Tomato picking robot capable of self-adapting to different heights

A picking robot and self-adaptive technology, applied in picking machines, applications, harvesters, etc., can solve the problems of inconvenient disassembly, high cost, high labor intensity, etc., and achieve the effect of convenient disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

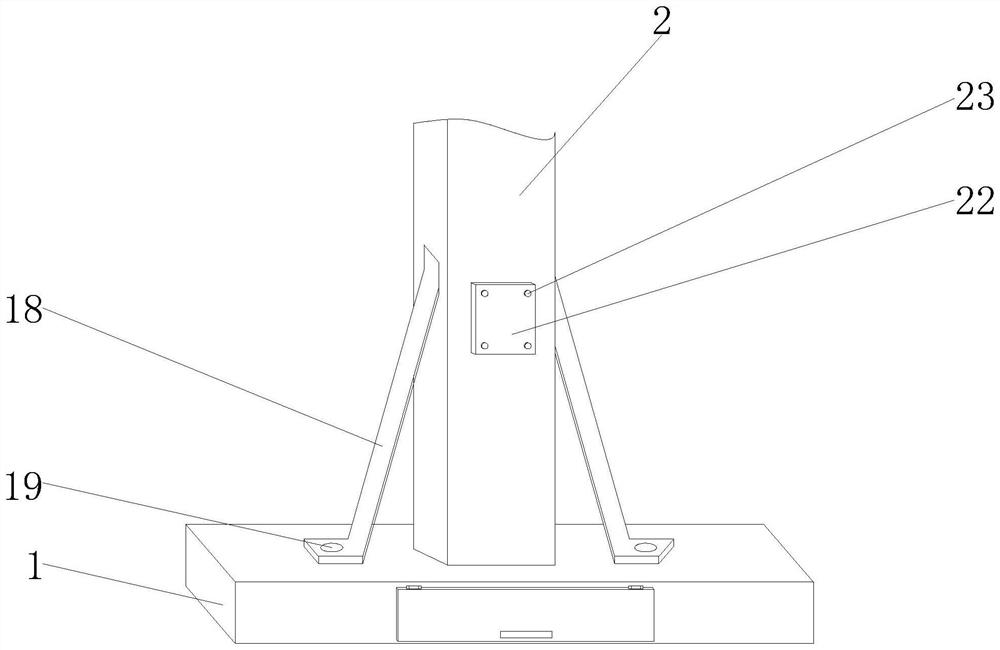

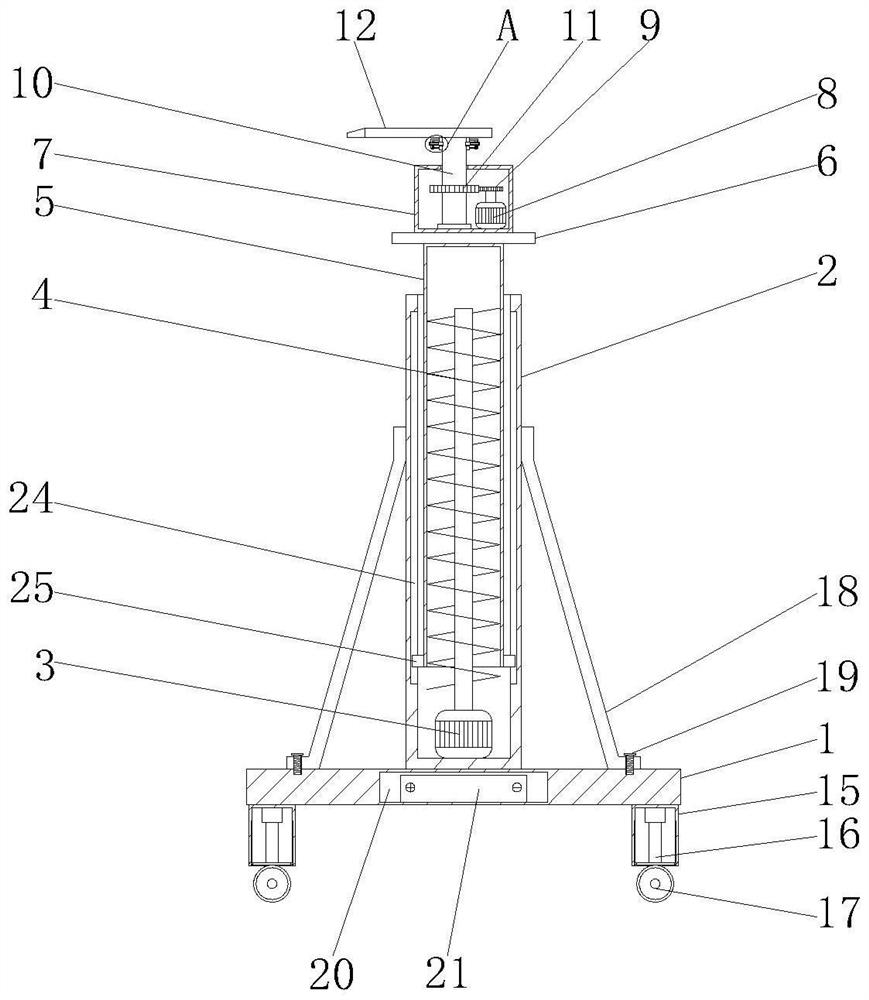

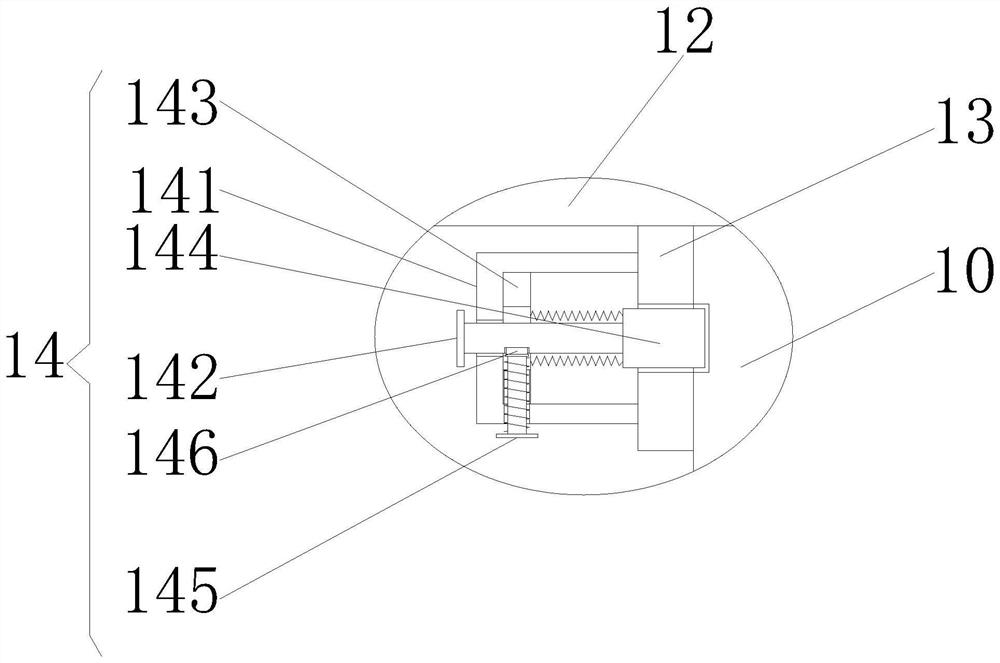

[0019] Such as Figure 1-Figure 3 As shown, a tomato picking robot that can adapt to different heights provided by the present invention includes a base 1, a support rod 2 is arranged on the top of the base 1, and a first motor 3 is fixedly connected to the bottom of the inner cavity of the support rod 2. The top of the motor 3 is fixedly connected with a threaded rod 4, the surface of the threaded rod 4 is covered with a threaded pipe 5, the top of the threaded pipe 5 extends to the outside of the support rod 2, and the top of the threaded pipe 5 is fixedly connected with a horizontal plate 6, the horizontal plate The top of 6 is fixedly connected with a placement box 7, the right side of the inner cavity of the placement box 7 is fixedly connected with a second motor 8, the top of the second motor 8 is fixedly connected with a first gear 9, and the inside of the placement box 7 is provided with a connecting rod 10 , the bottom of the connecting rod 10 is movably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com