Offshore heavy-load low-clearance luffing crane

A technology for cranes and low headroom, which is applied in cranes, transportation and packaging, etc. It can solve the problems of increasing the length of the arm body, increasing the operating range, unfavorable costs and safety control, etc., to reduce the cost of the luffing mechanism, increase the lifting height, The effect of enhancing work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

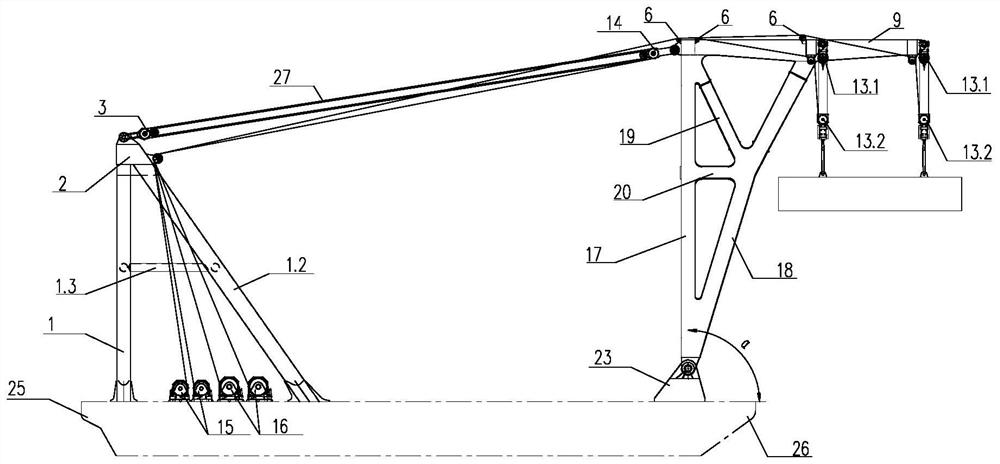

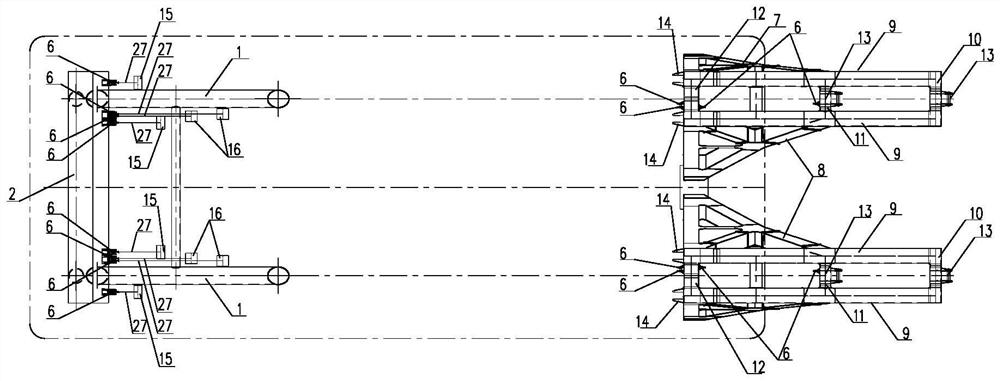

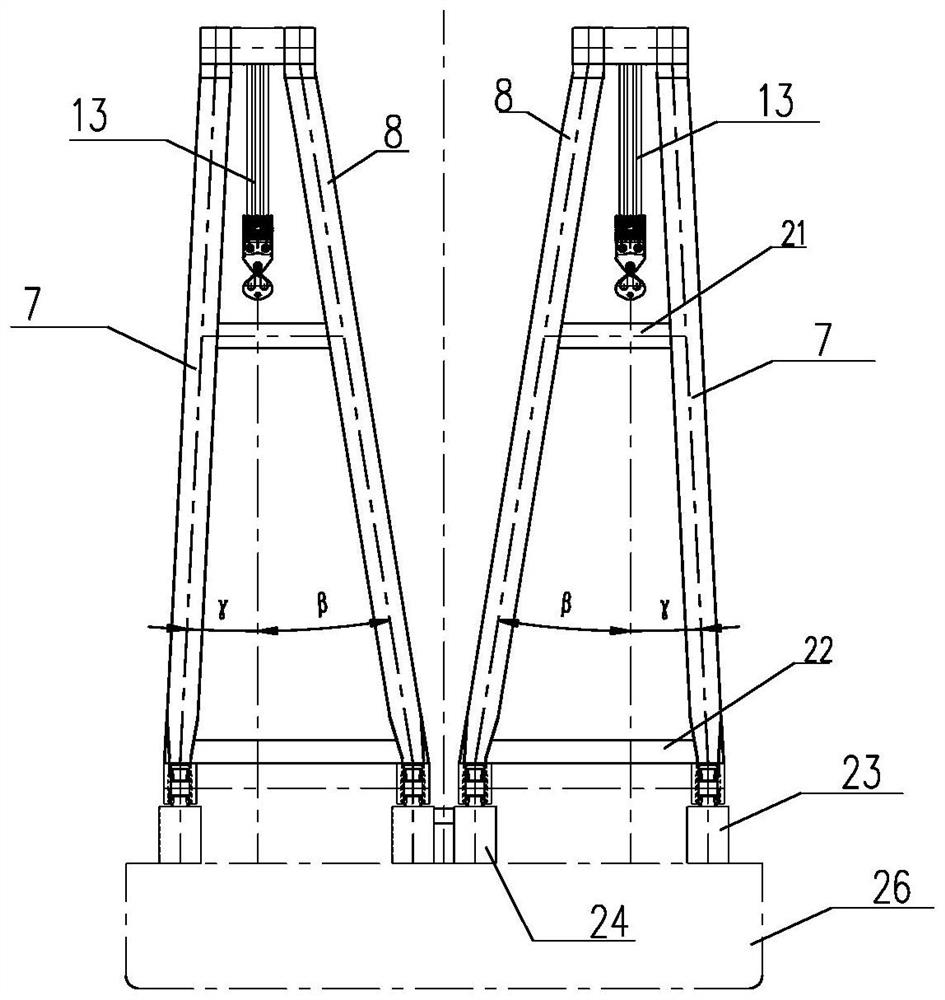

[0040] Such as Figure 1~5 The heavy-duty low-headroom luffing crane shown in the sea is arranged on the deck of the ship, and it includes a single gable assembly arranged on the stern deck and a cross-ship (width direction) arrangement arranged on the bow deck. 2 inverted L-shaped boom assemblies, and the 2 inverted L-shaped boom assemblies are symmetrically arranged on the center line of the deck;

[0041] The single herringbone frame assembly includes two herringbone girders 1 symmetrically arranged on the center line of the ship deck, and the tops of the two herringbone girders 1 are connected to the main beam 2,

[0042] The herringbone truss 1 is composed of a vertical rear tie rod 1.1 and an inclined front strut 1.2. The angle between the top of the rear tie rod 1.1 and the front strut 1.2 is 35°; Rod 1.3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com