Optical imaging lens

An optical imaging lens and imaging technology, applied in optics, optical components, instruments, etc., can solve the problems of increased design difficulty and increased design difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

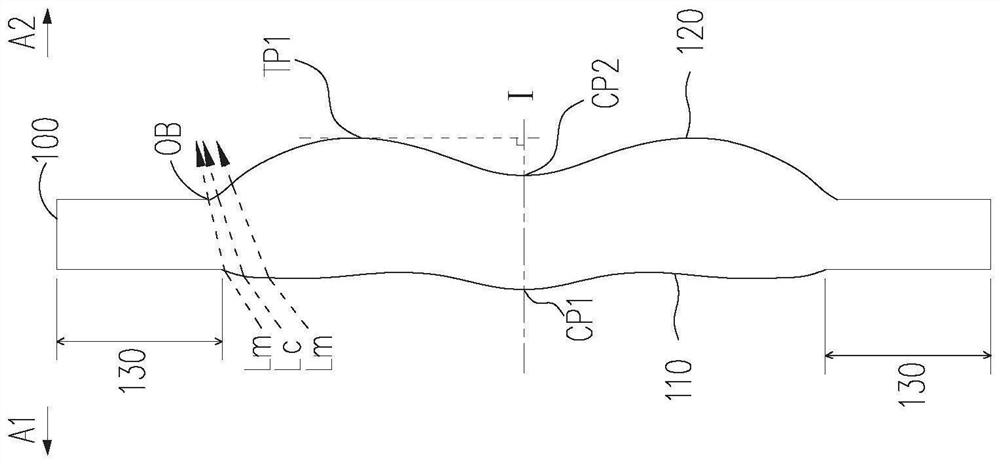

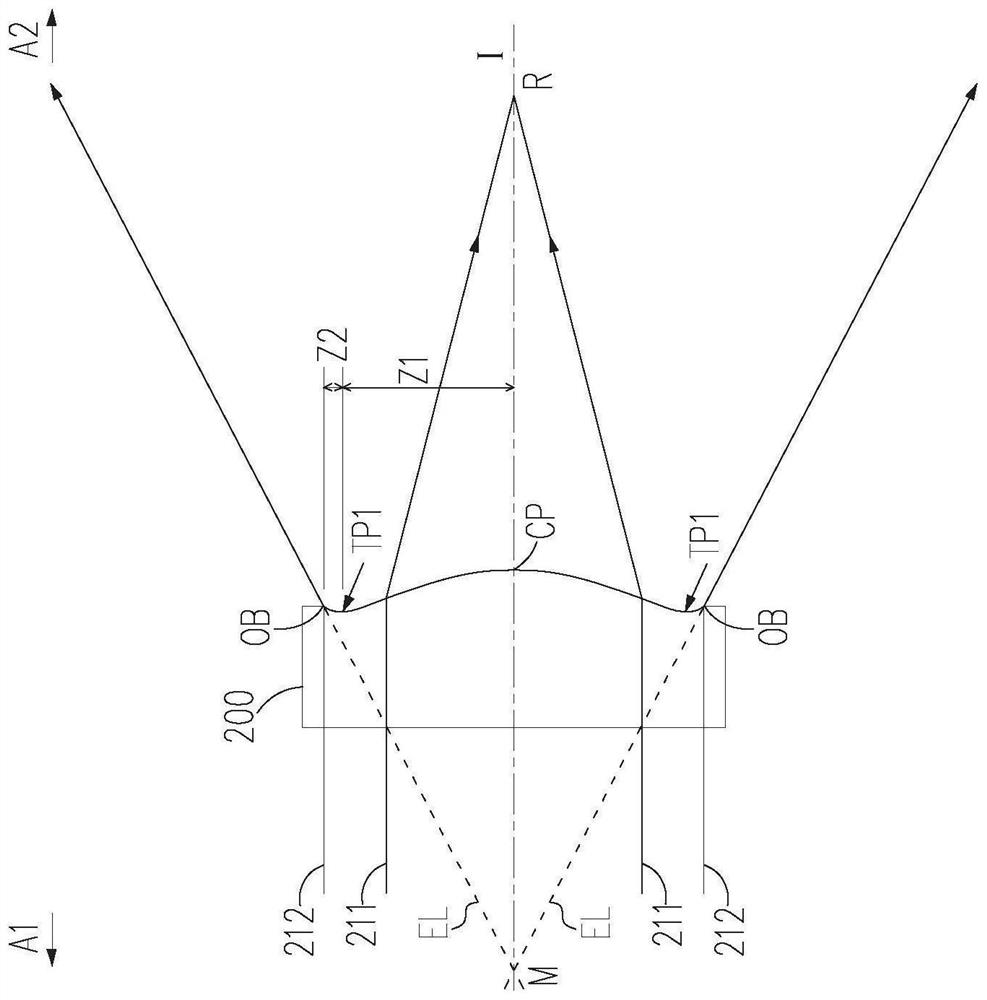

[0083] see Figure 6 , illustrating the first embodiment of the optical imaging lens 1 of the present invention. For the longitudinal spherical aberration (longitudinal spherical aberration) on the imaging surface 4 of the first embodiment, please refer to Figure 7 For A, the field curvature aberration in the sagittal direction, please refer to Figure 7 B, field curvature aberration in the meridian direction, please refer to Figure 7 C, and distortion aberration (distortion aberration), please refer to Figure 7 D. The Y-axis of each spherical aberration diagram in all embodiments represents the field of view, and its highest point is 1.0. The Y-axis of each aberration diagram and distortion aberration diagram in the embodiments represents the image height. The image height of the first embodiment (Image Height, ImgH) is 5.467 mm.

[0084] The optical imaging lens 1 of the first embodiment is mainly composed of eight lenses with refractive power, an aperture 2 , and an...

no. 2 example

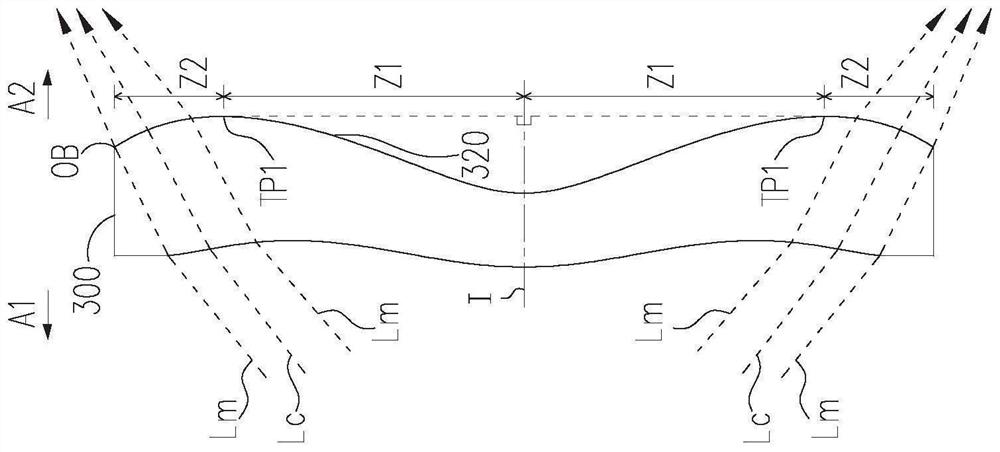

[0097] see Figure 8 , illustrating the second embodiment of the optical imaging lens 1 of the present invention. Please note that starting from the second embodiment, in order to simplify and clearly express the drawings, only the optical axis area and the circumferential area of each lens that are different from