Multi-state configuration method for assembly tool

An assembly tooling and multi-state technology, applied in aircraft assembly, instruments, manufacturing computing systems, etc., can solve problems such as unclear technical state management, reduce time and errors, improve changeover efficiency, and eliminate changeover errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

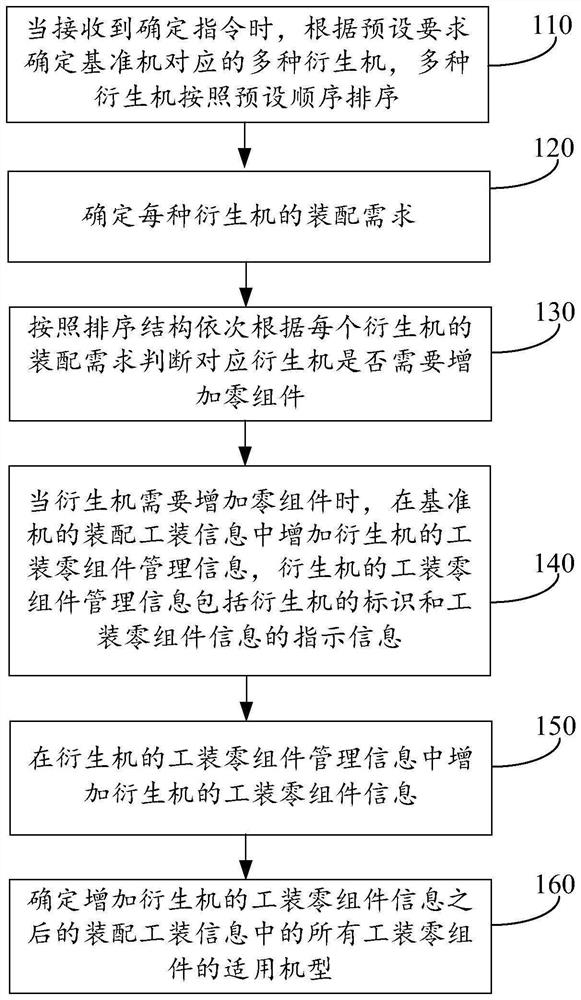

[0032] This application provides a multi-state configuration method for assembly tooling, which is used for electronic equipment. For example, the electronic equipment can be a computer, such as figure 1 As shown, the method includes:

[0033] Step 110, when receiving the determination instruction, determine various derived machines corresponding to the reference machine according to preset requirements, and the various derived machines are sorted according to a preset order.

[0034] Step 120, determining the assembly requirements of each derivative machine.

[0035] Step 130 , according to the sorting structure, judge whether the corresponding derivative machine needs to add components according to the assembly requirements of each derivative machine.

[0036] Step 140, when the derivative machine needs to add parts and components, add the tooling component management information of the derivative machine to the assembly tooling information of the reference machine, the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com