Variable eccentric hard sealing butterfly valve

A hard-sealing, eccentric technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of reducing working pressure, increasing valve opening and closing torque, poor reverse sealing performance of hard-sealing butterfly valves, etc., to improve sealing performance. , The effect of reducing the opening and closing torque and reducing the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

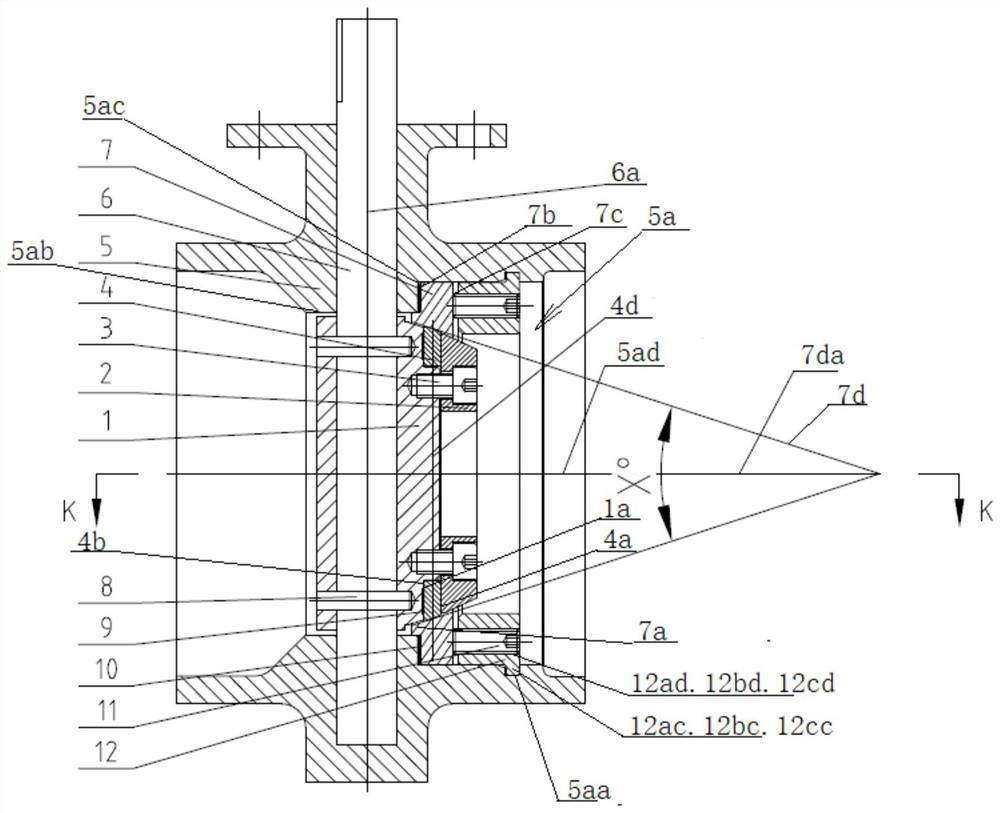

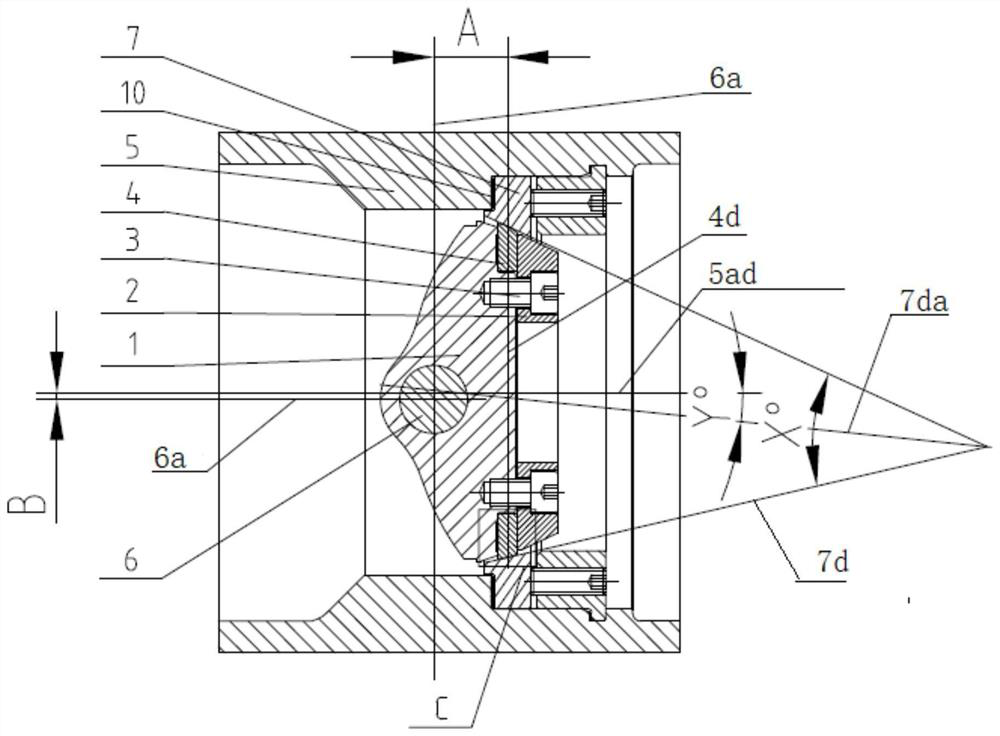

[0037]Please refer to the accompanying drawings and further describe the present invention:

[0038] see figure 1 and figure 2 , a variable eccentric hard seal butterfly valve shown in the figure is mainly composed of a butterfly plate 1, a pressure plate 2, a screw 3, a sealing