Air supply combustion-supporting structure for grate furnace

A technology of grate furnace and grate sheet, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of low crushing efficiency of turning materials, inability to adjust the looseness of turning materials, etc., and achieve better combustion effect and looseness. Small, better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, a technical scheme in the embodiment of the present invention will be described in the following examples, which is apparent from the embodiments of the present invention, and is merely the embodiments of the present invention, not all of Embodiments in the present invention, those of ordinary skill in the art are in the range of protection of the present invention without making creative labor.

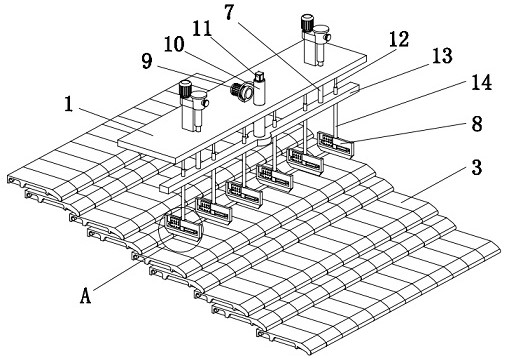

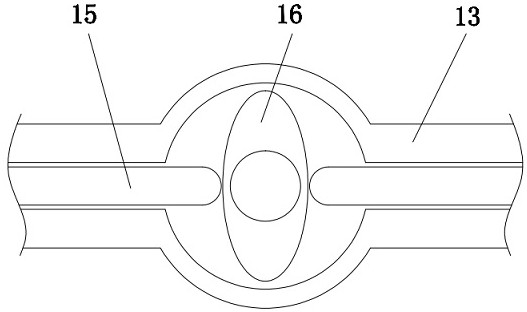

[0031] Append Figure 1-10 As shown, a furnace furnace is blown to a furnace, including a furnace body 1, a feed strip 2 on the left side of the furnace body 1, and the feed strip 2 is used for the feed, and the furnace body 1 is also inclined. Volume 3, the furnace drain 3 is divided into a dynamic furnace drain and a discharge, the moving furnace drain and the fixing drain block, the moving furnace drain reciprocating moves to move the combustion material to the right side, and the furnace pieces 3 on the right side of the furnace pieces are connected There is a grade resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com