the first embodiment are specially marked on the figure, while the rest are the same as those of the first embodiment. The optical axis area and the circumferential area of the same surface shape of the lens, such as concave or convex, are not marked separately. For the longitudinal spherical aberration on the imaging surface 4 of the second embodiment, please refer to Figure 9 A, field curvature aberration in the sagittal direction, please refer to Figure 9 B, field curvature aberration in the meridional direction, please refer to Figure 9 For C, distortion aberration, please refer to Figure 9 D. The design of the second embodiment is similar to that of...

no. 3 example

[0100] see Figure 10 , illustrating the third embodiment of the optical imaging lens 1 of the present invention. For the longitudinal spherical aberration on the imaging surface 4 of the third embodiment, please refer to Figure 11 A, field curvature aberration in the sagittal direction, please refer to Figure 11 B, field curvature aberration in the meridional direction, please refer to Figure 11 For C, distortion aberration, please refer to Figure 11 D. The design of the third embodiment is similar to that of the first embodiment, except that related parameters such as lens refractive power, lens curvature radius, lens thickness, lens aspheric coefficient, or back focus are different.

[0101] The detailed optical data of the third embodiment are as Figure 24 As shown, the aspheric data such as Figure 25 As shown, in this embodiment, EFL=8.647 mm; HFOV=40.842 degrees; TTL=9.384 mm; Fno=1.909; ImgH=5.742 mm. In particular: 1. The system length TTL of this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com