Sawtooth closed type construction method for cracking furnace area of large ethylene device

A technology of ethylene plant and construction method, which is applied in the field of zigzag occlusal construction in the pyrolysis furnace area of a large ethylene plant, can solve the problems of inability to use hoisting equipment, increase the radius of hoisting work, and increase the radius of hoisting work, so as to reduce the work radius, The effect of shortening the construction time and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

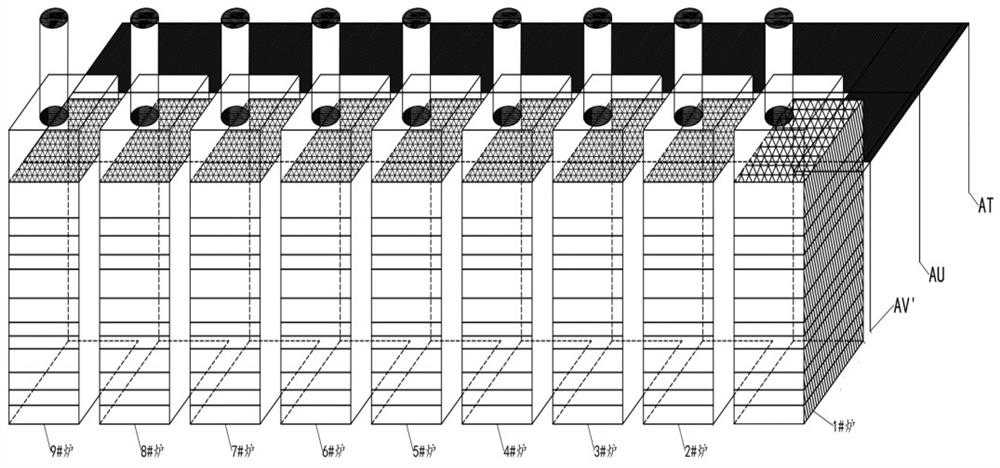

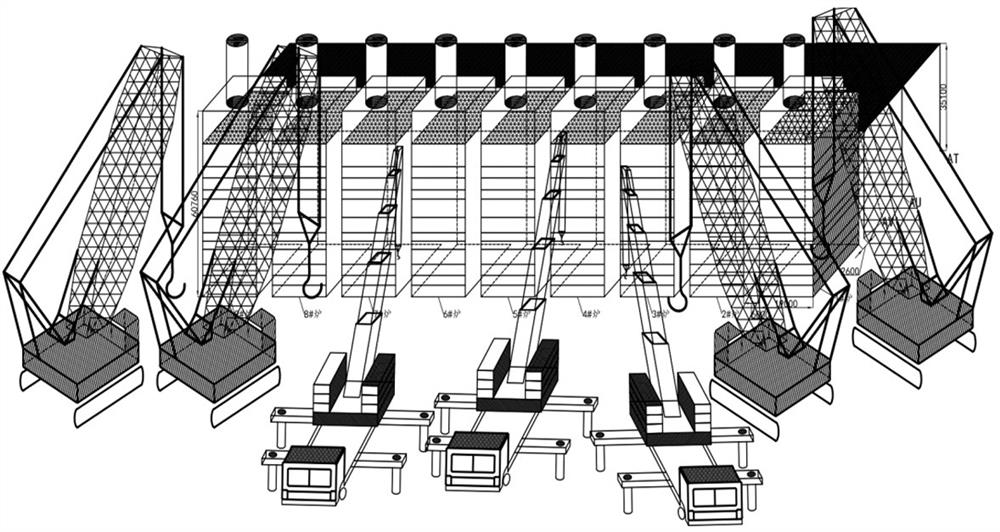

[0031] The present invention relates to a zigzag closed construction method in the pyrolysis furnace area of a large-scale ethylene plant. In a typical implementation, the construction method includes the following steps.

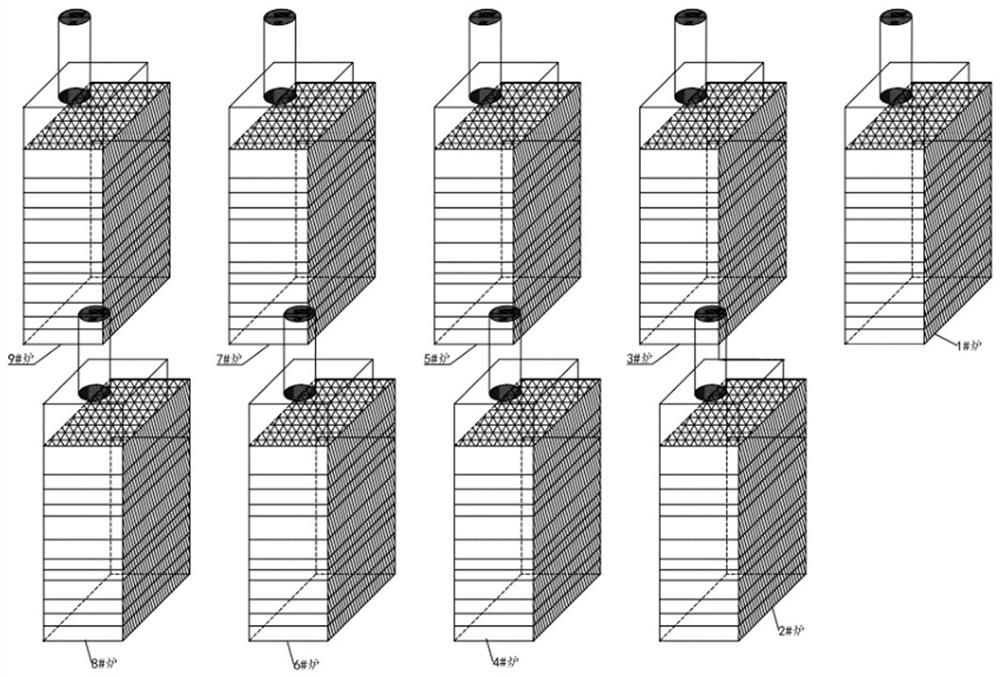

[0032] Step 1, divide the cracking furnaces numbered 1, 2, 3...n (n is an integer) installed side by side into the first construction group and the second construction group, the first construction group is the cracking furnaces with odd numbers, The second construction group is cracking furnaces with even numbers;

[0033] Step 2, the cracking furnace body in the first construction group is installed according to its installation position, and a zigzag interval is formed between the cracking furnaces;

[0034] Step 3, the cracking furnace in the second construction group is assembled to the furnace body in sections in the prefabrication site, and the pipelines on one or more sides of the cracking furnace in the second construction group are also installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com