Sprayer for burn department

A sprayer and installation tube technology, which is applied in the direction of nebulizers for treatment, medical devices, medical devices, etc., can solve the problems of drug spraying, the inability to adjust the temperature of the liquid medicine according to the demand, and the waste of the liquid medicine, so as to avoid slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

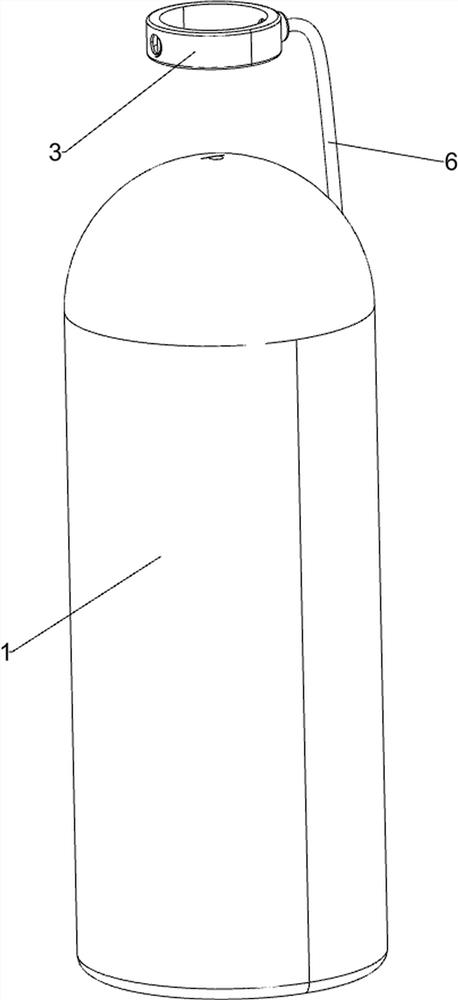

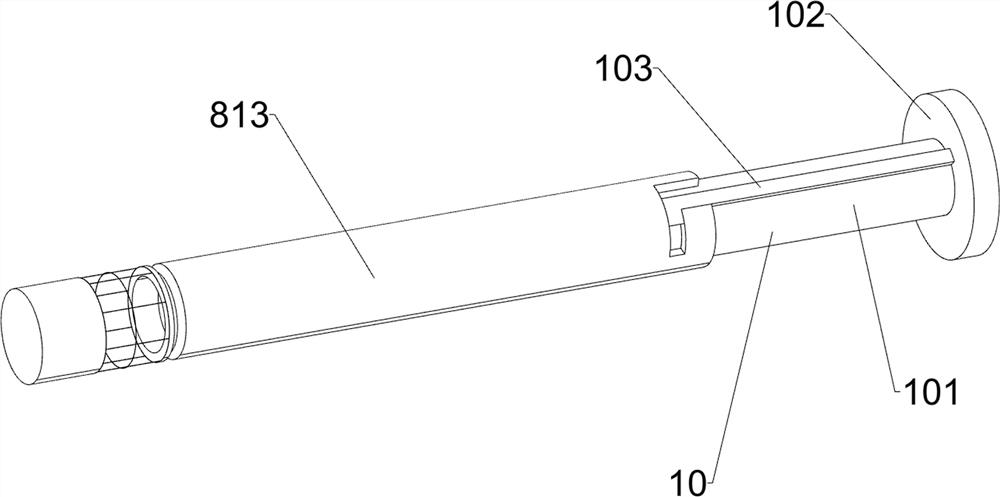

[0027] A nebulizer for burns, such as Figure 1-9 As shown, it includes a bottle body 1, an installation cylinder 2, a ring 3, an atomizing nozzle 4, a housing 5, a hose 6, an extrusion mechanism 7 and a heating mechanism 8, and the top of the bottle body 1 is provided with an installation cylinder 2. The upper part of the tube 2 is provided with a circular ring 3, the left side of the circular ring 3 is provided with an atomizing nozzle 4, the right side of the circular ring 3 and the bottle body 1 is provided with a housing 5, and the right side of the circular ring 3 is provided with a hose 6. The tube 6 has a one-way valve, the installation cylinder 2 is provided with an extruding mechanism 7 , and the installation cylinder 2 is provided with a heating mechanism 8 .

[0028] When using this device, the staff sucks the liquid in the bottle body 1 into the hose 6 through the extrusion mechanism 7, and the liquid in the hose 6 enters the ring 3 and is sprayed out through the ...

Embodiment 2

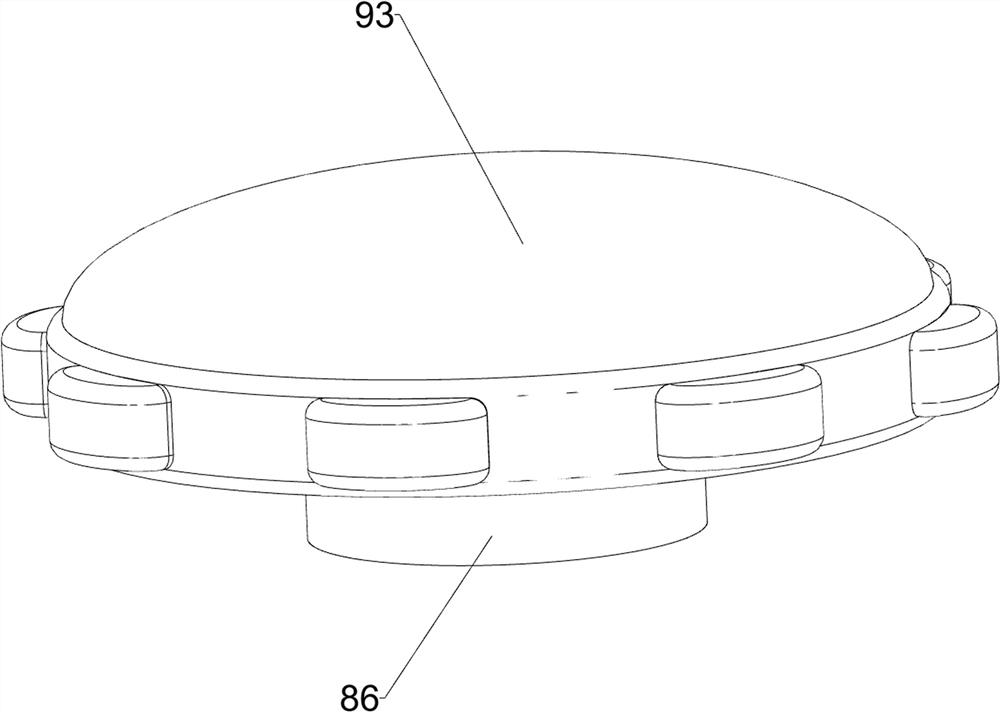

[0034] On the basis of Example 1, such as figure 1 , Figure 7 and Figure 8 As shown, it also includes a rotating mechanism 9, the rotating mechanism 9 includes a push block 91, a second block 92 and a handle 93, the top of the installation block 86 is symmetrically provided with a push block 91, and the top of the installation cylinder 2 is symmetrically provided with a second block. Both the stopper 92 and the second stopper 92 cooperate with the pusher 91 , and a handle 93 is provided on the top of the installation block 86 .

[0035] When using the device, the staff turns the handle 93, the handle 93 rotates to drive the installation block 86 to rotate, and the rotation of the installation block 86 drives the push block 91 to rotate. When the push block 91 rotates to contact with the second block 92, the second block 92 limits the pushing block 91, so that it is more convenient for the staff to rotate the mounting block 86.

[0036] On the basis of Example 1, such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com