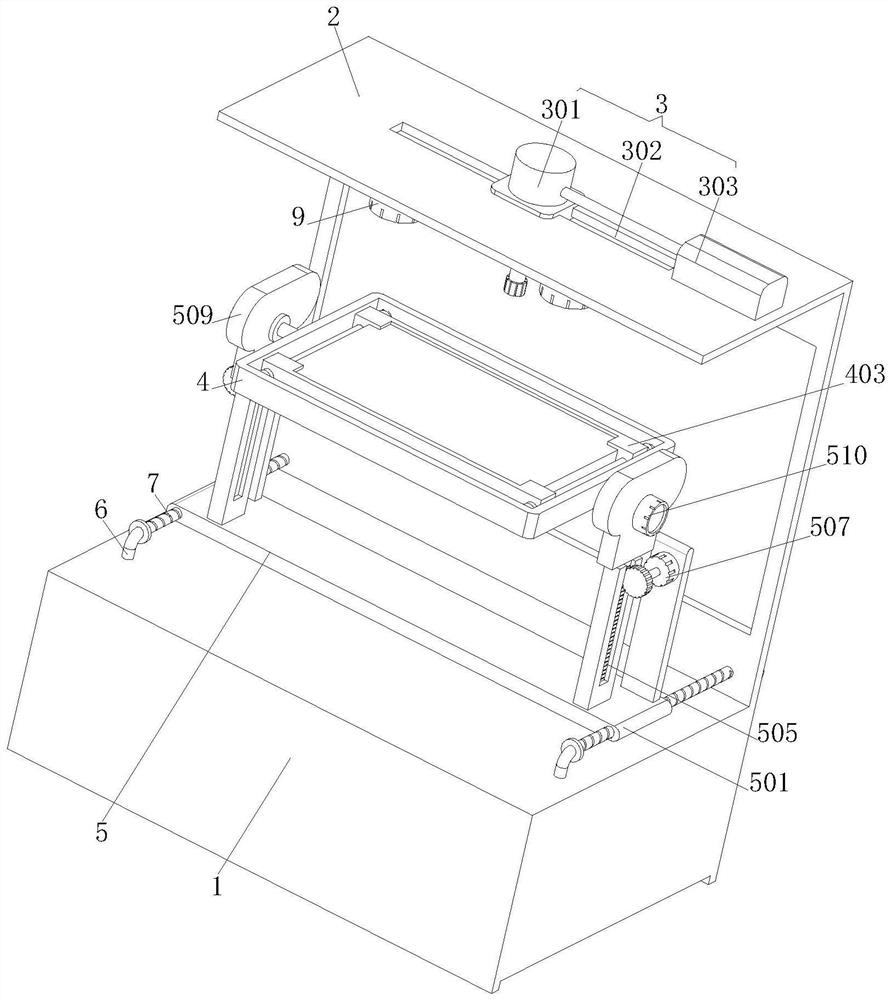

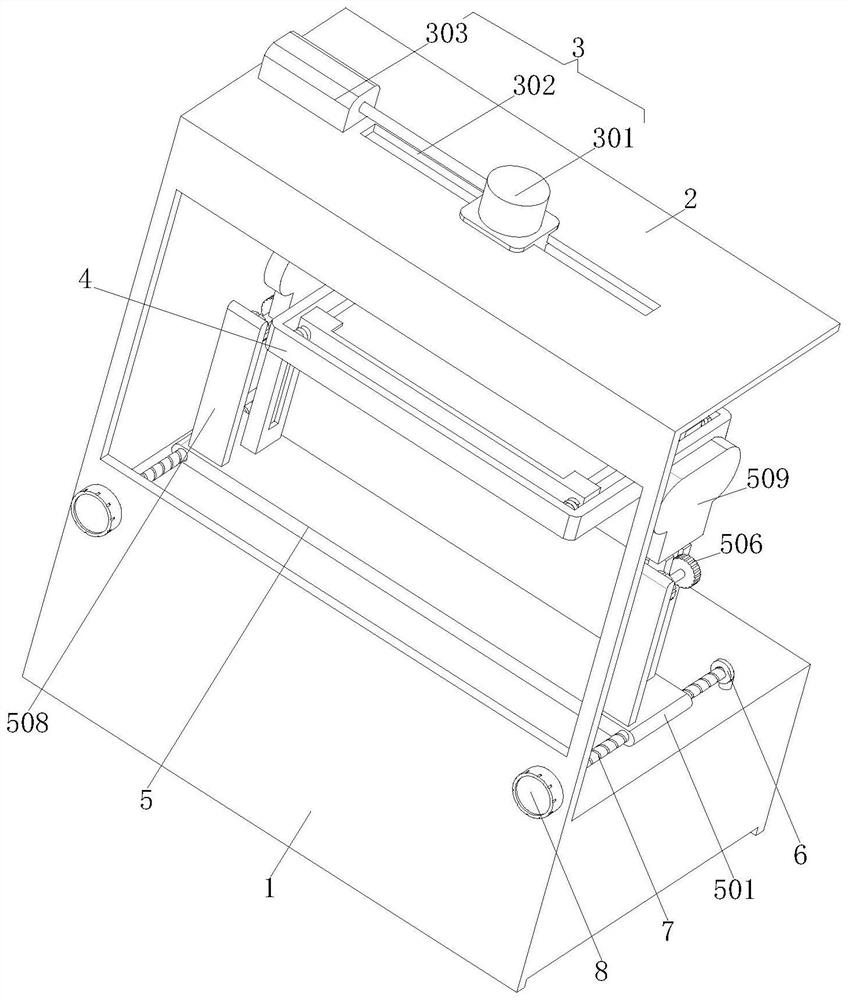

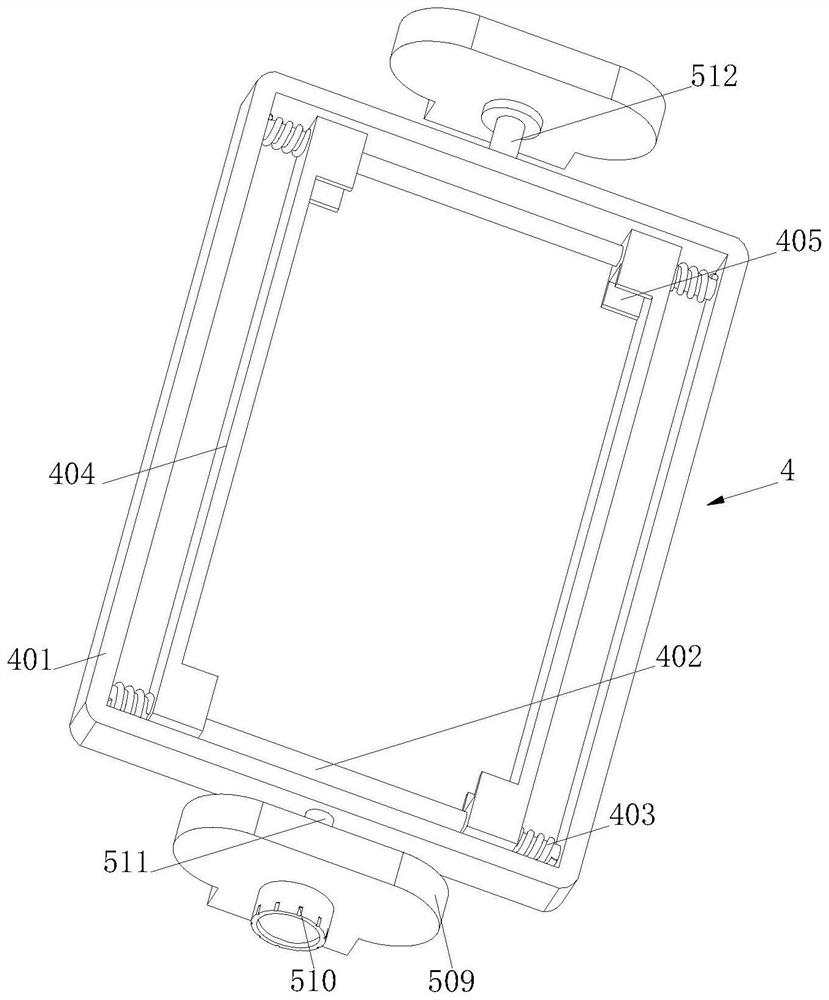

[0030] Such as Figure 1-5As shown, a cooler welding device proposed by an embodiment of the present invention includes a workbench 1, the top of the workbench 1 is connected with a fixed frame 2, and the inner top wall of the fixed frame 2 is provided with a linear reciprocating motion for the horizontal plane of the workpiece. The welding mechanism 3 is provided with a clamping mechanism 4 for positioning the workpiece under the welding mechanism 3, and the two sides of the clamping mechanism 4 are provided with an adjusting mechanism 5 for lifting or flipping in cooperation with the clamping mechanism 4. In the present invention The designed adjustment mechanism 5 can carry out vertical upward lifting movement or flipping movement respectively, and it is used in conjunction with the clamping mechanism 4. When the clamping mechanism 4 does the vertical upward lifting movement through the adjustment mechanism, the clamping mechanism 4 Before being transported to the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com