Bean sprout auxiliary planting device

A planting device and technology of bean sprouts, applied in botany equipment and methods, soilless cultivation, cultivation, etc., can solve problems such as automatic planting of difficult bean sprouts and rational management of difficult bean sprouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

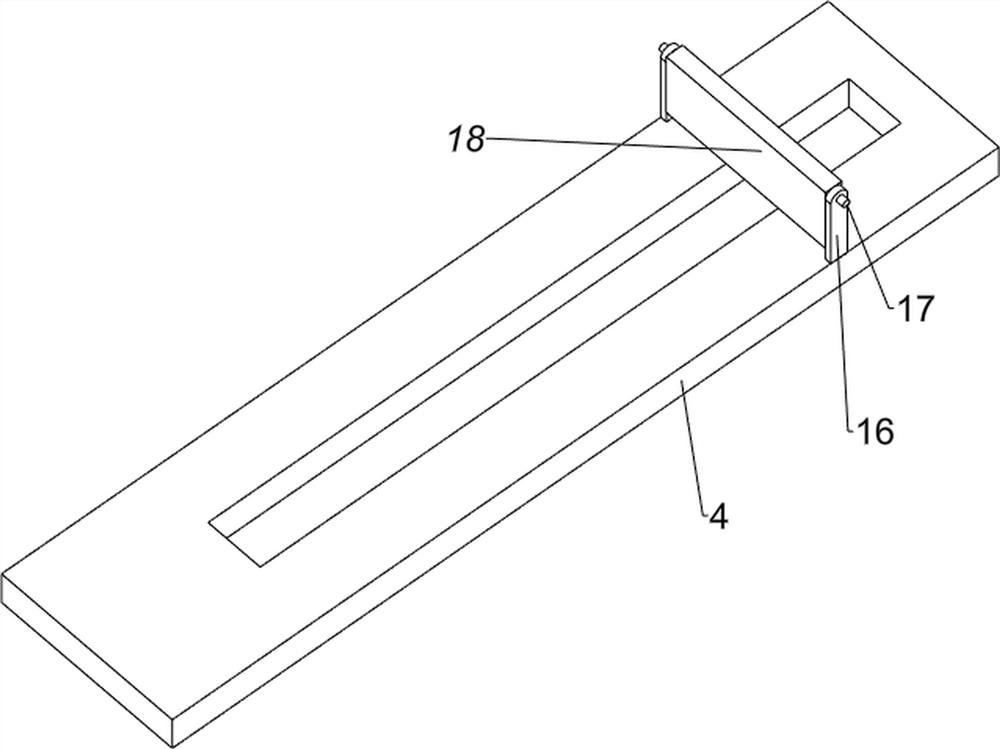

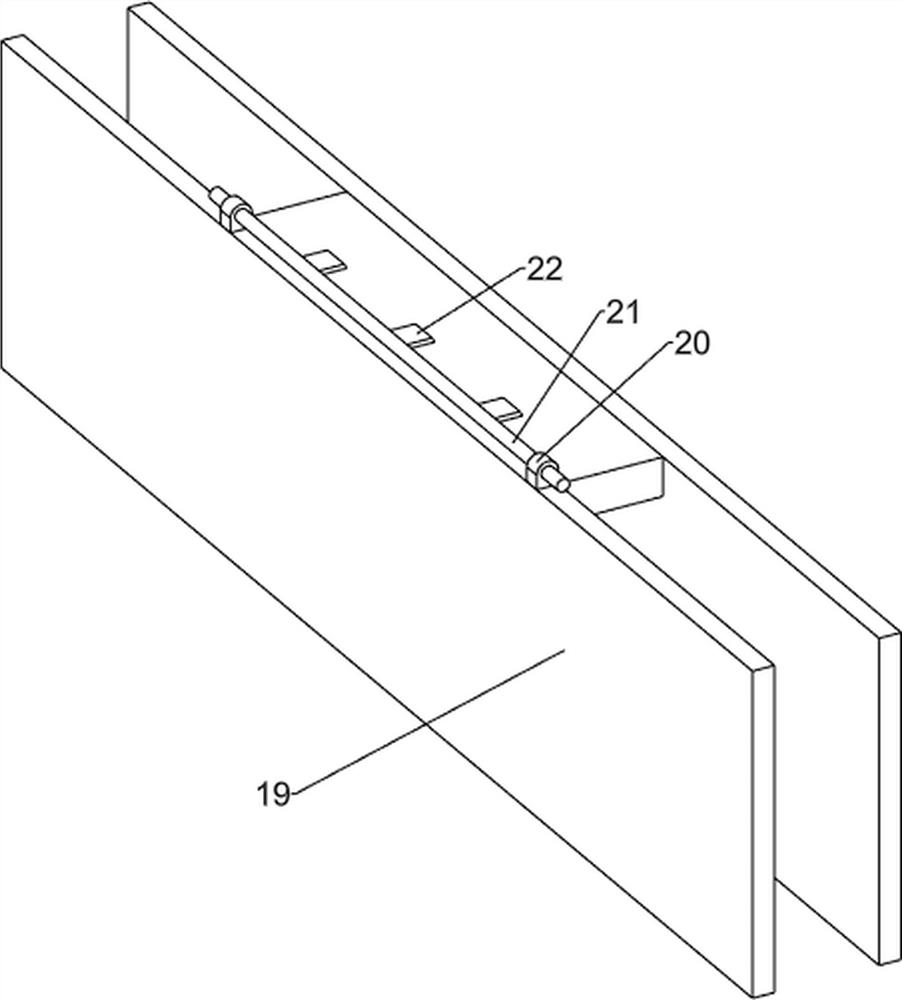

[0028] A bean sprouts auxiliary planting device, such as Figure 1-3 As shown, it includes a support frame 1, a support platform 2, a transmission mechanism 3, a material pushing mechanism 5, a material pushing plate 6, a sand storage bucket 7, a second conveyor belt 8, a first baffle plate 9, a slide plate 10, and a bean storage bucket 11 And stage 12, support frame 1 top right front side is provided with support platform 2, support platform 2 is provided with transmission mechanism 3, support platform 2 top left side is provided with special-shaped plate 4, support frame 1 left front side and transmission mechanism 3 A pusher mechanism 5 is arranged between them, and a pusher plate 6 is arranged on the pusher mechanism 5, and a sand storage bucket 7 is arranged on the left front side of the support frame 1, and two third rotating shafts are connected to the left side of the support frame 1 in a rotary manner, and the third A second conveyor belt 8 is wound around the rotatin...