ring 4, a valve body 5, a valve stem 6, a valve seat 7, a pin 8, and a first gasket 9 , The second gasket 10, the set screw 11, and the three open rings 12 are composed.

[0039] The valve body 5 is provided with a valve body channel hole 5a for fluid to flow through. A three-open ring 12 is installed in the valve body flow channel hole 5a. The function of the three open rings 12 is mainly to facilitate the movable installation of the valve seat 7 in the valve body flow channel hole 5a. At the same time, it is convenient for the valve seat 7 to be disassembled from the valve body 5 for easy replacement and adjustment.

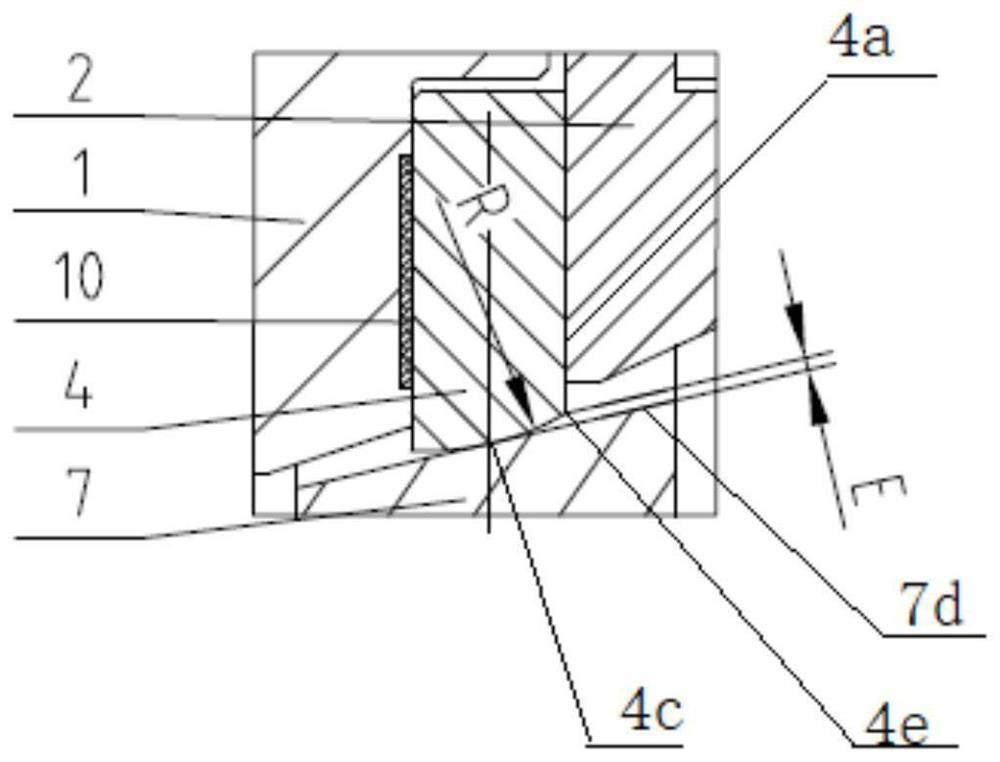

[0040] see Figure 4 and Figure 5 , the structure and installation method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com