Quenching furnace device capable of realizing continuous quenching of multiple samples

A quenching furnace and multi-sample technology, applied in the field of quenching furnace, can solve the problems of affecting the quenching processing efficiency, heating time extension, temperature fluctuation, etc., and achieve the effect of improving efficiency, ensuring accuracy and ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

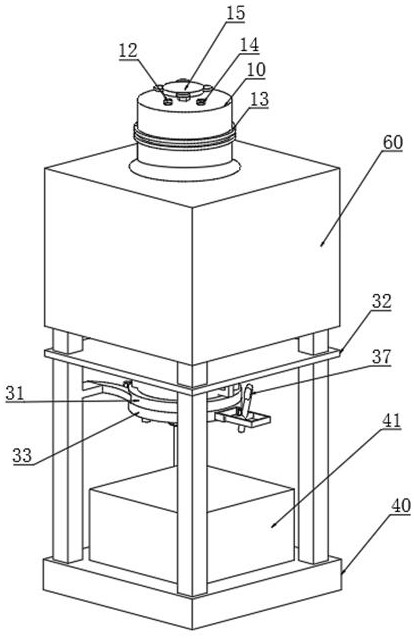

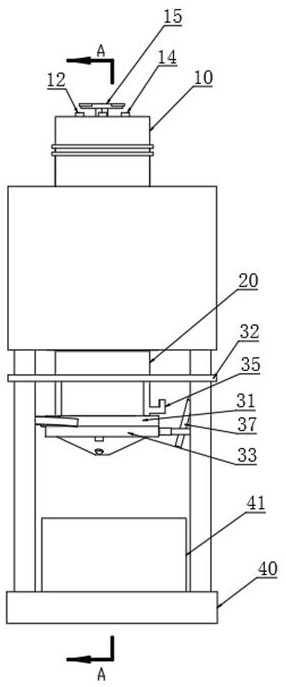

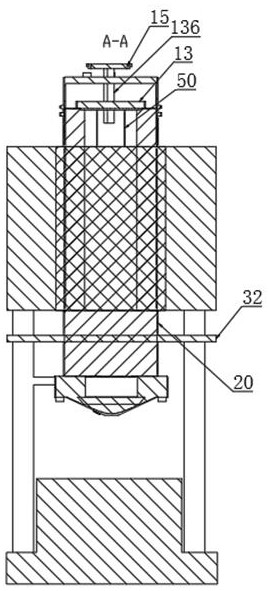

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] see Figure 1-Figure 9 , when the present invention is mainly aimed at quenching the workpieces or test samples that need to be heated to the same temperature and held for different times, the samples with a longer holding time are heated together with the samples with a shorter holding time in the early stage, so that the heating time can be saved and the quenching process can be greatly improved. Efficiency, and ensure that the quenching process has no effect on other heated samples. The total holding time is the holding time of the sample with the longest holding time. It can also be used to study the influence of different media on the quenching performance. The same media samples are taken as a group, and when they are heated at the same time, the media is quickly switched to conduct a quenching comparison test.

[0034] A quenching furnace devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com