Embodiment 2

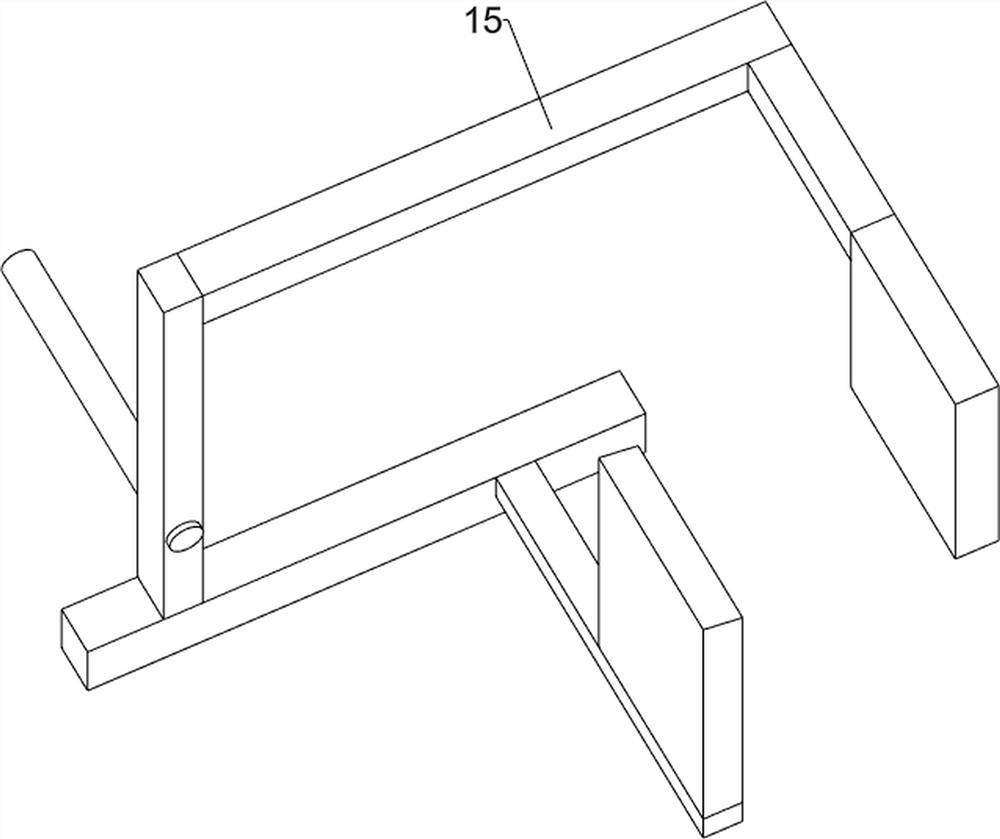

[0033] On the basis of Example 1, such as Figure 4-10 As shown, it also includes a cam 13, a fixed rod 14 and a material partition plate 15. The front side of the first rotating shaft 304 is provided with a cam 13, and the left front side of the support table 2 is rotatably connected with a fixed rod 14. The material plate 15, the material separating plate 15 and the special-shaped plate 4 are slidingly connected.

[0034] The first rotating shaft 304 rotates and drives the cam 13 to constantly rotate. When the cam 13 squeezes the material dividing plate 15, the left side of the material dividing plate 15 is rotated upwards, so that the seedling raising box rotated by the material dividing plate 15 slides out to the left. When the cam 13 When moving away from the material separating plate 15, the material separating plate 15 rotates and resets due to gravity, so that the material separating plate 15 blocks the seedling raising box, and the effect of feeding at intervals can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com